A lot of people are confused when they hear “3-axis CNC machine.” It sounds technical. But once we break it down, it’s actually simple to understand and useful to know.

A 3-axis CNC machine is a computer-controlled tool that moves a cutting head in three directions—X, Y, and Z—to shape a part or surface.

This technology forms the foundation of many manufacturing processes today. From automotive components to aluminum frames, it plays a huge role in shaping modern industry. Let's look at how it works and why it matters.

How does 3-axis motion work?

A common question is: what exactly are these three axes? Why do they matter in machining?

3-axis motion means the tool can move left-right (X), forward-backward (Y), and up-down (Z) to cut, drill, or shape the material.

In a basic 3-axis CNC system, the cutting tool stays aligned in the same direction as it moves. The part stays still while the tool does all the moving. Think of it like using a knife to slice a block of butter while your hand moves side to side, back and forth, and up and down—but you never tilt your hand.

This kind of movement is perfect for flat surfaces or shapes that don’t need too many angles. It makes the machine design simpler and the operation more stable. That’s why many manufacturers rely on it for large production runs of straightforward parts.

Key Axes of Movement

| Axis | Direction | Motion Type |

|---|---|---|

| X | Left ↔ Right | Linear horizontal |

| Y | Front ↔ Back | Linear depth |

| Z | Up ↕ Down | Vertical movement |

This structure allows the machine to perform tasks like:

- Milling surface areas

- Drilling vertically

- Cutting flat plates

The machine's motion is managed through a CAM (Computer-Aided Manufacturing) system, which takes CAD (Computer-Aided Design) files and translates them into paths for the tool to follow.

Limitations of 3-Axis Machines

- No tilting or rotation of tools

- Less effective for undercuts or angled holes

- Struggles with complex 3D contours

But despite those limits, the reliability and lower cost of 3-axis systems make them a practical choice for a huge range of applications.

Why choose 3-axis machining?

Many businesses want to know if 3-axis CNC is enough—or if they should go with more advanced systems.

3-axis machining is the most cost-effective and reliable choice for producing flat or moderately complex parts in large quantities.

One of the biggest advantages is simplicity. A 3-axis machine is easier to program, operate, and maintain compared to a 4-axis or 5-axis system. The learning curve is shorter, so operators can reach efficiency faster.

Benefits of 3-Axis Systems

| Benefit | Description |

|---|---|

| Lower cost | Machines and maintenance are more affordable than multi-axis systems |

| High speed | Ideal for high-volume production runs |

| Easy operation | Simpler to program and run, especially for basic geometries |

| Stable quality | Less vibration and fewer mechanical variables improve consistency |

For many industries, 3-axis machining strikes the right balance between price and performance. If the part doesn’t require tilting or rotating the tool, then there’s no reason to overpay for added complexity.

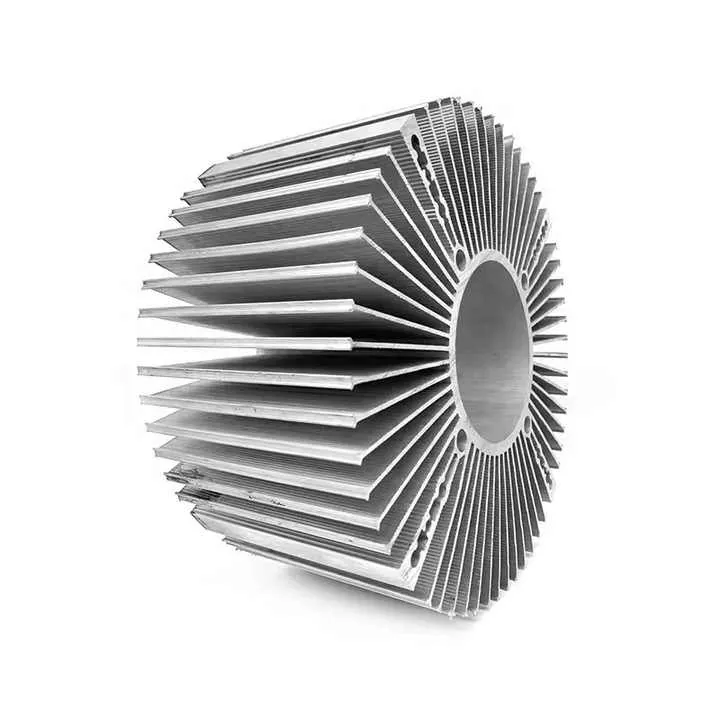

Use Case Story

One of our clients in the lighting industry needed thousands of aluminum heatsinks with precise flat surfaces. We used a 3-axis CNC setup to achieve high surface finish quality, fast turnaround, and reliable tolerances. The result: their production costs went down, and product quality stayed high.

Which parts fit 3-axis systems?

It’s not always obvious which types of parts are suitable for 3-axis machining.

3-axis CNC is best for parts with flat surfaces, simple geometries, or shallow cavities that don’t require angled features.

If a part can be completed without needing to rotate or tilt the tool, it probably fits 3-axis machining. This includes things like mounting plates, housings, basic frames, and panels.

Examples of Compatible Parts

Common Parts

- Brackets

- Flat frames

- Light fixtures

- Electronic enclosures

Automotive

- Dashboard panels

- Gearbox plates

- Flat engine components

Construction

- Curtain wall profiles

- Window frames

- Solar panel rails

When choosing 3-axis CNC, the key factor is visibility. If the cutting tool can reach all the surfaces without obstruction, then the part is suitable. But if it has deep pockets or angled undercuts, you might need more advanced machining.

When to Upgrade

Here’s a simple rule: If your part needs more than one setup or fixture to access all features, then a multi-axis system may save time in the long run.

Where are 3-axis machines used?

Some people assume 3-axis CNC is only for small workshops or basic projects. That’s not true.

3-axis CNC machines are used in industries like aerospace, automotive, electronics, and construction for efficient part production.

Their affordability and simplicity make them ideal for many tasks, especially those involving repetitive production. Even in high-tech sectors, many secondary or supporting components are still made on 3-axis systems.

Industry Applications

Aerospace

- Interior cabin panels

- Simple brackets

- Electronic housings

Automotive

- Flat aluminum structural parts

- Engine covers

- Transmission plates

Electronics

- Heat sinks

- Device frames

- Mounting bases

Construction

- Architectural aluminum profiles

- Solar panel supports

- Structural components

In our experience, we’ve supported projects ranging from LED light casings to solar frame rails using only 3-axis CNC. In many cases, clients are surprised by how much can be achieved with just three axes—especially when matched with strong programming and quality materials.

Conclusion

3-axis CNC machines offer a perfect mix of cost-efficiency, ease of use, and reliability. For many applications, especially flat or simple shapes, this system is more than enough to get the job done.