Cutting metal used to be slow and rough. Now, it’s fast and razor-sharp—thanks to CNC laser cutters. If you're in manufacturing or design, this tool is changing how things are made.

A CNC laser cutter is a computer-controlled machine that uses a focused laser beam to cut or engrave materials with high precision, speed, and minimal material waste.

Laser cutting isn’t just about speed—it’s about perfect edges, complex shapes, and repeatable quality. Let's explore how this technology works and why it's so widely used across industries.

How does a CNC laser cutter work?

Traditional cutting tools struggle with precision and often wear out quickly. Lasers solve both problems by using light, not force.

CNC laser cutters operate by focusing a high-energy laser beam onto a material surface, melting or vaporizing it to create precise cuts, all guided by computer control.

A laser cutter uses a powerful beam of light generated by a laser source. This beam travels through mirrors and lenses, narrowing it into a focused spot. When this beam hits a material, the energy is intense enough to melt, burn, or vaporize it instantly.

Basic Process Flow:

- Design Creation – Made using CAD or vector software

- File Upload – Design is sent to the CNC controller

- Laser Activation – Beam is focused onto the material

- Movement Control – Machine follows design path precisely

- Cut Completion – Parts fall away with smooth, clean edges

Key Parts of a CNC Laser Cutter:

| Component | Function |

|---|---|

| Laser Source | Generates the laser beam |

| Optics & Lenses | Focuses the beam into a sharp, intense point |

| CNC Controller | Moves the laser head based on CAD data |

| Work Table | Holds material securely |

| Assist Gas System | Blows away molten material and cools the cut |

Different types of laser sources include:

- CO₂ lasers – Best for non-metals like wood, plastic, and acrylic

- Fiber lasers – Ideal for metals like steel, aluminum, and brass

- Nd:YAG lasers – Suitable for high-precision cuts in harder materials

With tight beam control, the laser can produce very thin kerf widths—sometimes less than 0.1 mm. This allows for detailed work, like engraving serial numbers or cutting complex gears.

Why choose laser cutting for precision?

Manufacturing is moving fast. Mistakes cost time and money. That’s where CNC laser cutting makes a difference.

Laser cutting is chosen for its unmatched accuracy, clean edges, minimal distortion, and the ability to produce intricate designs on a wide range of materials.

Unlike mechanical cutting, laser cutting doesn't touch the material. No contact means less vibration, less force, and no physical wear. This produces better edges and more precise dimensions.

Advantages of CNC Laser Cutting

| Feature | Why It Matters |

|---|---|

| High Accuracy | Cuts within ±0.05mm tolerance |

| No Tool Wear | Same quality from first cut to last |

| Clean Edges | No burrs, usually no need for post-processing |

| Complex Geometries | Can cut intricate, delicate shapes |

| Minimal Distortion | Low heat-affected zone (HAZ) |

Laser cutters can handle detailed parts that would be nearly impossible with punches or saws. For example:

- Tiny holes for filters or speaker grills

- Curved lines in artistic metal signage

- Logo engravings directly on stainless panels

Cutting Comparison:

| Process | Precision | Edge Finish | Tool Change Needed |

|---|---|---|---|

| Laser Cutting | ✅ High | ✅ Very Clean | ❌ No |

| Plasma Cutting | ⚠ Medium | ⚠ Rough | ❌ No |

| CNC Punching | ✅ High | ⚠ Medium | ✅ Yes |

| Waterjet | ✅ High | ✅ Clean | ❌ No |

Laser cutting also reduces human error. Designs go straight from software to machine, removing guesswork. This makes prototyping fast and production repeatable.

Which materials suit CNC laser cutting?

A laser cutter can slice through more than just metal. But material choice affects speed, quality, and safety.

CNC laser cutting is effective on metals like stainless steel, aluminum, and brass, as well as non-metals such as wood, acrylic, leather, and certain plastics.

Different lasers are optimized for different jobs. Fiber lasers are powerful and precise for metals. CO₂ lasers are better for wood, acrylic, and softer materials.

