I remember the time I saw a raw metal sheet transform into a delicate pattern in minutes. That sudden change felt like magic — until I learned it was all thanks to CNC cutting.

A CNC cut uses computer‑controlled machines to guide cutting tools with high accuracy. It turns digital designs into real parts with minimal waste and reliable repeatability.

This article explains how CNC cutting works, why it shines for complex shapes, what materials it handles, and where people use it most. Keep reading to see if CNC cutting fits your needs.

How does CNC cutting achieve precision?

The moment CNC starts, you know precision will follow. Tiny errors simply can’t hide.

CNC cutting stays precise because software drives exact tool motions, and machines repeat the moves the same way each time.

When I think about CNC precision, I think about how a recipe works: you follow exact steps, and you get the same result each time. With CNC cutting, a digital design file — usually CAD (computer‑aided design) — feeds instructions to the machine. That file defines every line, curve, depth, or angle of the cut. Then a computer translates those instructions into tool movements: linear paths, arcs, circles, plunges. The machine’s controller moves the tool or the workpiece along X, Y (and sometimes Z) axes in small incremental steps. Because the controller knows exactly where the tool should be at every moment, the resulting cut follows the design with minimal deviation.

The hardware also matters. CNC machines often use stepper motors or servo motors. Servo motors feed back actual position data to the controller, ensuring the tool stays on the planned path. If the tool drifts a bit due to force or vibration, the controller corrects it. The machine’s structural rigidity — the frame, guides, spindle mount — reduces flex and wobble. That rigidity helps prevent small errors from accumulating. Also, many CNC cutters use high‑quality spindles or laser heads, giving stable and consistent cutting power. That consistency avoids irregularities.

Repeatability is often as important as one‑off precision. Once a CNC program runs, it can repeat the same cut hundreds of times and yield almost identical parts. That is critical for industries where parts must match tight tolerances across batches.

The precision level depends on machine quality, tool sharpness, design complexity, and material. But even entry‑level CNC machines often hold tolerances within a few thousandths of an inch or hundredths of a millimeter. High‑end industrial CNC centers can do even tighter tolerances. For many applications — machine parts, electronics enclosures, structural components — that level of precision is good enough or better than manual methods.

Thus CNC cutting achieves precision by combining exact digital instructions, controlled tool movement, feedback mechanisms, rigid hardware, and consistent cutting environment. The result is high accuracy and repeatable quality that manual cutting methods can rarely match.

Why is CNC cutting ideal for intricate designs?

Complex shapes often scare off manual cutters. CNC does not care. It follows curves, holes, pockets the same as straight cuts.

CNC cutting handles intricate designs easily because the computer drives the tool exactly along complex paths. That makes detailed patterns or fine features possible.

I once saw a sheet of wood being carved into a lace‑like pattern. Every swirl and small notch came out sharp and clean. Manual cutting would take too long and risk errors. CNC made it fast and precise. The machine read a design with sine waves, fillets, inner voids, thin walls, and repeated it without hesitation.

The heart of this ability lies in the digital design and motion control. A CAD file can hold any geometry: curves, arcs, holes, internal cutouts, nested shapes — simple or very complex. When that file goes to the CNC controller, the machine plans a toolpath that respects all these geometric details. The toolpath may include rapid moves, careful slow passes, or different cutter shapes. If the design calls for a small round hole inside a tight area, the machine can approach it with a small tool bit and carve precisely. If the design includes thin bridges or narrow walls, the CNC can mill along those walls without undue stress or error, because the machine controls the force, feed rate, and spindle speed.

Another advantage is consistency. Once you have the design and the right setup — correct tool, speeds, feeds, hold-downs — you can produce many identical parts with recurring patterns. That matters for things like decorative panels, customized enclosures, parts for complex machinery, signage, or aesthetic components. Intricate shapes that used to need handcrafted labor or complex molds can now be cut directly from raw material with far less effort and shorter lead time.

Also, CNC design modifications are easy. If you want to change a curve, adjust a hole position, or tweak a pattern, you edit the CAD file once. Then every subsequent part reflects the change. That agility makes CNC ideal for prototyping, product customization, and small-batch runs where complex shapes vary often.

In sum, CNC cutting is ideal for intricate designs because digital paths guide the tool with high control, the hardware handles fine motion and forces, and the workflow supports both detail and repeatability. For any project that demands exact geometry, delicate features, or consistent repeats, CNC gives a clear advantage over manual cutting.

Which materials are suitable for CNC cutting?

The choice of material matters. Hard metal and soft wood are both possible. CNC adapts.

CNC cutting works with metals, plastics, wood, composites and more. Suitability depends on machine type, tool, and cutting method.

The range of materials that CNC cutting can handle is broad. Many metals are common: aluminum, steel, stainless steel, brass, copper, titanium. Soft metals like aluminum cut quite easily. Harder metals like steel need strong spindles, rigid machines, and proper tooling, but CNC handles them. Non‑metals also work well: wood, plywood, MDF, acrylic, plastics like ABS or polycarbonate, foam, composites like carbon fiber panels or fiberglass, and even materials like wax or foam for prototyping.

