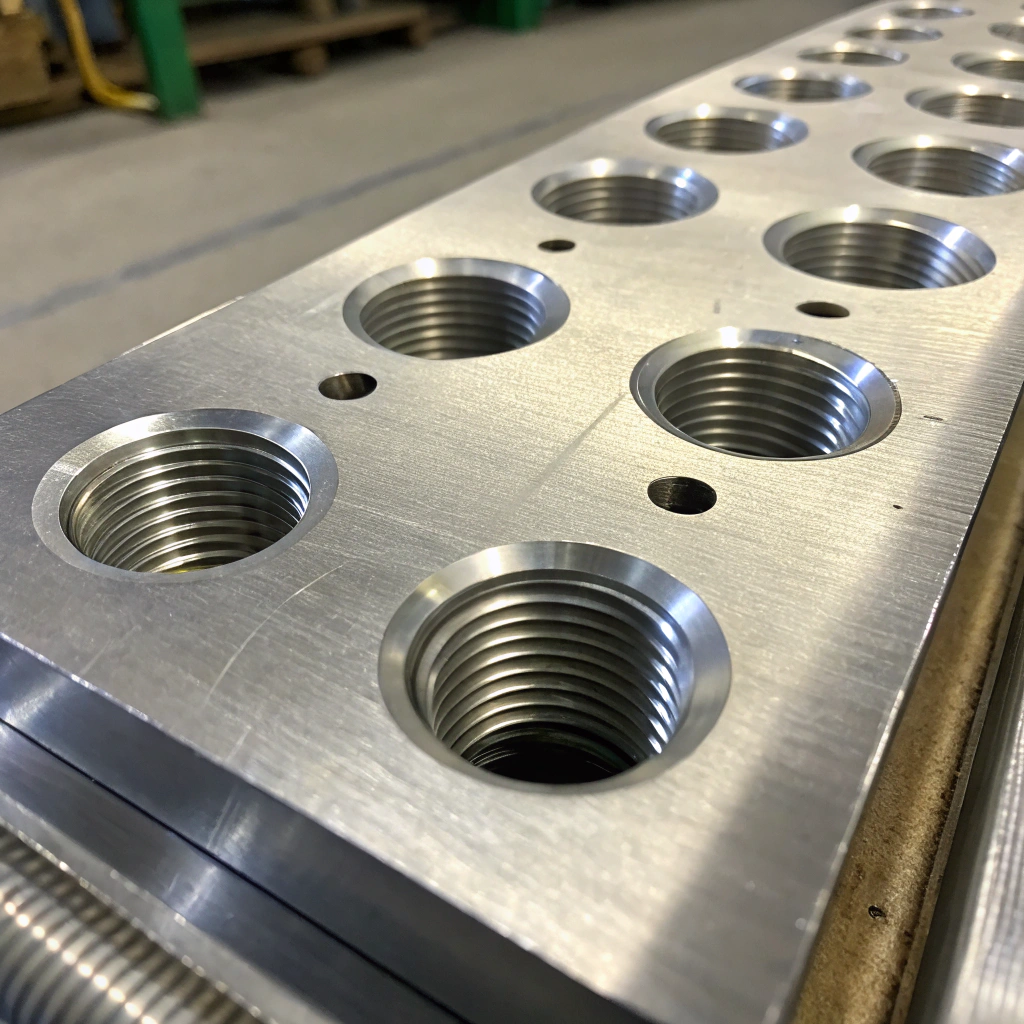

Threaded holes are holes with internal threads that allow for the insertion of screws, bolts, or other fasteners, creating a strong mechanical connection between parts. These threads are precision-cut into the hole's interior, enabling it to hold fasteners securely in place. Threaded holes are commonly used in a variety of applications, from machinery and automotive to electronics and construction.

Threaded holes are essential components in assembly processes where parts need to be joined securely. They provide a durable connection by creating a tight fit between the fastener and the hole, ensuring that the components remain stable under stress.

The types of threaded holes vary depending on the fasteners being used, and the process of creating them is critical to ensure the correct alignment and strength of the final assembly.

What Are the Benefits of Using Threaded Holes?

Threaded holes offer numerous advantages in mechanical design and assembly. They are commonly used in applications where a strong, durable, and reusable connection is needed. From providing better strength to reducing the need for additional hardware, threaded holes offer a reliable and efficient solution for joining parts.

The benefits of using threaded holes include improved joint strength, ease of assembly, and the ability to easily replace or adjust components. Here are some of the key advantages of threaded holes in mechanical and industrial applications.

Secure and Strong Connections

Threaded holes create a strong bond between parts, making them ideal for applications where the connection must withstand high stresses, vibrations, or loads. Fasteners like bolts or screws can be inserted into the threaded hole, and the tight fit of the threads ensures a secure connection that is resistant to loosening over time.

