Today’s precision manufacturing needs go beyond simple shapes. As part geometry becomes more complex, older 3 or 5-axis systems just can’t keep up.

A 7-axis CNC machine is a computer-controlled manufacturing tool that can move a part or tool in seven different directions for unmatched precision and flexibility.

This technology is changing how we approach high-precision tasks. Whether it’s aerospace, automotive, or medical, more manufacturers are turning to this multi-axis system to make complex parts in fewer steps and with tighter tolerances.

How does a 7-axis machine move?

A basic CNC machine moves in three directions: X (left-right), Y (forward-backward), and Z (up-down). This is enough for flat parts or simple cuts. But many products today aren’t flat or simple. That’s where more axes come in.

A 7-axis CNC machine can move in X, Y, Z, plus rotate on three different axes (A, B, and C), and also includes a seventh axis—usually a linear extension or rotary movement in the tooling system.

A 7-axis machine usually works with a robotic arm or a moving spindle. This seventh axis lets it perform advanced tasks like deep hole drilling at complex angles, or multi-side machining in a single setup. This reduces repositioning time and increases consistency.

The Seven Axes Explained

| Axis | Type of Movement | Description |

|---|---|---|

| X | Linear (left-right) | Moves part or tool left and right |

| Y | Linear (front-back) | Moves part or tool forward and backward |

| Z | Linear (up-down) | Moves part or tool vertically |

| A | Rotational (around X-axis) | Rotates the part/tool side to side |

| B | Rotational (around Y-axis) | Tilts the part/tool forward and backward |

| C | Rotational (around Z-axis) | Spins the part/tool like a turntable |

| E (or 7th) | Extra linear or rotary | Often used for arm extension or turret spin |

This full range of movement allows for uninterrupted cutting, fewer re-clamps, and more reliable machining. It also minimizes human error. Operators don’t need to stop and reposition the material manually.

Another advantage is that the 7-axis machine can keep the cutting tool at the optimal angle at all times. This extends tool life and gives better surface finishes.

Why choose 7-axis for complex parts?

Machining complex parts on a 3-axis system can be time-consuming. It often requires multiple setups, which can lead to misalignment and errors.

With 7-axis CNC, you can machine complex parts in one setup, improving precision and reducing overall production time.

When a part has curves, undercuts, or angled holes, it can’t be done in one go on a basic CNC. A 7-axis machine can handle these in a single cycle. It moves and adjusts the part or tool in real-time, maintaining the exact orientation needed.

Comparison of CNC Axis Systems

| Features | 3-Axis CNC | 5-Axis CNC | 7-Axis CNC |

|---|---|---|---|

| Movement Complexity | Basic | Moderate | Very Advanced |

| Tool Access | Limited | Better | Full access at all angles |

| Setups Required | Multiple | Few | Usually one |

| Surface Finish | Standard | Good | Excellent |

| Production Time | Longer | Medium | Shortest |

| Suitable for Complex Geometry | No | Partially | Yes |

One big reason why manufacturers switch to 7-axis is the part geometry. In industries like aerospace or medical implants, parts often have curved surfaces or deep cavities. These features are hard to reach with traditional tools.

This also helps when the production volume is low, but the quality needs are high. With 7-axis CNC, you get consistency, even for short production runs.

The machine’s ability to reach hard angles also means fewer fixtures are needed. This cuts down tooling costs and makes the production process more flexible.

Which industries use 7-axis systems?

Not every shop needs a 7-axis CNC. But in industries where quality, speed, and geometry matter, this technology can be a game changer.

Industries like aerospace, automotive, medical devices, and robotics rely heavily on 7-axis machines for their most complex parts.

These industries work with tough materials and tight specs. The 7-axis system helps meet those requirements without sacrificing efficiency.