Here is a simple table showing common materials and their suitability for CNC cutting:

| Material Type | Ease of CNC Cutting | Typical Uses |

|---|---|---|

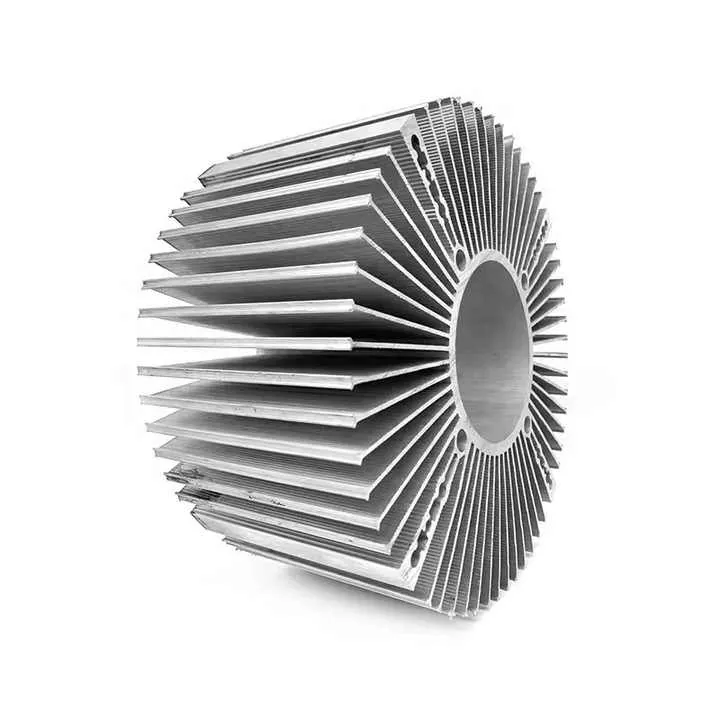

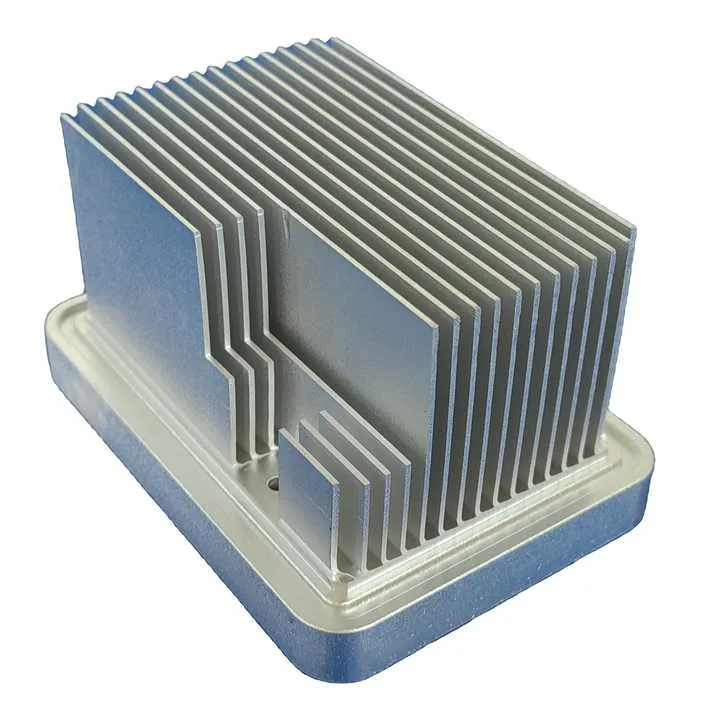

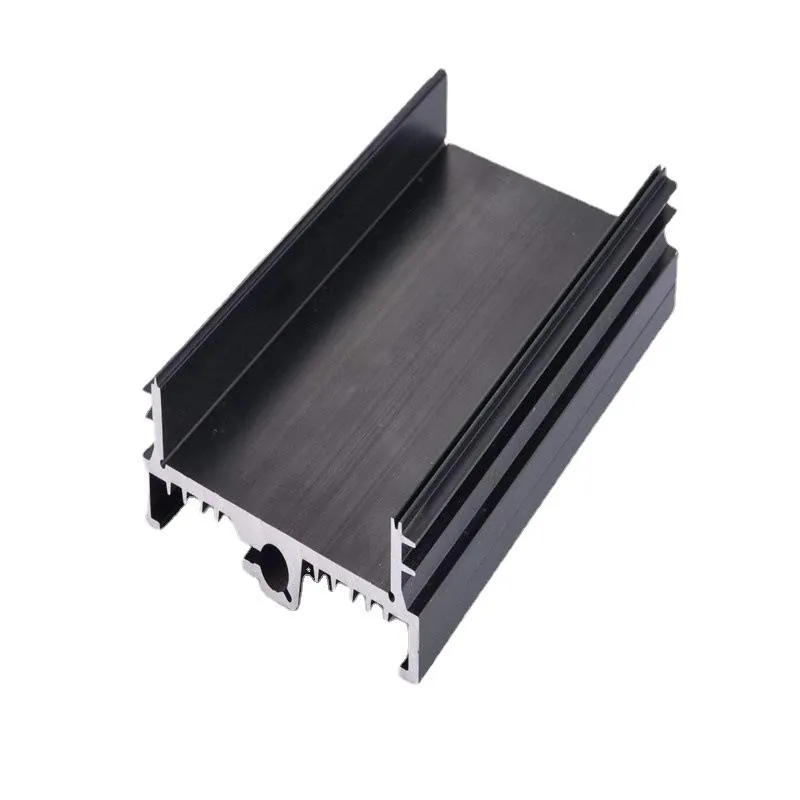

| Aluminum | Easy | Enclosures, frames, panels, heat sinks |

| Steel / Stainless Steel | Medium to Hard | Structural parts, brackets, tooling |

| Brass / Copper | Medium | Decorative parts, electrical contacts |

| Plastics (ABS, Acrylic) | Easy | Housings, prototypes, signage |

| Wood / MDF | Easy | Furniture, decorative panels, signage |

| Composite (Carbon Fiber, Fiberglass) | Medium | Lightweight structural parts, housings |

| Foam / Wax | Very Easy | Prototypes, molds, packaging inserts |

You pick material based on desired part strength, finish, weight, and cost. CNC lets you handle many materials with the same machine — sometimes just by changing the tool bit and speeds.

Some materials require special care. For example, cutting steel demands coolant or lubricant to control heat and avoid tool wear. Composites like carbon fiber dust require dust control and safety gear. Soft materials like wood may cause tear‑out or chipping if cutter and feed are not right. That means machine setup matters: tool type (end mill, router, laser), feed rate, spindle speed, coolant or dust removal.

CNC cutting also supports layered materials — e.g., sandwich panels, laminated sheets, plastics with coatings. That is useful for complex builds or composite parts. The machine can cut through layers cleanly, ensuring edges stay sharp and stacking is accurate.

In short, CNC cutting suits many materials. From soft wood to hard steel, from plastics to composites, CNC is flexible. The limiting factor is often the machine capability and how well the operator sets up cutting parameters, not the material itself.

Where is CNC cutting used?

CNC cutting appears in workshops, factories, and labs everywhere. Its use spans many industries and needs.

CNC cutting is used in manufacturing, design prototyping, construction, signage, furniture, aerospace, and more — any field needing precise parts or complex shapes.

Whenever a design needs precision, repeatability, or complex shape, CNC cutting can help. In manufacturing, CNC machines cut metal parts for machinery, frames, enclosures, brackets, and structural components. In electronics, CNC makes housings, panels, and heat‑sink parts. Plastic prototypes for new products often go through CNC routing before mass production via injection molding. That speeds up design cycles and allows fast testing.

