When a simple block of metal needs to become a complex part, regular machining can feel like pushing water uphill. It often hits limits in shape or angle. That problem can stall progress or force extra steps.

5‑axis CNC stands for five‑axis computer numeric control machining. It allows a cutting tool or the part to move along five separate axes. That flexibility makes it possible to create complex shapes in one setup. This reduces time, improves precision, and cuts down costs compared to multiple setups or manual finishing.

If you want to understand why 5‑axis CNC changes the game for manufacturing, keep reading. We will look at how it improves part complexity, why some industries need it, what shapes benefit most, and what skills are required to operate it well.

How does 5-axis machining improve part complexity?

When part geometry becomes complicated, ordinary tools struggle to reach all surfaces. That limitation creates error, waste, or additional work. This challenge can bog down projects fast.

5‑axis machining allows the cutter to approach the workpiece from many directions. As a result, it shapes complex parts in a single setup with high accuracy and less waste. That adds efficiency and quality quickly.

In traditional 3‑axis machining, the cutter moves along X, Y, and Z axes. That works for fairly simple shapes. However, if the design has features at odd angles, deep pockets, undercuts, or contoured surfaces, 3‑axis often fails. Engineers then need multiple setups, manual re‑clamping, or even hand finishing. Each extra setup adds risk. Misalignment between setups can cause poor tolerances. Extra handling also increases time and cost.

With 5‑axis CNC, tool or table tilts along two extra rotary axes (often labeled A and B or B and C). This lets the tool reach tricky surfaces with correct cutting angles. Machining happens in one setup. That reduces error from repositioning. That boosts repeatability. That saves time and reduces labor.

Key advantages

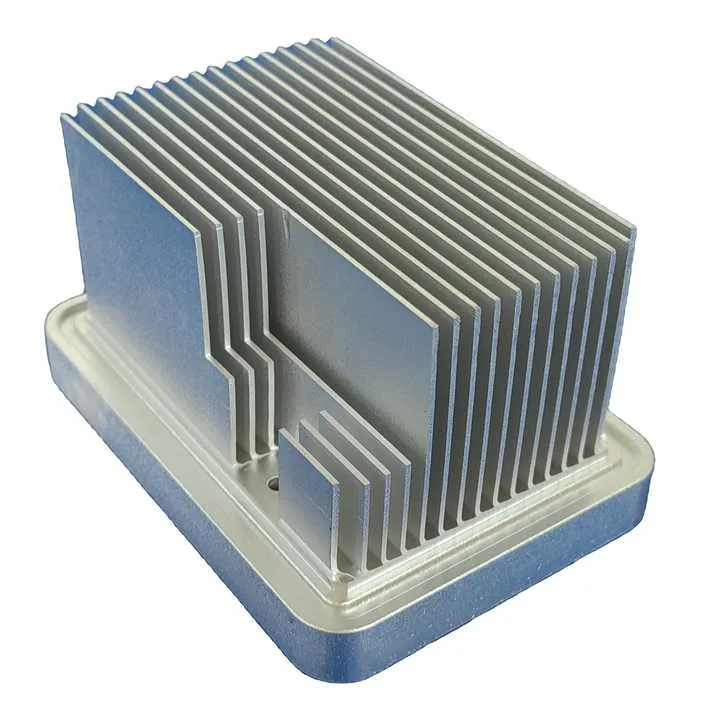

- Better surface finish: Cutter can stay perpendicular to surface across curves. That avoids chatter or poor contact.

- Shorter tools possible: Because tool touches the workpiece from ideal angle, there is less overhang. Shorter tools deflect less. That improves precision.

- Fewer setups: Complex parts often complete in one go. That lowers labor. That reduces risk.

- Time efficiency: Single‑setup means faster lead time. Especially for high volume, the savings multiply.

Comparison: 3‑axis vs 5‑axis

| Feature / Requirement | 3‑Axis CNC | 5‑Axis CNC |

|---|---|---|

| Number of axes | 3 (X, Y, Z) | 5 (X, Y, Z, plus A & B) |

| Ability to reach angled surfaces | Limited, may need multiple setups | High, in one setup |

| Tool length requirement | May need long overhang | Often shorter, more stable |

| Accuracy for complex shapes | Lower, higher error risk | Higher, consistent accuracy |

| Setup count | Multiple for complex parts | Usually one |

5-axis CNC gives designers and manufacturers freedom. Shapes that were once costly, slow, or hard to produce are now easier to machine. That changes how people approach product development and engineering.

Why do aerospace parts require 5-axis technology?

