I remember how messy metal work looked before CNC machines, but then everything changed fast. It felt like chaos — until CNC stepped in.

A CNC machine is a computer‑controlled tool that automates cutting, drilling, or shaping materials with high accuracy. It converts digital designs into precise physical parts.

CNC machines moved metalworking and fabrication from rough hand tools to clean, automated precision. They solve issues of inconsistency and slow production while giving scalability.

I will show how CNC works, why it matters, where it is used, and which industries rely on it.

What is the purpose of a CNC machine?

CNC machines help turn digital blueprints into real parts at scale. They fix human error and reduce waste quickly.

The main purpose is to automate and standardize machining tasks so that parts come out uniform, repeatable, and accurate — from one batch to thousands.

A CNC machine’s purpose goes beyond just cutting metal. It often replaces manual lathes, mills, and drills. When a craftsman uses hand tools, even skilled workers can produce slight differences. CNC removes that uncertainty. It follows exact instructions from a computer model.

CNC also helps reduce material waste. When a machine cuts exactly where needed, leftover material is minimized. That matters when working with expensive metals. CNC speeds up production. A part that takes hours manually can be done in minutes with CNC.

CNC also improves worker safety. Sharp tools move fast, but the human does not need to guide them close by. The operator loads material, presses start, and stands clear. That reduces the risk of injury.

CNC ensures quality across large runs. If you need 1 part, CNC is good. If you need 1000, CNC keeps every part nearly identical. That consistency is key for assemblies and large systems.

CNC lowers labor cost. A single machine may run for hours unattended. It reduces the need for many skilled operators. Companies often use fewer workers while increasing output. That raises efficiency and lowers cost per part.

When design changes happen, CNC adapts fast. Engineers change a CAD file. Then the machine follows the new design exactly. No need for new tool setups or manual adjustments. That agility saves time and money.

Because of these benefits, many factories use CNC to start their production. CNC helps turn design intent into real, reliable parts with less waste, lower cost, and consistent quality.

How does CNC automation enhance precision?

CNC machines follow digital instructions precisely, which cuts human error almost completely. They hit targets within tiny tolerances every time.

CNC automation uses computer control to make each movement exact, so machines can cut or shape parts with very tight tolerances and repeat accuracy.

CNC uses numerical control. That means the machine reads numbers and coordinates from a digital plan. It moves tool heads in X, Y, Z axes very precisely. That precision beats human hands again and again.

High Tolerance and Repeatability

CNC can hold tolerances of a few thousandths of an inch or hundredths of a millimetre. That is hard to match with hand tools. Once the machine is calibrated, it repeats measurements every time.

| Feature | Manual Machining | CNC Machining |

|---|---|---|

| Typical tolerance | ±0.005 inch or more | ±0.001 inch or less |

| Repeatability over 100 parts | High variation possible | Very little variation |

| Setup time | Short for single part, longer for many | Longer initial setup, then fast for batch |

Because CNC reads from CAD files, the design is exact. The tool path is calculated before cutting starts. That avoids mistakes like cutting too deep or skipping details. CNC checks its own path and can pause if it recognizes a problem.

CNC also handles complex shapes more easily than manual tools. Curves, arcs, holes at odd angles, pockets — CNC handles them without human guesswork. Even 3D surfaces or curved contours become possible with a 5‑axis CNC.

Less Human Error, More Consistency

Humans get tired or distracted. A hand file may slip, a cut may wobble, or a drill may shift. CNC does not suffer fatigue. As long as the machine is well maintained, it performs consistently day after day.

CNC reduces manual touch points. That lowers chances for small but costly mistakes. Once CNC cuts a batch, every piece matches the intended design closely. That consistency is crucial when parts need to fit together tightly.

Speed Combined With Precision

CNC does not trade precision for speed. Instead, it gives both. The machine can move fast, but its motions are controlled in tiny steps. That means many parts can be made quickly without losing quality.

Fast cycles matter when demand is high or deadlines are tight. Companies can get high volumes without sacrificing quality. This mix of speed and precision is one of CNC’s greatest strengths.

Because of this, CNC machines raise the floor for what manufacturing can do. They allow precise, repeatable parts that manual methods can’t match, especially for complex or high-volume parts.

Where are CNC machines commonly used?

CNC machines appear in small workshops and large factories worldwide. They are common wherever precise shaping of metal, plastic, or wood is needed.

CNC machines are used in machine shops, metal fabrication shops, prototyping labs, and manufacturing floors, wherever parts need precision shaping or drilling.

Many small machine shops use CNC to build custom parts. A local workshop making car parts or custom tools may use a 3‑axis mill or lathe. They get consistent parts faster than manual methods. That boosts their competitiveness.

