Making signs, panels, or furniture by hand is slow and inconsistent. But with a CNC router, even complex cuts become fast, clean, and repeatable.

A CNC router is a computer-controlled cutting machine used for shaping wood, plastics, composites, and soft metals, making it ideal for signage, cabinetry, and prototyping.

This tool is trusted by manufacturers, artists, engineers, and hobbyists. Let’s break down how it works, why it's so useful, and where it fits into modern production.

How does a CNC router work?

Cutting material manually takes practice and skill. CNC routers remove the guesswork by following digital paths with precision.

A CNC router works by using a spinning cutting tool mounted on a moving gantry to carve designs based on computer-generated instructions (G-code).

The machine follows commands from a CAD/CAM file. It moves the router bit across the material in multiple directions—usually along X, Y, and Z axes. The router spins rapidly, cutting through or carving into the material below.

How It Works – Step by Step:

- Design Creation – Use CAD software to design the part or artwork

- Toolpath Generation – Convert the design to G-code with CAM software

- Material Setup – Place and secure material on the router bed

- Machine Operation – CNC router follows the toolpaths to cut or engrave

- Finishing – Clean edges, sanding, painting, or assembly

Common Features of a CNC Router:

| Component | Function |

|---|---|

| Router Spindle | Holds and spins the cutting bit |

| Gantry System | Moves the spindle in X and Y directions |

| Z-Axis Control | Moves the bit up and down for depth cuts |

| Table/Bed | Flat surface for placing materials |

| Control System | Reads G-code and directs all motion |

CNC routers can perform a range of operations, such as:

- Profile cutting

- Pocketing

- Drilling

- 3D carving

- Inlay work

- Surface engraving

Some routers have vacuum beds to hold sheets in place, making them even more efficient for large projects.

Why use a CNC router for wood or plastic?

Cutting wood or plastic manually can lead to uneven edges, splintering, and wasted materials. CNC routers fix all of that.

A CNC router is perfect for wood and plastic because it produces smooth, accurate cuts, supports complex shapes, and reduces waste during production.

Unlike traditional saws or handheld routers, CNC routers move precisely according to the design file. This ensures repeatable quality, even on intricate patterns or curves.

CNC Routers vs. Traditional Methods:

| Feature | CNC Router | Manual Cutting |

|---|---|---|

| Precision | ✅ High | ⚠ Depends on operator skill |

| Complex Shapes | ✅ Easily supports curves/3D cuts | ⚠ Difficult or impossible |

| Repeatability | ✅ Identical results | ⚠ Varies per cut |

| Waste Reduction | ✅ Optimized toolpaths | ⚠ Often higher scrap |

| Time Efficiency | ✅ Faster once programmed | ⚠ Slower, especially on large jobs |

CNC routers are ideal for:

- Custom cabinetry with unique patterns

- Signage with lettering or logos

- Plastic housings or product prototypes

- Decorative wall panels or moldings

- Furniture components that require precise joinery

Because routers use rotating bits instead of blades, they create clean edges with minimal burn or melt—important for plastics like acrylic or polycarbonate.

Which materials can a CNC router cut?

While routers are best known for cutting wood, they handle much more. The right bit and speed settings allow them to shape many materials.

CNC routers can cut wood, plywood, MDF, plastics like acrylic or PVC, foam, composites, and even soft metals like aluminum or brass.

Compatible Materials for CNC Routing:

| Material Type | Examples | Typical Uses |

|---|---|---|

| Hardwood | Oak, maple, walnut | Furniture, cabinetry, trim work |

| Softwood | Pine, spruce | Signage, construction, carvings |

| Plywood/MDF | Engineered wood sheets | Paneling, fixtures, displays |

| Plastics | Acrylic, polycarbonate, HDPE | Signs, product casings, light fixtures |

| Foam | Polystyrene, PU foam | Prototyping, molds, signage |

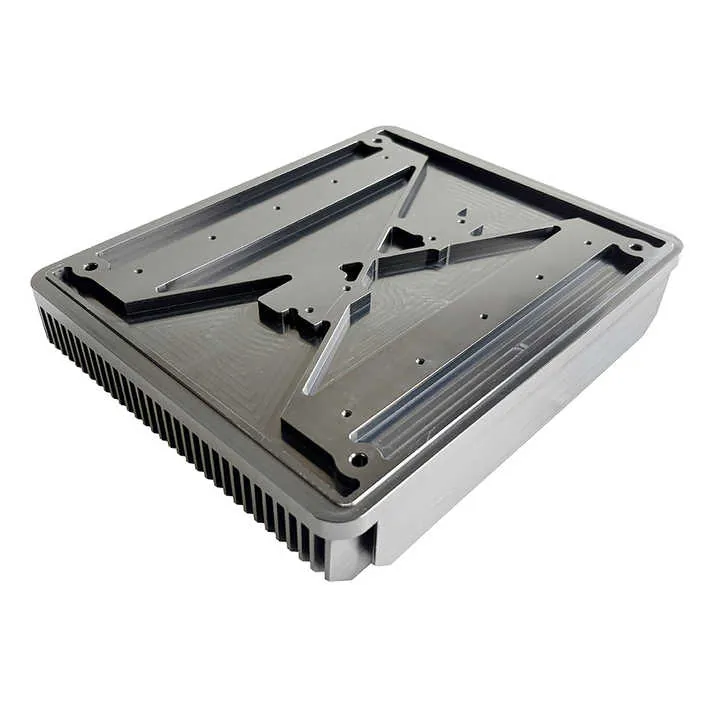

| Soft Metals | Aluminum, brass | Panels, enclosures, logo plates |

| Composites | Carbon fiber, fiberglass | Tooling, auto parts, structural inserts |

Not all CNC routers can cut metal, but many industrial models can handle soft metals if proper tools and speeds are used.

Material Tips:

- For wood: use sharp, upward-spiral bits to avoid burning

- For plastics: use single-flute bits to reduce melting

- For foam: use low-speed, large-flute bits to avoid tear-out

- For aluminum: use specialized coolant and slower feeds

Some routers are hybrid machines that also allow laser engraving or plasma cutting, expanding their use beyond simple routing.

Where are CNC routers applied?

CNC routers are not limited to factories. They are used in workshops, design studios, schools, and creative businesses.

CNC routers are applied in furniture making, sign production, interior design, product prototyping, and artistic fabrication where precision and repeatability are required.

From personalized gifts to full-scale architectural features, CNC routers bring creativity and control together.

Key Application Areas:

| Industry | CNC Router Uses |

|---|---|

| Furniture | Chairs, tables, joinery, panels |

| Signage | Lettering, 3D logos, illuminated signs |

| Interior Design | Wall art, room dividers, ceiling details |

| Prototyping | Plastic enclosures, foam models, mockups |

| Education | STEM projects, CNC training, school displays |

| Construction | Custom panels, cladding, formwork molds |

| Retail & Display | Store fixtures, signage, branding elements |

Real-World Examples:

- A custom furniture maker cuts curved chair legs with perfect symmetry

- A sign shop produces dozens of acrylic signs with logos in one day

- A student uses a CNC router to carve out parts for a school robot

- A design studio creates wall art from layered plywood panels

Routers also allow small businesses to compete with mass producers—offering custom, high-quality results without massive investment.

Conclusion

A CNC router is a powerful, flexible machine that makes cutting wood, plastic, and other soft materials fast and precise. Whether you're producing signs, furniture, or creative prototypes, it adds speed, quality, and design freedom to your work.