Reusability

One of the significant advantages of threaded holes is their ability to accommodate fasteners multiple times. Unlike other methods of joining parts, threaded holes can be reused, allowing components to be disassembled and reassembled without compromising the integrity of the connection. This reusability is crucial in applications where maintenance or adjustments are needed.

Precision and Adjustability

Threaded holes offer high precision, allowing for exact alignment between parts. This precision is essential in manufacturing and assembly, as it ensures that fasteners fit correctly and securely. Additionally, threaded holes allow for adjustability; parts can be tightened or loosened as needed, offering flexibility in various mechanical systems.

Cost-Effectiveness

Using threaded holes reduces the need for additional hardware, such as nuts or welding, which can lower the overall cost of production. By eliminating the need for these extra components, threaded holes streamline the assembly process and minimize the number of parts required for the final product.

Simplified Assembly Process

Threaded holes can simplify the assembly process by allowing for direct insertion of fasteners. This reduces the need for complex alignment tools and fixtures, making assembly faster and more efficient. Threaded holes are especially useful in automated or mass production environments where speed and accuracy are key.

How to Design and Machine Threaded Holes?

Designing and machining threaded holes requires careful consideration of several factors, including the type of threads, hole dimensions, and machining techniques. A well-designed threaded hole ensures that the fastener fits securely and performs effectively in the assembly. The machining process must also be precise to avoid issues like thread damage or misalignment.

To design and machine threaded holes correctly, it’s essential to understand the specifications of the threads, the type of material being used, and the appropriate machining methods. Here are the steps involved in designing and machining threaded holes.

Step 1: Choose the Right Thread Type

The first step in designing a threaded hole is to select the appropriate thread type for the application. Common thread types include:

- Metric Threads (M): Used in most modern applications, especially in Europe and Asia.

- Unified Threads (UNC, UNF): Used primarily in the United States.

- BSP (British Standard Pipe): Used in plumbing and fluid applications.

- Acme Threads: Used for power transmission applications where linear movement is required.

The choice of thread type depends on the required strength, material compatibility, and application requirements.

Step 2: Determine Hole Dimensions

The dimensions of the threaded hole are crucial to ensuring the proper fit for the fastener. The key dimensions to consider are:

- Hole Diameter: The hole must be slightly smaller than the outer diameter of the fastener to ensure that the threads fit correctly. The diameter must be precisely calculated based on the type of thread being used.

- Thread Depth: The depth of the threads affects the strength of the connection. A deeper thread generally provides a stronger bond but may increase the machining time.

For example, the thread depth and diameter for a metric M6 screw would differ from that of a standard M8 screw. Accurate calculations for these dimensions are essential.

Step 3: Select the Right Machining Method

Several machining methods can be used to create threaded holes, including:

- Tapping: A process in which a cutting tool (tap) is used to create threads in a pre-drilled hole. Tapping is the most common method for creating threaded holes in metal.

- Drilling and Reaming: A hole is drilled to the desired diameter, then reamed to achieve a smooth, precise surface before threading.

- Thread Milling: A process that uses a rotating tool to cut threads into a hole. This method is ideal for larger holes or when high precision is required.

The choice of method depends on factors such as hole size, material hardness, and the level of precision required.

