Modern manufacturing is under constant pressure—faster lead times, tighter tolerances, and complex shapes are just the start. How do we keep up with all that?

A 3-axis CNC machine is a computer-controlled tool that moves along three directions—X, Y, and Z—to perform cutting, drilling, and milling tasks. It's the simplest and most common type of CNC.

Most people have heard the term "CNC," but few understand how these machines actually work. To get the most value out of a CNC machine, it’s crucial to understand the differences between 3-axis, 4-axis, and 5-axis systems. Let’s start with the basics.

How does a 3-axis CNC machine work?

Manufacturers often face a challenge: creating consistent parts with complex shapes without human error. Manual tools just can’t match up.

A 3-axis CNC machine works by moving the cutting tool or workpiece in three linear directions—left-right (X), forward-backward (Y), and up-down (Z)—to shape the material.

The machine follows commands from a pre-programmed design file, usually a G-code. The toolpath is generated in software like Fusion 360 or Mastercam. The three-axis system provides basic but accurate movement.

Components of a 3-Axis CNC Machine

| Component | Description |

|---|---|

| Spindle | Rotates the cutting tool at high speeds. |

| Worktable | Holds the workpiece in place. |

| Drive Motors | Move the spindle or table along X, Y, Z axes. |

| Control Unit | Reads G-code and controls movement. |

Step-by-Step Operation

- CAD Model: A 3D model of the part is created.

- CAM Processing: The model is translated into toolpaths.

- G-code Generation: Instructions are generated for the machine.

- Machining: The tool follows the path and cuts the material.

This setup is ideal for flat parts or parts where only one face needs machining. It's also common for short-run production and prototyping.

Why are 3-axis CNC machines used in basic machining?

Precision, speed, and cost-efficiency often feel like a trade-off. But not with 3-axis CNC.

3-axis CNC machines are used in basic machining because they offer accurate, repeatable results at a lower cost and are easy to set up and operate.

For many simple operations—such as cutting flat plates, drilling holes, or trimming rectangular shapes—3-axis is more than enough. The process is straightforward and doesn’t require highly skilled operators. The machines are also less expensive and easier to maintain.

Benefits of 3-Axis CNC Machines

| Benefit | Description |

|---|---|

| Lower cost | Entry-level pricing and lower maintenance costs. |

| Easy programming | Simple G-code files, easy for beginners. |

| Broad availability | Widely used in most machine shops. |

| Short learning curve | Operators can get up to speed quickly. |

Ideal Use Cases

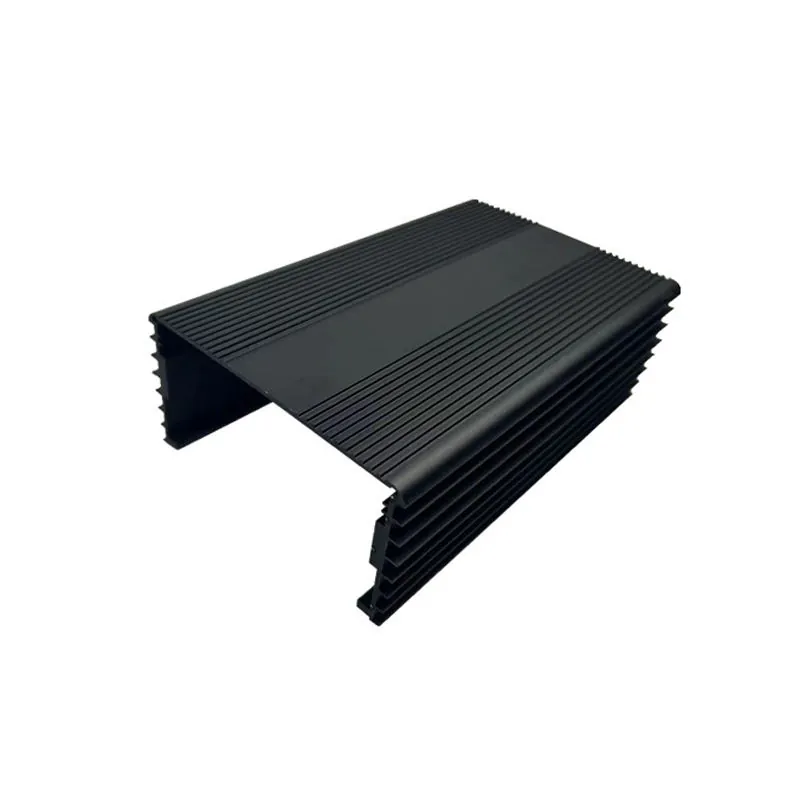

- Cutting aluminum profiles

- Drilling repeated holes in flat parts

- Milling slots or pockets

- Creating flat surface contours

These machines are great for entry-level CNC work and general-purpose manufacturing. In large factories, they’re often used for the first step in multi-stage processes.

