5-axis CNC machining is a cutting-edge manufacturing process that allows for high precision and complex part production. Using five axes of motion, this system can produce intricate designs with incredible accuracy, significantly enhancing the capabilities of traditional machining.

5-axis CNC machining involves a machine tool that moves a part or tool in five different directions, allowing for more complex shapes and angles to be cut in a single setup. Unlike traditional 3-axis machines, which can only move along X, Y, and Z axes, 5-axis machines also rotate the tool or workpiece along additional rotational axes. This versatility makes 5-axis machining indispensable for industries that require highly detailed and intricate components. In this article, we’ll explore how 5-axis machining improves accuracy, why manufacturers adopt it, which parts benefit most from it, and where it's used today.

The introduction of 5-axis CNC machining has transformed manufacturing, offering more versatility and higher precision. Let's take a closer look at the key aspects that make 5-axis machining such a game-changer in the industry.

How Does 5-Axis Machining Improve Accuracy?

5-axis CNC machining allows for complex movements and cuts that are simply not possible with traditional 3-axis machines. By using five axes of motion—three linear and two rotational—this system can reach nearly any angle, ensuring greater accuracy when cutting intricate shapes or working with complex geometries.

Key Benefits for Accuracy:

- Multi-directional Cutting: With five axes, the tool can approach the workpiece from virtually any direction, minimizing the need for multiple setups.

- Reduced Error: Fewer tool changes and setups reduce the risk of error that could arise from manual adjustments or re-positioning.

- Higher Precision: The ability to manipulate the tool in more ways means parts can be cut more precisely, with smoother surfaces and tighter tolerances.

In traditional 3-axis machining, the part or tool may need to be repositioned multiple times to complete the cutting, leading to alignment issues or errors. With 5-axis machining, the machine can perform more cuts in one continuous operation, ensuring the part is exactly as designed.

Why Do Manufacturers Adopt 5-Axis Systems?

Adopting a 5-axis CNC machine offers manufacturers numerous advantages, particularly in industries where precision and efficiency are key. These systems allow for faster production, more complex designs, and reduced setup times, making them invaluable for modern manufacturing.

Reasons Manufacturers Choose 5-Axis Systems:

- Increased Efficiency: With fewer setups and tool changes, production time is greatly reduced.

- Complex Parts: 5-axis machining can handle intricate designs that would be difficult or impossible with 3-axis machines.

- Cost Savings: While the initial investment is higher, the long-term savings come from faster production and reduced error rates.

- Improved Surface Finish: The increased accuracy of 5-axis machining results in a smoother surface finish, reducing the need for post-processing.

Manufacturers who need high precision and efficiency in their production processes are increasingly turning to 5-axis systems. Whether for reducing lead times or improving the quality of finished parts, the benefits of 5-axis CNC machining make it a popular choice.

