A CNC machine might seem like a complex tool, but it’s essentially an automated system that does a lot of the heavy lifting in manufacturing. These machines offer precision and efficiency, taking designs from digital files and turning them into real-world products.

CNC (Computer Numerical Control) machines are used in industries around the world to create highly accurate parts. The magic lies in their ability to follow exact instructions, cutting, shaping, and crafting materials with speed and precision. In this article, we'll explore how CNC machines operate, why industries rely on them, what materials they can process, and where they are most effective.

CNC machines have become the backbone of modern manufacturing. Their ability to automate complex processes means businesses can ramp up production while maintaining quality. If you're curious about how these machines work, you're in the right place.

How Does a CNC Machine Operate?

CNC machines follow instructions encoded in a specific programming language to guide their movements. This process begins with a design, usually created using CAD (Computer-Aided Design) software. Once the design is ready, it’s converted into a series of commands called G-code. The CNC machine then interprets these commands, moving the cutting tools with precise control across multiple axes to shape the material.

How It Works:

- Design Creation: Engineers use CAD software to design the part.

- G-code Conversion: The design is converted into G-code, which includes commands for movement, speed, and tool changes.

- Machine Operation: The CNC machine reads the G-code and begins cutting or shaping the material.

The result? The part is made according to exact specifications without human intervention, offering consistency and accuracy.

Why Do Industries Use CNC Machines?

CNC machines bring several advantages to industries that use them. They enhance production speed, quality, and efficiency, all while reducing the chance of human error.

Industries rely on CNC machines because they offer:

- Precision: CNC machines can achieve high tolerances, ensuring parts meet exact specifications.

- Efficiency: These machines can operate continuously, improving production timelines.

- Consistency: CNC machines replicate the same part with high accuracy every time, ensuring no variation.

- Cost-effectiveness: Over time, CNC machining reduces the need for skilled manual labor and decreases material waste.

In short, industries depend on CNC machines for mass production of parts that need to be precise, consistent, and high-quality. Whether it's a single custom part or thousands of identical pieces, CNC machines are designed for scalability.

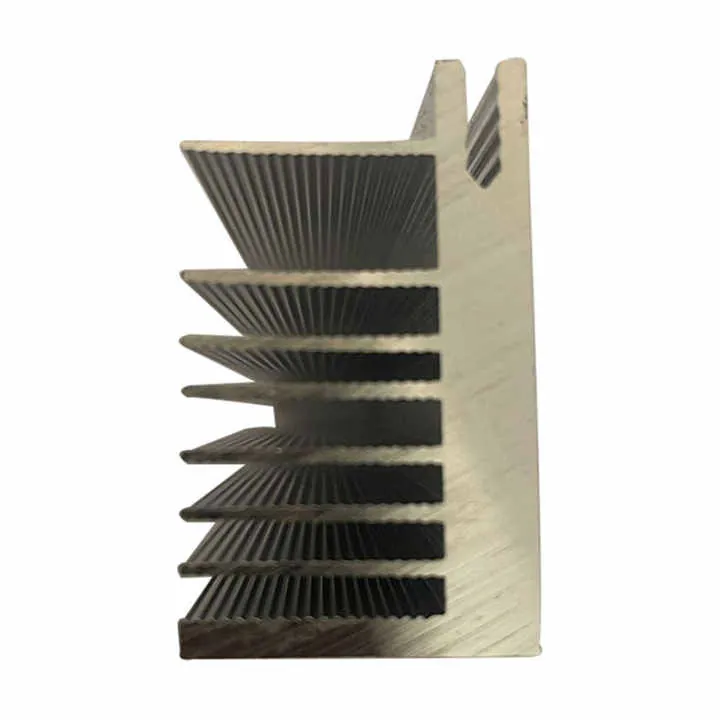

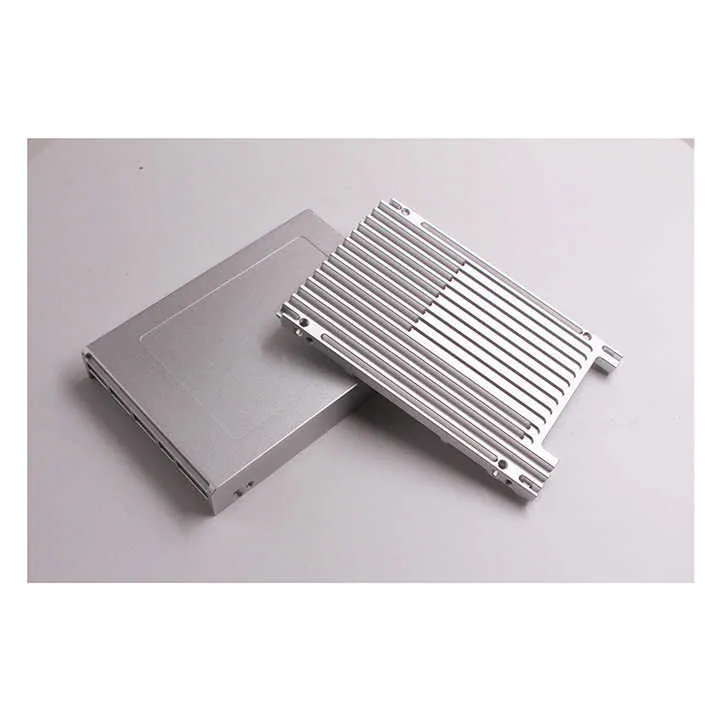

Which Materials Can CNC Machines Process?

CNC machines are incredibly versatile, able to process a wide variety of materials across different industries. These machines can handle:

- Metals: Aluminum, brass, steel, copper, and titanium

- Plastics: PVC, acrylic, nylon, polycarbonate, and more

- Wood: Hardwood, plywood, MDF, and softwood

- Composites: Carbon fiber, fiberglass, and other advanced materials

Common CNC Machined Materials:

| Material Type | Examples | Usage |

|---|---|---|

| Metals | Aluminum, Steel, Copper, Brass | Aerospace, Automotive |

| Plastics | PVC, Nylon, Acrylic | Electronics, Consumer Goods |

| Wood | Hardwood, Plywood, MDF | Furniture, Construction |

| Composites | Carbon Fiber, Fiberglass | Aerospace, Automotive |

This versatility makes CNC machines a go-to tool for almost any manufacturing job. Whether you're working with softwood for furniture or titanium for aerospace parts, CNC machines can be adapted to meet the demands of any material.

Where Are CNC Machines Most Effective?

CNC machines are used in many different industries due to their precision and flexibility. They are especially effective in sectors where quality and accuracy are critical, such as aerospace, automotive, and medical manufacturing.

CNC Machine Applications by Industry:

| Industry | Common Uses | Benefits |

|---|---|---|

| Aerospace | Engine components, turbine blades | High precision, lightweight parts |

| Automotive | Engine blocks, chassis components | Consistent quality, mass production |

| Medical | Surgical tools, implants, prosthetics | Precision for life-critical parts |

| Electronics | Circuit boards, connectors | Small, intricate parts |

In aerospace and automotive industries, for example, CNC machines are used to create parts that need to meet strict tolerances and standards. These industries benefit from the repeatability and speed that CNC machines offer, helping them stay competitive while maintaining product quality.

Conclusion

In summary, CNC machines are vital in modern manufacturing. Their precision, efficiency, and ability to work with a wide range of materials make them essential tools across numerous industries. Whether producing automotive parts, medical devices, or custom furniture, CNC machines are the foundation of many high-quality products.