Aerospace parts often have intricate shapes. They also demand tight tolerances. That makes them hard to produce using simpler machines. That problem can delay production or raise cost.

Aerospace parts require 5‑axis CNC because many components have complex curves, compound angles, and tight precision needs. 5‑axis delivers the geometry and accuracy in fewer setups. That ensures quality and consistency vital for flight safety and performance.

In aviation or spacecraft, components often have curved surfaces, twisted profiles, or internal pockets. Wing ribs, turbine blades, structural frames, and many other parts need precise shaping. Designers expect exact tolerances. Also parts must meet strict regulatory standards. In many cases, even tiny misalignment can cause big trouble.

Using 3‑axis CNC for these parts often means many setups, manual repositioning, and manual finishing. That raises chances of error. Also manual steps may produce inconsistent surfaces or stress points. For critical aerospace parts, that is unacceptable.

With 5‑axis CNC, manufacturers can machine complex shapes in one go. That lowers chance of error. That keeps tight tolerances across all surfaces. That yields uniform part quality batch after batch.

Value for aerospace manufacturing

- Reduced assembly error: Parts that fit together precisely, reducing need for rework.

- Improved part strength: No need for welding or manual finishing that can introduce weak spots.

- Weight control: Many aerospace parts rely on light alloys. 5‑axis allows material removal while keeping structural integrity.

- Cost and time savings: Fewer setups, less labor. Faster turnaround. Better for tight production schedules.

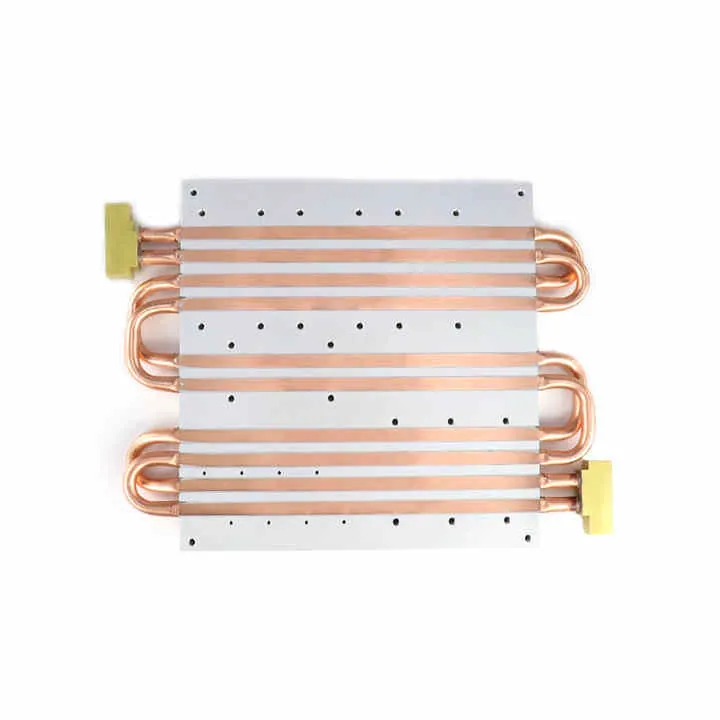

Often, aerospace parts also use materials like aluminum alloys or titanium. Those metals can be hard to machine. 5‑axis tooling can adapt cutting angles to reduce wear and heat. That preserves material integrity.

In short, aerospace demands complexity, precision, and strict quality. 5‑axis CNC meets those demands. That makes 5‑axis nearly mandatory in modern aerospace manufacturing.

Which geometries benefit most from 5-axis CNC?

Not all parts need full 5‑axis flexibility. Some shapes remain simple enough for 3‑axis machining. However some geometries clearly benefit from 5‑axis.

Geometries with angled features, deep cavities, undercuts, complex curves, or multi‑sided profiles benefit most. In these cases 5‑axis CNC offers better access, accuracy, and efficiency.