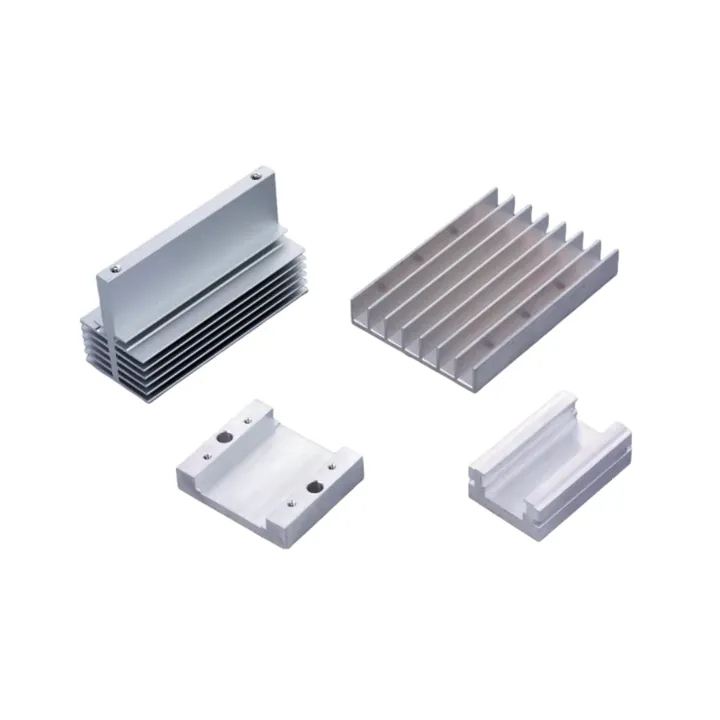

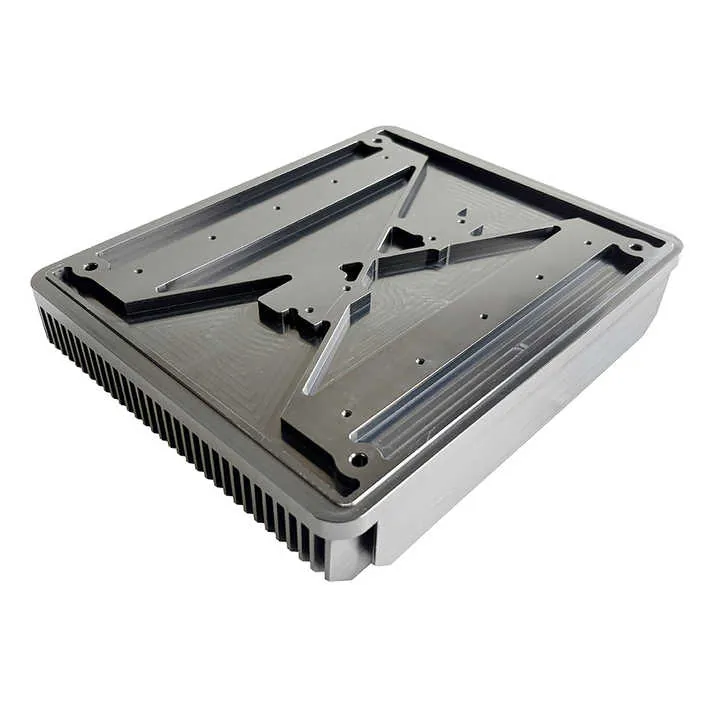

Which Parts Require 5-Axis Machining?

5-axis machining is particularly useful for manufacturing parts that require complex geometries, tight tolerances, or high levels of detail. This technology is ideal for components with features that are difficult to access or that require multiple angles of cutting.

Parts That Benefit from 5-Axis Machining:

| Part Type | Example | Why It Needs 5-Axis Machining |

|---|---|---|

| Aerospace | Aircraft parts, turbine blades | Complex shapes, lightweight materials |

| Medical | Surgical instruments, implants | High precision and complex surfaces |

| Automotive | Engine components, gears | Intricate details, tight tolerances |

| Energy | Turbine parts, compressor blades | High complexity, multi-directional cuts |

These parts often require several complex angles and intricate details that are beyond the capabilities of 3-axis machines. For example, aerospace turbine blades have curved, twisted surfaces that must be cut from multiple angles to ensure the part functions properly.

Where is 5-Axis Machining Used Today?

5-axis CNC machining is now widely used across various industries, particularly in fields where precision and complexity are paramount. From producing aerospace components to medical devices, 5-axis machining is essential for creating parts that require the highest levels of accuracy.

Key Industries Using 5-Axis Machining:

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Aircraft parts, engine components | High precision, lightweight designs |

| Medical | Surgical instruments, implants | Exacting tolerances, complex shapes |

| Automotive | Engine blocks, transmission components | Complex geometries, tight tolerances |

| Energy | Turbine blades, power generation components | High complexity, durability |

The aerospace industry is one of the largest users of 5-axis machining, as aircraft parts often require complex, three-dimensional shapes that must be manufactured with extreme precision. Similarly, the medical industry relies on 5-axis machines to produce intricate surgical instruments and implants, where even the smallest deviation could result in failure.

Conclusion

In conclusion, 5-axis CNC machining offers a major leap in precision and efficiency for manufacturers. It enables the production of complex parts with high accuracy, reduces the number of setups, and improves overall production speed. Whether in aerospace, automotive, or medical manufacturing, 5-axis machining is becoming an essential tool for industries that require the utmost precision in their products.