In today’s fast-paced manufacturing world, traditional tools struggle to keep up. Mistakes, delays, and inconsistent results are common. This is where CNC machines come into play.

A CNC machine is a computer-controlled manufacturing tool that automates and improves precision, speed, and consistency in production processes across industries.

Modern industries rely on speed, accuracy, and repeatability. Manual methods can't match the efficiency of automated solutions. To stay competitive, many factories now rely on CNC technology.

What are the main components of a CNC machine?

Many people misunderstand how CNC machines work. They think it's all about software or the cutting head. But in reality, the machine's performance depends on how well all its parts work together.

The main components of a CNC machine include the controller, machine bed, spindle, motors, tool changers, and feedback systems—all working together to produce precise parts.

To understand a CNC machine, we can break it down into core parts:

1. Controller

This is the brain. It interprets G-code instructions and sends signals to the motors and drives. The controller handles positioning, speed, and tool changes.

2. Machine Bed

This base supports the entire machine. It's usually made from cast iron or steel for stability. It absorbs vibrations and ensures rigidity during machining.

3. Spindle

The spindle holds the cutting tool. It rotates at high speeds and varies based on the material and cutting operation. Some machines have multiple spindles.

4. Motors and Drives

These move the machine along its axes—X, Y, and Z. Servo motors offer high precision and are often used with encoders for feedback. Stepper motors are simpler and used in less demanding systems.

5. Tool Changer

Automatic tool changers (ATC) allow machines to switch tools without stopping. This saves time and supports complex machining tasks in one run.

6. Feedback System

Also called a closed-loop system, it uses encoders and sensors to detect the exact position of machine parts. This ensures the tool follows the correct path.

Here's a quick summary:

| Component | Function |

|---|---|

| Controller | Processes commands and controls movement |

| Machine Bed | Provides support and reduces vibration |

| Spindle | Rotates the tool for cutting |

| Motors & Drives | Move machine parts precisely |

| Tool Changer | Automatically switches tools |

| Feedback System | Monitors accuracy and position |

Each part matters. If one component fails or is misaligned, the final product may be inaccurate. That’s why maintenance is key.

Why are CNC machines used in modern manufacturing?

Manufacturers face pressure to deliver high-quality parts faster and cheaper. Traditional machining takes time and needs skilled workers. It's hard to repeat the exact result every time.

CNC machines are used in modern manufacturing because they provide speed, accuracy, repeatability, and lower labor costs, making them ideal for both large-scale and precision production.

CNC machines don't just cut metal. They change how factories work. Let’s explore the key reasons:

Precision and Accuracy

Every part made on a CNC machine follows a digital blueprint. This reduces human error. Machines can achieve tolerances as tight as 0.001 mm, critical for aerospace and automotive industries.

Repeatability

Once the design is programmed, the same part can be produced thousands of times with no variation. That level of consistency is hard to match manually.

Efficiency

CNC machines run 24/7 with little supervision. Tool changes, speed adjustments, and even part orientation are automated. Less downtime means more parts per hour.

Safety

Operators interact less directly with cutting tools. Enclosures, sensors, and automatic shut-offs reduce injury risks.

Cost Savings

Although CNC machines are expensive initially, they lower long-term costs:

- Fewer mistakes mean less wasted material.

- One operator can manage multiple machines.

- Faster production reduces per-part costs.

Here's a table comparing CNC and manual machining:

| Feature | CNC Machining | Manual Machining |

|---|---|---|

| Accuracy | Very High | Depends on operator |

| Labor Requirement | Low | High |

| Speed | Fast | Slower |

| Repeatability | Excellent | Limited |

| Skill Dependency | Lower | Higher |

Manufacturers use CNC machines to stay competitive. Whether it’s a batch of engine parts or custom furniture components, CNC delivers.

How does a CNC machine improve productivity?

Many shops struggle to meet deadlines or ramp up production. Manual tools slow things down and increase the chance of errors.

CNC machines improve productivity by automating operations, reducing downtime, and allowing one operator to manage several machines with minimal errors.

Productivity isn't just about speed. It's about making more, with fewer mistakes, in less time. Here's how CNC helps:

Faster Setup

Once the G-code is loaded, setup is minimal. Fixtures and jigs are standardized. Some systems even have automatic part loading.

Unattended Operation

CNC machines can run overnight or during weekends without supervision. This is called "lights-out manufacturing." While people sleep, parts are being made.

Multitasking

Some machines combine milling, turning, drilling, and tapping in one setup. This reduces the need to transfer parts between machines.

Software Simulation

Before machining begins, software simulates the toolpath. Errors can be caught early, preventing machine crashes and waste.

Quick Tool Changes

Automatic changers and preset tool holders allow machines to switch tools in seconds. There's no need to stop production.

Less Rework

Because of high accuracy, parts usually meet quality standards on the first try. This reduces inspection time and rework costs.

Centralized Control

Modern systems allow operators to monitor multiple machines from a single panel. Some use cloud-based dashboards to track productivity remotely.

All these factors add up. In high-volume operations, CNC machines might produce 5x more parts than manual machines in the same time frame.

Where are CNC machines used?