In furniture and cabinetry, CNC routers carve wood or MDF into panels, joinery parts, decorative trims, or complex shapes for modern designs. Sign makers use CNC to carve logos, lettering, or decorative signage from wood, plastics, or metals. Artistic and design studios carve sculptures, decorative panels, custom fixtures, or props. CNC helps make these without months of manual carving.

CNC also shows up in aerospace and automotive industries. Light‑weight metal parts, structural brackets, custom mounts, and fixtures often come from CNC machining. Prototypes and parts for aerospace systems need tight tolerances and reliable materials; CNC fits those needs. Even medical equipment manufacturers use CNC to cut metal or plastic parts for housings, frames, or internal components.

Construction industries use CNC in building custom metal or wood elements — like architectural metal panels, decorative façades, frames, metal enclosures, or structural supports. Composite material cutting — e.g., carbon fiber panels for drones, e‑bikes, or enclosures — often relies on CNC.

Below is a table summarizing common application areas and typical CNC‑cut parts:

| Industry / Field | Typical Parts / Products |

|---|---|

| Manufacturing | Machine parts, frames, brackets, enclosures |

| Electronics / Tech | Housings, panels, heat sinks, chassis |

| Furniture / Woodwork | Cabinets, decorative panels, joinery, trims |

| Signage & Advertising | Signs, logos, decorative lettering |

| Automotive / Aerospace | Structural brackets, mounts, prototypes |

| Medical Devices | Equipment housings, structural parts, prototypes |

| Art & Design | Sculptures, decorative fixtures, custom pieces |

| Construction | Architectural panels, metal frames, façade elements |

Because CNC works with many materials, it adapts to many industries. One machine can support several disciplines just by changing tools and parameters. That flexibility often reduces cost and lead time compared to specialized equipment or manual methods. It suits both low volume custom jobs and high volume repeats. That makes CNC cutting a very versatile tool.

Conclusion

CNC cutting transforms digital designs into real parts with precision, flexibility, and speed. It works for many materials, supports complex shapes, and fits wide uses. For anyone who values accuracy, repeatability, and design freedom, CNC cutting stands out as a strong choice.