Starting a project without good tools is hard. Many shops waste time with slow machines or manual work that leads to errors and delays. A CNC machining center solves these problems fast and precisely.

A CNC machining center is a computer-controlled machine that can cut, shape, and finish materials like metal or plastic. It uses programmed instructions to work automatically with speed and high accuracy.

This article explains how these machines operate, why people use them, what tasks they can do, and where they are used in real life. It should help anyone to grasp the power of CNC machining centers.

How do machining centers operate?

Starting with old manual machines often causes mistakes and slow work. CNC machine centers make that problem go away by using code and automation to guide each move with precision.

A machining center runs by reading a coded program (usually G‑code) that tells it where to move tools, how fast to spin them, and how deep to cut. The computer controls vertical and horizontal motion to shape parts precisely.

A CNC machining center uses a set of steps to operate. First, a designer creates a digital model of the part using CAD (computer-aided design). Then the model is turned into a toolpath with CAM (computer-aided manufacturing) software. This toolpath becomes G‑code, a sequence of instructions the machine controller reads. The controller sends commands to motors that move the spindle and the table. The spindle holds the cutting tool (drill, mill, etc.) and rotates it at high speed. The table moves the workpiece along X, Y, and sometimes Z axes. As a result, the tool shapes the material exactly as the digital design.

Main components

- Controller: The “brain” that interprets G‑code and controls motion and speed.

- Spindle: The rotating part that holds and spins tools.

- Axes and table: The frame that moves the material under the tool.

- Tool changer (optional): Automatically swaps tools for multi-step jobs.

- Coolant and chip removal: Keep heat down and clear cutting debris.

A modern machining center often includes an automatic tool changer. The machine can swap a drill for an end mill, then for a tap, all without stopping. This saves time and reduces manual work.

Safety and precision matter. The machine encloses the work area to protect operators from chips and coolant. Sensors may detect tool wear or overload. If something is off, the machine can pause or alarm. This reduces scrap and protects operators.

Speed and consistency are key. A CNC machining center performs the same operation without fatigue. It does not depend on human skill. Each piece comes out nearly identical. This is ideal for small batches or large production runs.

Overall, a machining center runs on digital design and automated motion control. It transforms raw material to finished parts with high precision and repeatability. Most users get better quality and faster turnaround than with manual machines.

Why choose machining centers?

Many shops still cut and shape parts by hand or with older machines. That often causes delays, errors, and more waste. Using a CNC machining center can solve these issues while improving quality and productivity.

Machining centers offer automation, precision, speed, and flexibility. They reduce human error, lower waste, and let users make complex shapes with ease. Those benefits often outweigh higher initial investment.

A machining center gives clear advantages over manual machines or simpler tools. First, precision: the machine moves tools with tiny increments, often under 0.01 mm. That makes parts very accurate. Second, repeatability: if you need many identical parts, CNC produces each one the same way. Third, speed: CNC can run faster, change tools automatically, and often work 24/7 with minimal supervision. Fourth, flexibility: changing the part design often means only updating the program, not building new physical setups.

Cost‑benefit over time

Although a machining center costs more to buy, it reduces labor, scrap, and rework. Over time, it pays for itself.

| Benefit | Impact on operation |

|---|---|

| High precision | Less measurement check, better fit between parts |

| Repeatability | Consistent output across many parts |

| Reduced labor cost | Less manual work needed, operator can manage multiple machines |

| Lower scrap rate | Less wasted material through errors |

| Faster turnaround | Shorter production time, faster delivery |

Flexibility makes machining centers especially useful when designs change often. For example, in a manual shop, changing a part needs remaking fixtures, retraining workers, or redoing setup. In a CNC environment, you just load new code. That saves days and reduces risk of mistakes.

Safety and operator comfort also improve. Operators do not need to handle tools constantly or watch every cut. The machine runs within a closed area, and coolant systems manage dust and debris. That makes shop environment cleaner and less dangerous.