Prototyping labs often rely on CNC. When engineers design a new product, they send CAD files to a CNC machine. The machine produces a physical prototype quickly. That helps test fit and function before mass production.

CNC is also common in factories making parts for assemblies. For example, a factory making metal brackets, housings, frames, or structural pieces might use CNC to cut and shape parts before welding or finishing. CNC ensures all parts match tight specs.

Some shops use CNC for tooling. Tools like molds, dies, jigs, or fixtures often require precise geometry. CNC shapes these tools with high accuracy. That helps when the tools themselves later produce many parts.

Even small businesses use CNC for specialty woodworking. Furniture makers or sign makers use CNC routers. They cut wood or plastic precisely to match design files. That lets them produce custom pieces or repeated designs with consistent quality.

Common CNC Machine Types

| CNC Machine Type | Common Materials | Typical Use |

|---|---|---|

| CNC Milling Machine | Metal, plastic, wood | Cutting, shaping, pockets, surfaces |

| CNC Lathe | Metal, plastic | Turning cylindrical parts, threads |

| CNC Router | Wood, plastic, soft metals | Sign making, wood carving, light fabrication |

| 3D CNC Machine / Machining Center | Metal, composites | Complex multi‑surface machining, multi‑axis work |

Large factories often have multiple CNC machines lined up. Each may run different tasks: some drilling, some milling, some turning. The output moves to assembly or finishing lines.

In short, CNC machines are everywhere you find shaped parts — from metal brackets to wooden furniture. They serve both custom, one‑off tasks and big volume production.

What industries rely on CNC technology?

Many industries depend on CNC — from automotive and aerospace to electronics, furniture, and even art. CNC supports rigid standards, high precision, and large scale.

Industries such as aerospace, automotive, electronics, metal fabrication, woodworking, and medical device manufacturing rely heavily on CNC technology for precise parts and scalable production.

CNC plays a key role in automotive manufacturing. Car parts like engine blocks, transmission cases, brackets, and chassis components must meet strict tolerances. CNC machines produce these parts fast and accurate. That ensures consistency and safety in vehicles.

In aerospace, precision is even more critical. Parts for aircraft frames, engine components, landing gear, or instrumentation housings need exact shapes and tight tolerances. CNC machining meets these tough standards. CNC also handles exotic materials like titanium or high‑strength alloys.