Key Industries Using 7-Axis CNC

Aerospace

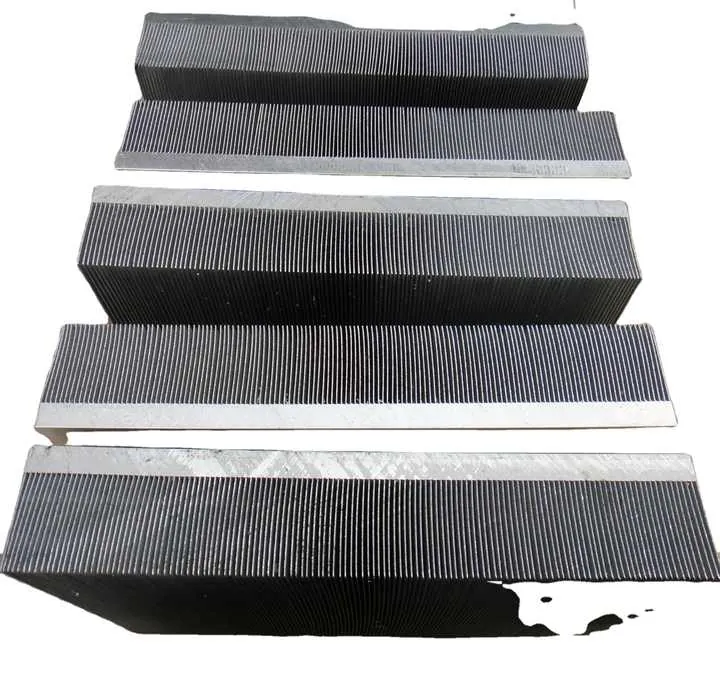

Airplane parts often have complex shapes for aerodynamic efficiency. A 7-axis machine can mill these parts with extreme precision. It also helps reduce part weight by cutting more efficiently, using fewer joints.

Medical Devices

Implants and surgical tools need complex shapes and ultra-fine finishes. 7-axis systems help produce spine implants, hip joints, and custom surgical instruments, all in one go.

Automotive

High-performance car parts like engine blocks or suspension parts need fine details and tight tolerances. The extra axes allow for simultaneous multi-angle machining, perfect for parts that must fit together seamlessly.

Robotics

Robot components often involve intricate cuts and internal paths. The flexibility of a 7-axis machine is ideal for making robotic joints, gears, and complex frames.

Defense and Energy

In defense, parts must meet military-grade specs. For energy sectors like wind or oil, parts can be huge and geometrically complex. A 7-axis CNC can machine these large parts in fewer steps, keeping everything aligned.

The ability to machine advanced materials—like titanium, Inconel, or hardened steels—also makes 7-axis a perfect fit for these sectors.

Where do 7-axis machines perform best?

Adding more axes sounds great, but not every factory can justify the cost. These machines shine in high-precision, high-value, low-volume environments.

7-axis CNC machines perform best in shops that need complex, multi-surface parts with tight tolerances, minimal setups, and high repeatability.

Let’s look at when it makes the most sense to use this advanced technology.

Best Use Cases for 7-Axis CNC

Prototyping High-End Parts

For R&D teams or custom manufacturing, 7-axis is great for prototyping. It allows multiple iterations without setting up new jigs or fixtures. This helps bring products to market faster.

Short-Run, High-Mix Production

In industries like medical or defense, one part may be very different from the next. 7-axis allows a fast changeover and fewer tooling adjustments. That keeps the cost and time under control.

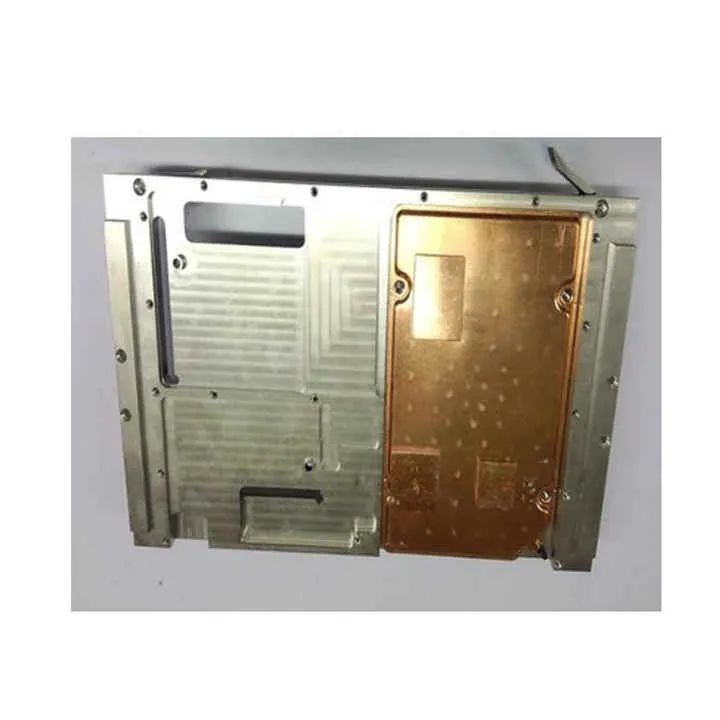

Complex Mold Making

Molds need deep cavities and undercuts. These features are hard to reach with fewer axes. A 7-axis machine can cut inside molds at angles that standard machines can’t reach.

Tight Tolerances

Some parts require tolerances within microns. Every repositioning increases the risk of error. With 7-axis machining, the part stays in place. The tool moves around it, keeping everything aligned.

Advanced Material Handling

Some metals are difficult to cut. Titanium, for example, wears tools quickly and needs optimal angles. The 7-axis system adjusts the cutting position live to protect the tool and maintain surface finish.

Conclusion

7-axis CNC machines offer unmatched flexibility and precision for the most complex parts. They reduce setups, save time, and meet the toughest industry demands.