Some assume CNC is only for making car parts or aerospace components. But CNC touches almost every industry you can think of.

CNC machines are used across industries like automotive, aerospace, medical, construction, electronics, and furniture, making parts from metal, plastic, wood, and even glass.

Let’s look at key industries using CNC today:

Automotive

From engine blocks to dashboards, many car parts are CNC machined. The need for high precision and large volume makes CNC ideal.

Aerospace

Aircraft parts need tight tolerances and reliable materials. CNC machines cut titanium, aluminum, and composites into parts like turbine blades and brackets.

Medical

CNC helps make surgical tools, implants, and prosthetics. Many of these are custom-made to fit individual patients.

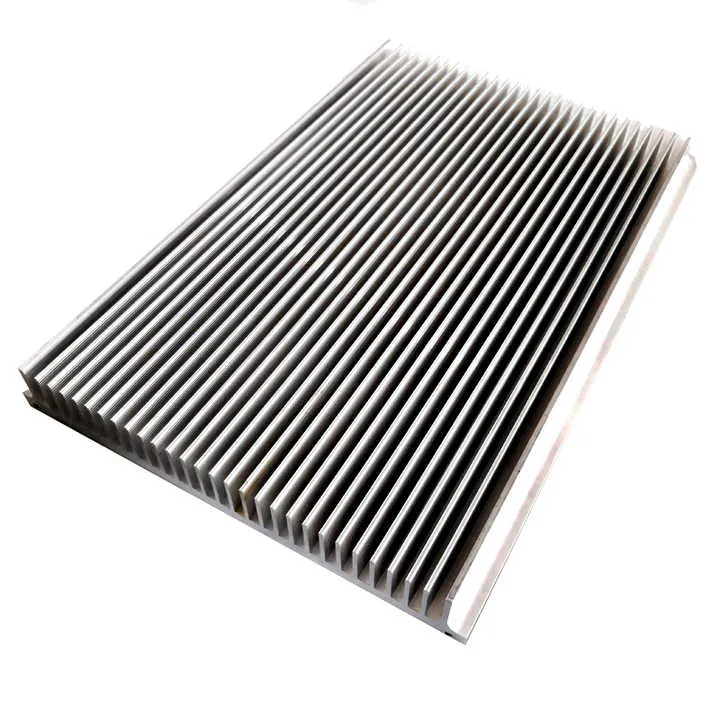

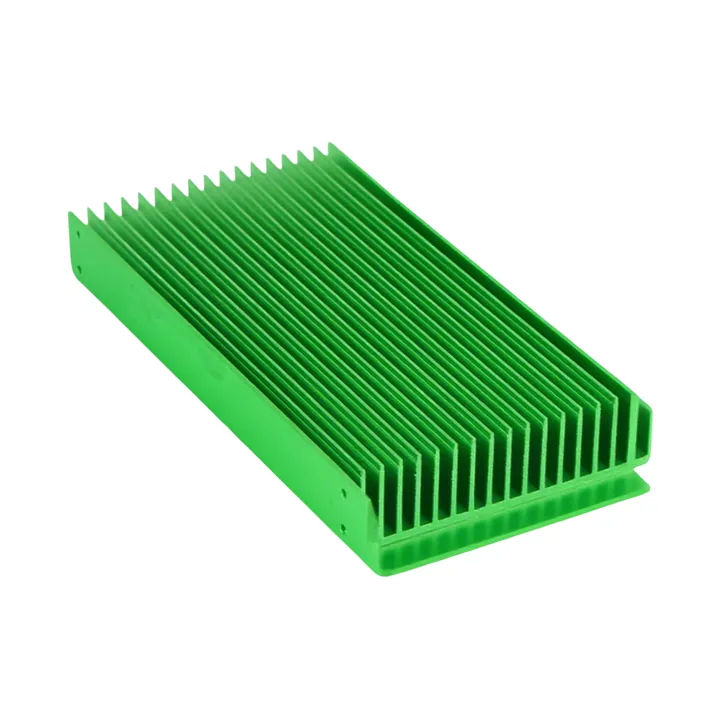

Construction

CNC machines cut aluminum profiles for windows, doors, curtain walls, and structural components. Large aluminum extrusions are often finished with CNC milling for accuracy.

Electronics

Phone housings, circuit boards, and connectors are often CNC machined. Tiny details require high precision.

Furniture

CNC routers cut and engrave wood panels for cabinets, desks, and chairs. Designs can be customized easily using software.

Here’s a quick overview:

| Industry | CNC Applications |

|---|---|

| Automotive | Engine parts, transmission housings, chassis |

| Aerospace | Wing sections, turbine parts, landing gear |

| Medical | Implants, surgical tools, braces |

| Construction | Aluminum profiles, brackets, window frames |

| Electronics | Phone parts, PCB prototypes, enclosures |

| Furniture | Custom panels, carvings, precision joinery |

Each industry uses CNC differently. But the goal is always the same: better quality, faster delivery, and consistent results.

Conclusion

CNC machines are at the heart of modern manufacturing. They bring together hardware, software, and automation to make production faster, smarter, and more reliable across industries.