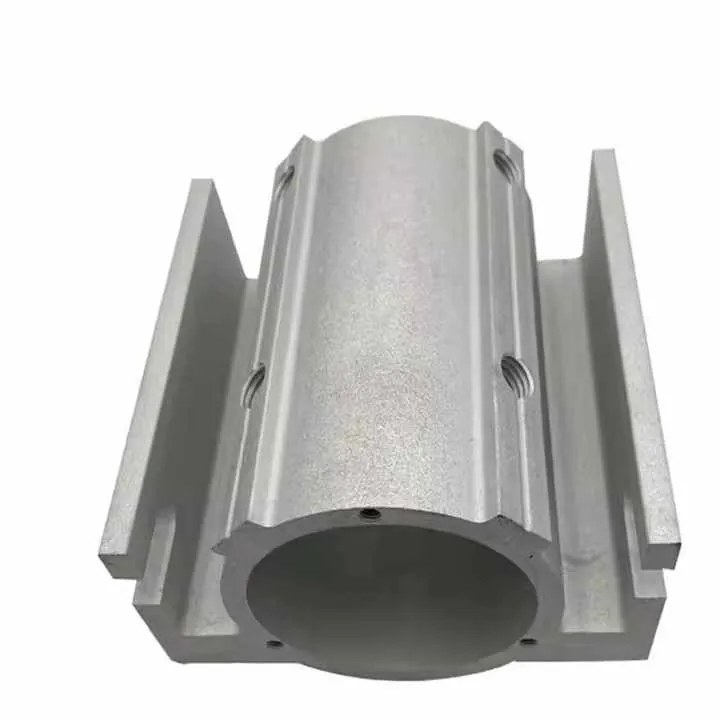

Parts that include features like angled holes, sloped faces, internal cavities, curved surfaces, multi‑plane cuts or twisted shapes are ideal for 5‑axis. For example:

- Surfaces that curve in two directions (double curvature)

- Undercuts where the cutter must approach from below or a side angle

- Deep pockets with narrow entry

- Holes or slots that are angled relative to main axes

- Multi‑surface parts needing machining from different orientations

Typical geometry types that benefit

| Geometry Characteristic | Benefit from 5‑Axis CNC |

|---|---|

| Curved surfaces (double curvature) | Smooth finish, no need for manual polishing |

| Tilted or angled faces | Accurate cutting without re‑setup or manual tilting |

| Internal cavities or deep pockets | Better tool access, avoids collisions |

| Multi‑sided bodies | Machined in one setup, fewer clamps |

| Twisted or complex profiles | Accurate shaping, better fit in assemblies |

For those shapes, 5‑axis CNC allows the tool to meet the surface at ideal angle. That keeps cutting efficient. That reduces chatter or tool stress. That improves surface finish.

Often modern designs aim to reduce weight while maintaining strength. They use curved or hollow shapes. 5‑axis can cut thin walls, hollow sections, or complex ribs in one go. That helps realize lightweight yet strong parts.

Also in industries like medical, automotive, or energy, where parts require ergonomic shapes or fluid flow optimization, those curved or contoured surfaces matter. 5‑axis can deliver smooth surfaces that improve performance or reduce drag.

Thus when parts include complex geometry — above categories — choosing 5‑axis CNC brings clear benefits. It reduces production time, improves precision, and reduces post‑machining work.

What skills are needed to program 5-axis machines?

Operating 5‑axis CNC is more demanding than simple 3‑axis. Operators need knowledge of tool paths, machine geometry, collision avoidance, tool orientation, and workholding. Without care, mistakes cause scrap or damage.

Key skills include CAD/CAM programming, spatial thinking for 5‑axis tool paths, understanding of machine kinematics, careful setup and workholding, plus knowledge of materials and cutting parameters. These skills enable safe, accurate, efficient machining.

Working with 5‑axis CNC often begins with CAD design. Programmer must create or import 3D model. Then they define tool paths that cover all surfaces. They must choose tool sizes and orientations. They must ensure no collision occurs between tool, part, or machine. They must plan proper workholding to keep part stable across all movements.

Essential skill categories

| Skill Area | What It Covers |

|---|---|

| CAD / CAM competence | Creating models, generating tool paths, exporting to machine code |

| Spatial reasoning | Visualizing cutter movement, tool‑part‑machine interactions |

| Machine kinematics | Understanding rotary axes, tool orientation, axis limits |

| Workholding & fixturing | Designing fixtures that hold part securely through movement |

| Material knowledge | Knowing how material behaves, choosing speeds and feeds |

Beyond that, operator must monitor machine closely during first runs. They must watch for collisions, errors, or unexpected behavior. They should test on cheaper material first. Then refine settings before final run.

Also communication with design or engineering team matters. If part design is complex, programmer might suggest design tweaks or machining-friendly changes. That can simplify manufacturing.

In many shops, programming for 5‑axis requires training or experience. Novices often begin on simpler 3‑axis jobs and graduate to 5‑axis once they master basics. Good practices include using simulation software to preview motion before cutting. Also documenting tool paths, workholding methods, and lessons learned for future jobs.

Finally, being proactive helps. Checking tool wear, machine calibration, fixture alignment regularly prevents mistakes. Attention to detail makes difference between a good part and scrap.

Conclusion

5‑axis CNC expands what is possible in metal machining. It handles complex shapes, su