Machining centers allow small shops to compete with larger factories. A small team with CNC machines can deliver precise parts at high volume. That makes shops more competitive and opens more business possibilities.

Because of these reasons — automation, precision, efficiency, flexibility — many modern manufacturers choose CNC machining centers over older methods.

Which processes machining centers handle?

Many think machining centers just drill holes or cut basic shapes. In fact, they can do much more. A single machine can perform multiple tasks in one setup. That saves time and reduces handling errors.

Machining centers can do milling, drilling, boring, tapping, contouring, and sometimes light cutting operations such as slotting or shaping. They can also handle surface finishing steps, all in one cycle.

A machining center can perform a variety of machining processes. The most common are:

- Milling: removing material with rotating cutters to shape surfaces.

- Drilling: creating holes of different diameters.

- Boring: enlarging existing holes with fine accuracy.

- Tapping: cutting internal threads inside holes.

- Contour machining: shaping complex curves or angled surfaces.

- Facing and slotting: flattening surfaces or cutting slots.

Why multiple processes in one machine matter

In a traditional workshop, each process may require a different machine or setup. That means moving the workpiece several times. Every move adds risk of misalignment or damage. With a machining center, a part can undergo drilling, milling, tapping all in one run.

That saves time and improves accuracy. It also reduces the need for extra fixtures. The part stays on the same table, under the same reference frame. That keeps tolerances tight.

Example case: part production flow

| Stage | Operation | Tool used |

|---|---|---|

| 1 | Rough milling | End mill cutter |

| 2 | Hole drilling | Twist drill |

| 3 | Hole finishing / boring | Boring head |

| 4 | Thread cutting | Tap tool |

| 5 | Surface finishing | Chamfer or finishing mill |

In a single setup, the machine might start with rough milling to remove bulk material. Then it drills holes. Then it bores some holes for better accuracy. Next, it taps threads if needed. Finally, it may mill a chamfer or smooth the edges. No manual repositioning is needed between steps.

This capability reduces human work and improves throughput. Shops can deliver parts faster and with fewer mistakes.

In some advanced machining centers, operators can also load custom fixtures or jigs to position several parts at once. The machine then repeats the same operations on each part. That is efficient when producing batches.

Because of this multi-process ability, machining centers handle many tasks normally done by several machines. That makes them ideal for modern manufacturing.

Where are machining centers used?

Many industries still use manual lathes or fabrication. That limits what they can build and slows production. Machining centers change that. They appear where parts must be precise, strong, and repeatable.

Machining centers are used in industries such as automotive, aerospace, electronics, construction machinery, mold making, and general metal fabrication. They appear wherever precision parts and repeatable manufacturing are needed.

Machining centers are everywhere in modern manufacturing. Some major sectors:

- Automotive: engine blocks, brackets, transmission parts.

- Aerospace: aircraft components, structural parts, landing gear parts.