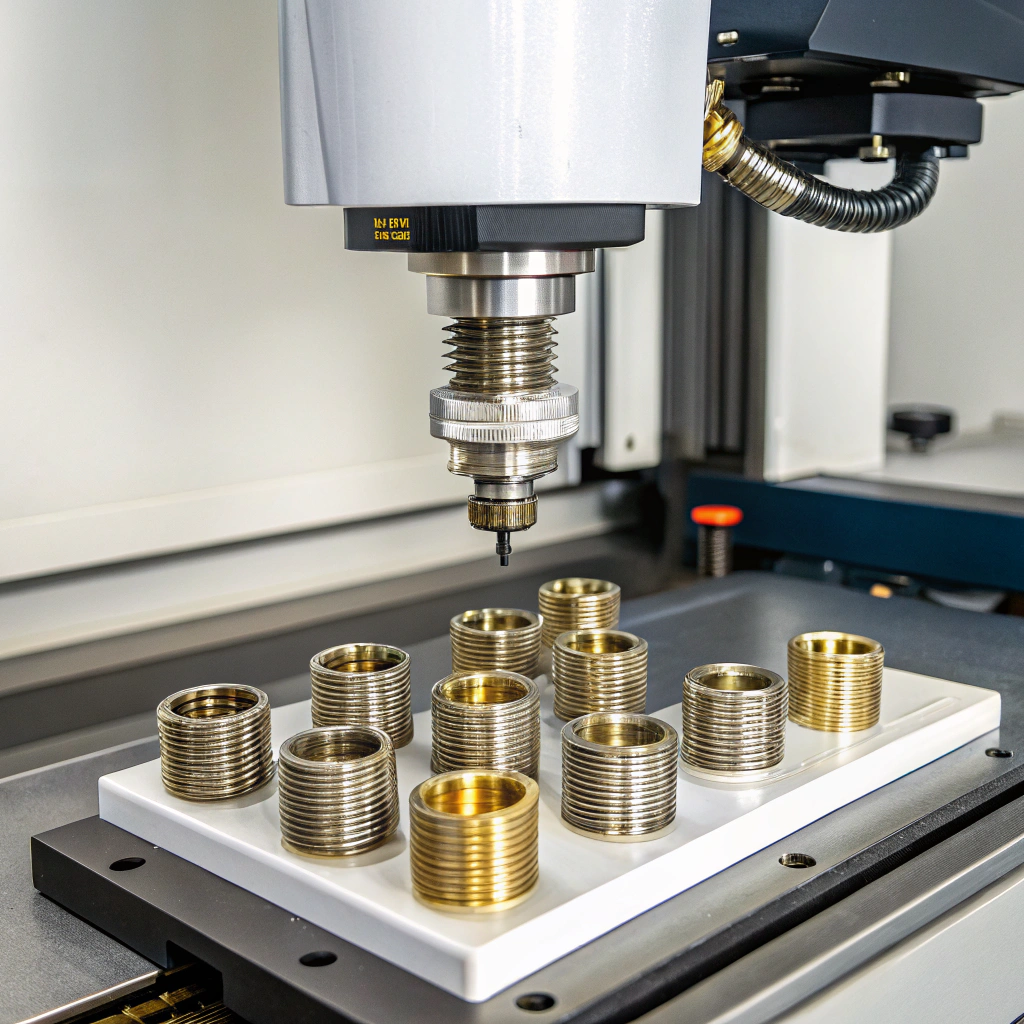

Step 4: Verify Thread Quality

After machining the threaded hole, it’s crucial to verify the thread quality. This can be done using thread gauges or by measuring the fit of the fastener in the hole. Poorly machined threads can result in weak connections, fastener slippage, or difficulty during assembly.

Step 5: Consider Surface Finish and Treatment

For added strength and resistance to wear and corrosion, threaded holes may need post-machining treatments such as coating, plating, or anodizing. These treatments can improve the performance of threaded holes, especially in harsh environments like automotive or aerospace applications.

What Are the Trends in Threaded Hole Technology?

As technology advances, the methods for creating and utilizing threaded holes are evolving. New techniques are making threaded holes more efficient, precise, and cost-effective, while new materials and coatings are improving their performance.

Recent trends in threaded hole technology focus on automation, advanced materials, and improved precision. These developments are driving the future of threaded hole design and manufacturing, offering new opportunities for innovation in industries like automotive, aerospace, and electronics.

Automation in Threaded Hole Production

Automation is increasingly being used in the manufacturing of threaded holes. CNC machines and robotic systems are being employed to automate the process of drilling and tapping, increasing production speed and consistency. Automated systems can also reduce human error, ensuring that threaded holes meet precise specifications.

Additive Manufacturing and Threaded Inserts

Additive manufacturing (3D printing) is making its way into threaded hole technology, particularly for creating threaded inserts that can be integrated directly into 3D-printed parts. This eliminates the need for post-processing and allows for the creation of custom threaded holes in complex geometries that were previously difficult to achieve with traditional methods.

Use of Advanced Coatings

To enhance the performance of threaded holes, manufacturers are increasingly using advanced coatings. For example, coatings like titanium nitride (TiN) can be applied to threaded holes to improve wear resistance, reduce friction, and prevent corrosion. These coatings are particularly useful in high-stress applications like aerospace and automotive manufacturing.

Smart Manufacturing and Thread Monitoring

The rise of smart manufacturing technologies is enabling real-time monitoring and control of threaded hole production. Sensors and data analytics can be used to track the quality of threaded holes during machining, ensuring that they meet specifications without the need for manual inspection. This trend is making threaded hole production more efficient and reducing the risk of errors.

Sustainable Manufacturing Practices

As sustainability becomes more important in manufacturing, there is a push to reduce waste and energy consumption in threaded hole production. Techniques such as precision machining, which reduces material waste, and the use of recyclable materials are helping make threaded hole manufacturing more eco-friendly.

Conclusion

In conclusion, threaded holes are essential components in mechanical assemblies, providing strong, secure connections that are reusable and precise. Proper design, machining, and verification are crucial to ensuring the success of threaded holes in various applications. As trends in automation, 3D printing, and advanced coatings continue to evolve, the technology behind threaded holes will only become more efficient, precise, and adaptable to future manufacturing needs.