Common Materials and Laser Compatibility

| Material Type | Examples | Compatible Laser Type |

|---|---|---|

| Metals | Steel, aluminum, brass | Fiber |

| Plastics | Acrylic, ABS, polycarbonate | CO₂ |

| Wood | MDF, plywood, solid wood | CO₂ |

| Leather/Textiles | Leather, felt, denim | CO₂ |

| Composites | Carbon fiber, laminates | Specialized |

Material Thickness Guidelines:

| Material | Max Recommended Thickness |

|---|---|

| Mild Steel | Up to 20 mm |

| Stainless Steel | Up to 15 mm |

| Aluminum | Up to 12 mm |

| Acrylic | Up to 20 mm |

| Plywood | Up to 15 mm |

Some materials are unsafe for laser cutting. PVC, for example, releases toxic chlorine gas. Always check compatibility before cutting unfamiliar materials.

Also, reflective metals like aluminum or copper need specialized fiber lasers. They can reflect the beam, which can damage the machine if not properly managed.

Where are CNC laser cutters used?

CNC laser cutters aren't limited to one industry. From high-end tech to household products, their versatility keeps them in high demand.

CNC laser cutters are widely used in industries like aerospace, automotive, signage, electronics, and furniture for cutting parts, panels, and decorative features.

Laser cutting fits well into both high-volume production and small-batch custom work. Industries use it to make everything from structural brackets to custom signs.

Key Application Areas:

| Industry | Use Case Examples |

|---|---|

| Automotive | Chassis parts, gear covers, dashboard panels |

| Aerospace | Lightweight aluminum brackets, ventilation grids |

| Architecture | Decorative panels, ceiling elements |

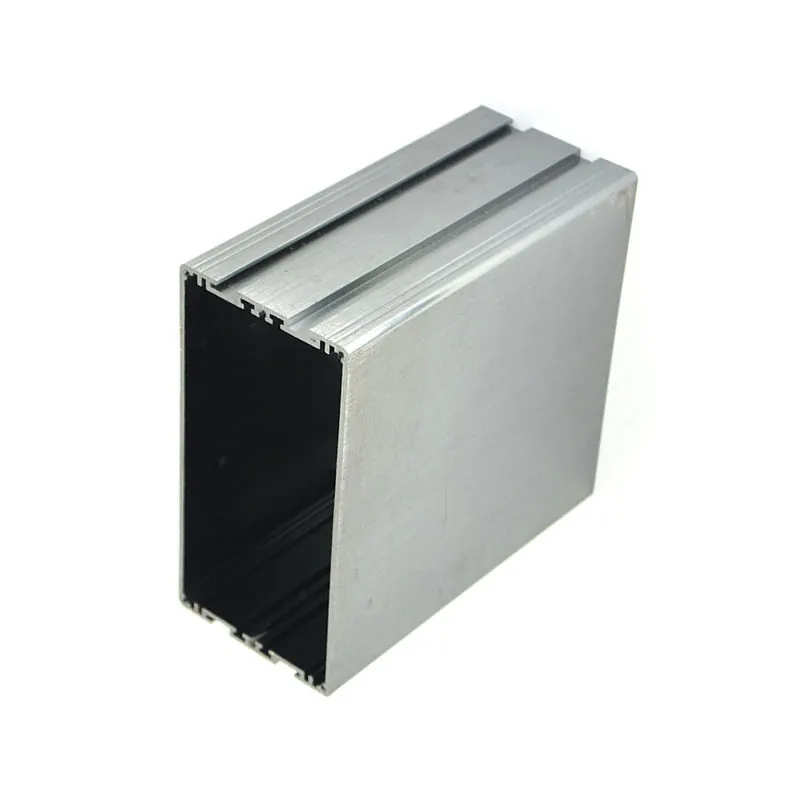

| Electronics | Enclosure cutouts, circuit board panels |

| Furniture | Metal legs, artistic wood components |

| Medical Devices | Precision stainless steel components |

| Advertising/Signage | Illuminated signs, acrylic letters |

Real-World Use Cases:

- In automotive, laser cutters help make lightweight parts with tight tolerances. This improves fuel efficiency and safety.

- In electronics, laser cutters make cutouts in metal and plastic casings, supporting quick design changes.

- In architecture, designers use lasers to cut detailed panels from metal sheets for facades or room dividers.

One key strength of laser cutting is rapid prototyping. Companies can design, test, and iterate in days—not weeks—by simply updating the CAD file.

For small businesses, laser cutters offer a way to create custom products like keychains, signage, and packaging inserts with low startup costs and quick turnaround.

Conclusion

A CNC laser cutter offers a modern solution for cutting with precision, speed, and minimal waste. Whether working with metal, wood, or plastic, it delivers repeatable quality and fine detail. It's a must-have tool across industries that demand efficiency and accuracy.