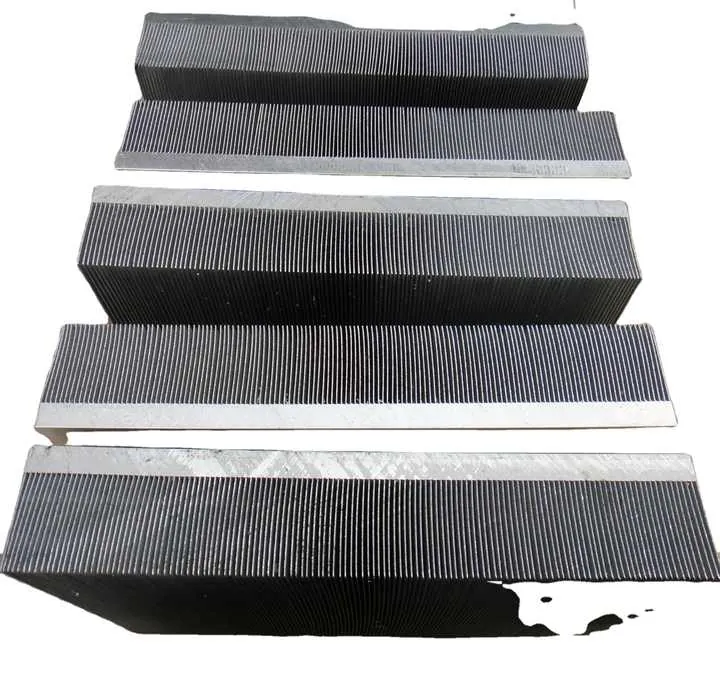

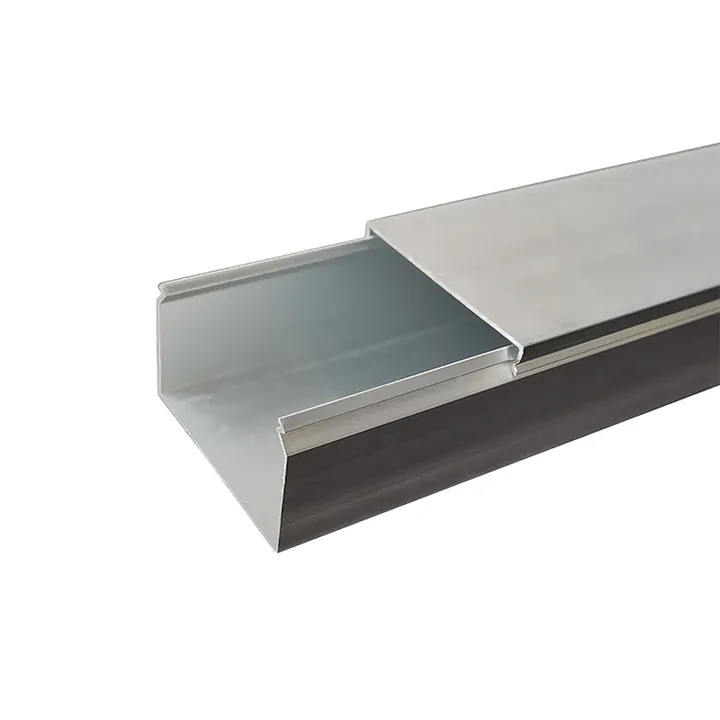

- Electronics and telecom: housings, heat sinks, connectors.

- Construction and heavy machines: frames, mounts, structural parts.

- Mold and die making: molds for plastic injection, metal casting.

- General manufacturing and prototyping: custom parts, small batch runs.

Why these industries need CNC centers

These industries demand tight tolerances, repeatable parts, and often complex shapes. Manual work cannot guarantee consistency at scale. Machining centers give precise control over geometry, surface finish, and dimensions.

Also, many of these industries require different materials. Machining centers can work with aluminum, steel, alloys, even some plastics. That versatility helps makers shift quickly among product types.

Sample list of industries and typical parts

| Industry | Typical parts made |

|---|---|

| Automotive | Engine parts, suspension mounts, gearbox housings |

| Aerospace | Wing brackets, fuselage components, landing gear parts |

| Electronics | Heat sinks, metal housings, connector plates |

| Construction machinery | Hydraulic blocks, chassis parts, structural frames |

| Mold & Die | Injection molds, die casts, stamping molds |

Because machining centers reduce time and cost per part, they work well for both mass production and small-batch custom jobs. Many workshops use them for prototypes to test new designs. Once design is approved, they use same machines for mass production. That makes transitions smooth and efficient.

In places where quality and safety matter—like aerospace or automotive—machining centers help ensure parts meet strict standards. Consistent quality lowers risk of failure. Machines also log data, so traceability improves.

Overall, machining centers serve many industries because they combine precision, versatility, and speed. They help turn raw metal into finished parts that meet high standards.

Conclusion

CNC machining centers give shops a modern way to build precise, complex parts with less effort. They cut waste, save time, and support many industries. For any company needing custom or high‑volume metal work, a machining center offers clear advantages.