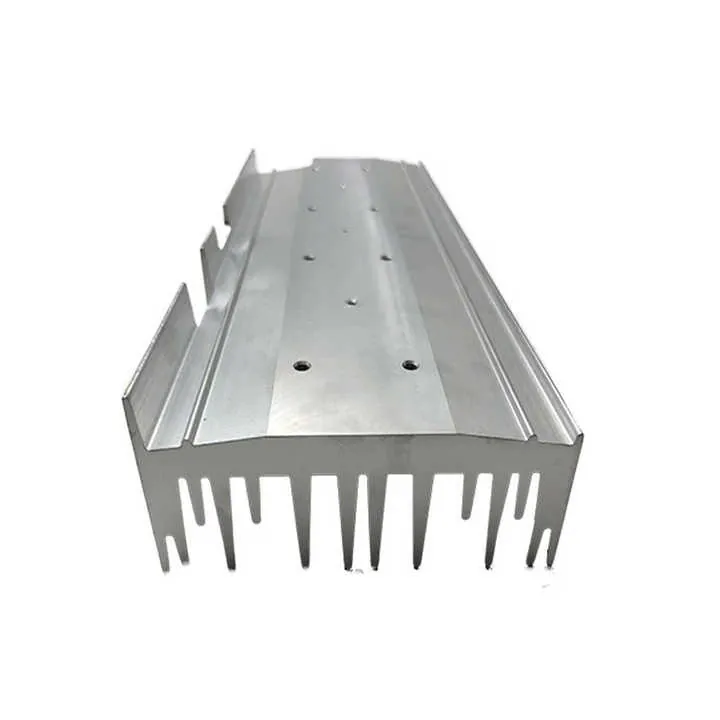

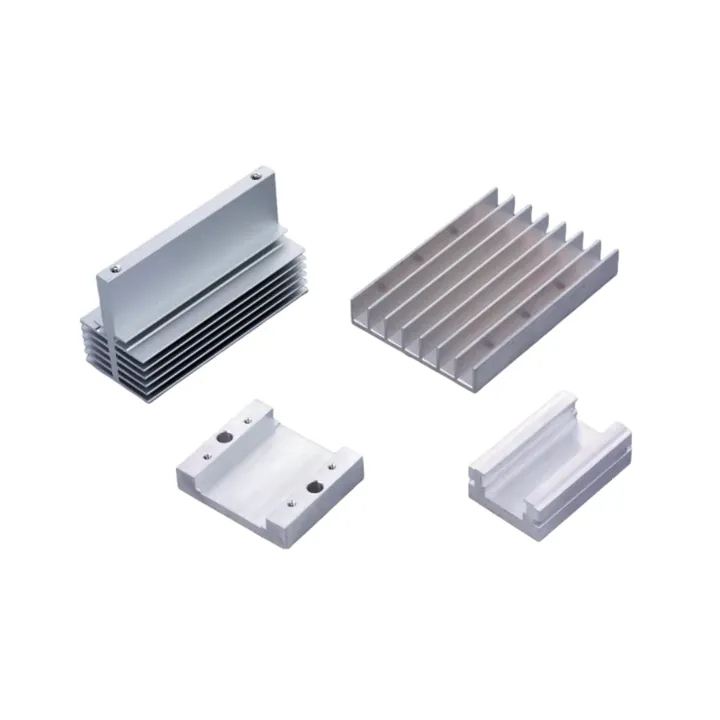

Metal fabrication industries use CNC to make frames, housings, enclosures, structural components, and custom parts. Factories process sheet metal, plates, and blocks to build machinery parts. CNC ensures repeatability and batch uniformity.

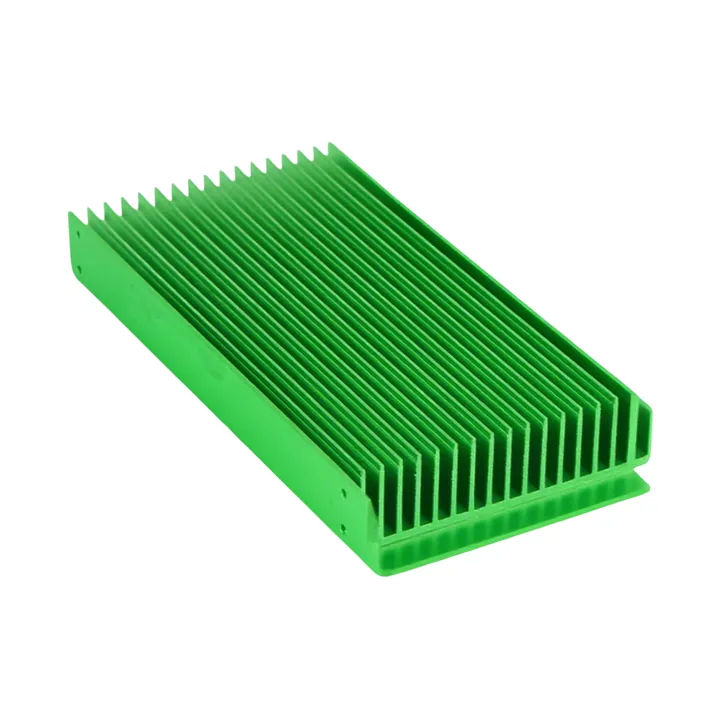

Electronics industry relies on CNC for parts like heat sinks, enclosures, components for circuit boards, chassis, and frames. CNC machining helps meet thermal, structural, and size requirements accurately.

CNC also appears in medical device manufacturing. Surgical tools, implants, device housings, and instrument parts often need very precise dimensions and clean finishes. CNC ensures high quality and compliance.

Woodworking and furniture industries use CNC routers for custom furniture, cabinetry, decorative panels, and signage. CNC allows creative design, precision cuts, and batch runs with consistent quality.

CNC Across Industries: Summary

| Industry | Common CNC Use Cases | Why CNC Matters |

|---|---|---|

| Automotive | Engine parts, brackets, chassis components | Precision, consistency, high volume |

| Aerospace | Frames, engine parts, landing gear, housings | Tight tolerances, exotic materials, repeatability |

| Electronics | Housings, heat sinks, structural parts | Accuracy, small features, batch parts |

| Medical Devices | Implants, surgical tools, device parts | Clean finish, precision, regulatory compliance |

| Metal Fabrication | Frames, enclosures, custom parts | Flexibility, repeatability, custom orders |

| Woodworking & Furniture | Cabinets, panels, decorative pieces | Design flexibility, batch production |

Because of CNC, industries can meet strict quality standards and mass‑produce complex parts without human error. CNC also supports custom work at scale.

Conclusion

CNC machines convert digital designs into real parts fast, precise, and consistent. They add speed, accuracy, and reliability. Industries from cars to medical tools depend on CNC. CNC changed manufacturing in deep ways that will keep evolving.