What types of parts can be made with a 3-axis CNC?

When starting a CNC project, one of the most common questions is: what can this machine actually make?

A 3-axis CNC can make parts like brackets, panels, enclosures, mold bases, fixtures, and simple mechanical components. It excels at machining flat and prismatic shapes.

Common Parts Produced

| Part Type | Example Use Case |

|---|---|

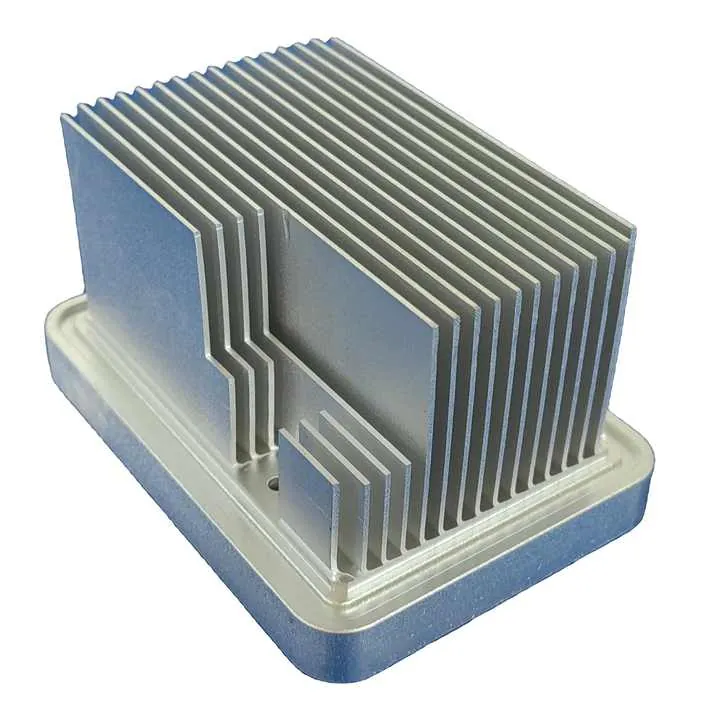

| Brackets | Used in mounting mechanical systems. |

| Panels | Enclosures for electronics or machinery. |

| Plates | Structural components in machines. |

| Fixtures | Holding tools for manufacturing setups. |

| Mold Bases | Flat bottom sections for mold tools. |

Examples from Real Projects

Aluminum Brackets

Aluminum brackets are often used in electronics or machines to hold components. A 3-axis machine can quickly cut the shape, drill holes, and mill slots.

Plastic Enclosures

Flat plastic sheets can be milled into casings for tools or electronic parts. These enclosures require surface flatness and hole accuracy—perfect for 3-axis tools.

Machine Fixtures

Fixtures hold other parts in place during processing. 3-axis machines produce these using repeatable cuts, ensuring parts are stable and aligned during secondary operations.

3-axis machining can handle a wide range of materials like aluminum, copper, plastics, and wood. It's not just for metal parts.

Where is a 3-axis CNC machine commonly used?

Every factory wants to boost output without adding too much complexity. That’s where 3-axis CNC comes in.

3-axis CNC machines are commonly used in workshops, small factories, prototyping labs, and in education for teaching machining principles.

Their compact size and ease of use make them ideal for many industries. While 4-axis and 5-axis machines are great for complex parts, 3-axis machines dominate in volume due to cost and simplicity.

Industries Using 3-Axis CNC Machines

| Industry | Application |

|---|---|

| Manufacturing | Producing brackets, panels, and frames. |

| Education | Teaching CNC fundamentals. |

| Aerospace | Cutting flat parts for assemblies. |

| Automotive | Machining prototypes and fixtures. |

| Electronics | Making plastic and aluminum enclosures. |

Why Smaller Shops Love 3-Axis Machines

- Lower Investment: Perfect for small to medium-sized businesses.

- Fast Setup: You can start production in hours, not days.

- Easy Maintenance: Fewer moving parts than multi-axis machines.

- Flexible Use: Switch between materials with minimal changes.

In educational institutions, they’re used to introduce students to CNC machining. In small-scale industries, they become the backbone of daily production.

Conclusion

3-axis CNC machines are the backbone of modern machining. They balance cost, ease of use, and accuracy. While they have limits, they remain a vital tool for basic manufacturing needs.