Many engineers see the spindle inside a CNC machine and wonder how it really works and why it matters. What makes this spinning part so critical?

A CNC spindle is the rotating axis of a CNC machine. It drives cutting tools, defining speed and accuracy. Without a healthy spindle, no precise machining is possible.

Spindles power the cutting, shaping, and drilling in CNC machining. Understanding them helps you see how parts get made and why quality depends heavily on the spindle’s design and performance.

How does a CNC spindle work?

CNC spindles may look simple from outside. Inside, they spin at high speeds and move with great stability.

The spindle works by holding the cutting tool in a rigid setup and rotating it at controlled speed while delivering torque as per machining needs.

A CNC spindle functions like this. First, the machine’s controller sends instructions: what tool, what speed, which direction. The spindle holds the tool firmly in a chuck or collet. Then a high‑precision motor spins the spindle. The workpiece sits fixed or moves on a table. The spinning tool contacts the material and removes chips.

What are the main parts inside a spindle?

| Component | Role |

|---|---|

| Motor or drive unit | Provides torque and rotation at required RPM |

| Bearings | Support the spindle and ensure smooth rotation with minimal wobble |

| Tool holder (collet/chuck) | Securely grips the cutting tool |

| Spindle shaft | Transmits torque from motor to tool holder |

| Cooling/lubrication system | Keeps temperature and friction under control during high‑speed operation |

The motor inside the spindle can be electric or take power from external drives. When the machine starts, the motor spins the shaft. Bearings keep the shaft aligned. The tool holder keeps tool stable. The torque and rotation create a cutting force. The CNC program defines how fast the spindle spins (RPM), how deep the tool cuts, and how fast the tool moves across material (feed rate).

The spindle speed and torque matter a lot. For soft materials like aluminum or plastic, high speed and low torque work best. For hard metals like stainless steel, lower speed but high torque may be needed. The spindle must adjust quickly. The machine controller chooses right speed per material and cutting tool.

Good spindles also minimize vibration. Vibration can cause poor surface finish, wrong dimensions, or even break tools. Bearings and rigid structure keep wobble low. Cooling and lubrication help maintain stable temperature. That avoids expansion that could spoil precision.

A well-designed spindle also supports automatic tool changes. The machine may switch from a drill to a mill bit without stopping production. The spindle releases one tool and clamps the next. The tool holder mechanism must be accurate and reliable. That ensures repeatability across many parts.

In factories like mine, these actions repeat hundreds of times a day. A stable spindle means parts hold tight tolerances. It means less scrap. It means better output.

Why is the spindle important in CNC machining?

A CNC spindle is like the heart of the machine. If it falters, precision fails.

The spindle’s quality determines accuracy, surface finish, repeatability, and the ability to cut different materials under various loads.

The spindle directly affects key outcomes:

The spindle affects key performance aspects

- Accuracy: Any wobble or imbalance in the spindle transfers into the part. That ruins precision.

- Surface finish: Stable rotation and proper speed reduce chatter, leaving smooth surfaces.

- Material versatility: With the right speed and torque, you can cut soft plastics or hard metals alike.

- Throughput and consistency: Reliable spindles maintain speed and precision over many parts, ensuring minimal variation.

- Tool life: Proper spindle speed and smooth rotation extend the life of cutting tools, reducing costs and downtime.

Even small deviations matter when working with tight tolerances. In many modern industries, parts must match within 0.01 mm or tighter. Slight spindle inaccuracy can spoil a whole batch.

The spindle also helps reduce human error. Manual machines depend on operator skill. Even skilled machinists cannot match the consistency of a good spindle over hundreds or thousands of parts. CNC spindles do not tire and do not drift over time.

Because of this, spindle choice and maintenance become as important as tool selection. Poor maintenance or a worn-out spindle leads to defects, waste, and wasted time. A good spindle makes the difference between a profitable run and a costly failure.

Which types of spindles are used in CNC?

Not all spindles are the same. Machines use different types depending on the task.

CNC machines use several spindle types — each with strengths: belt or gear‑driven, direct‑drive, high‑frequency, or specially cooled spindles.

Here are common spindle types and how they differ.

Common CNC spindle types

| Spindle Type | Description | Typical Use |

|---|---|---|

| Belt‑driven / Gear‑driven | Motor drives spindle via belt or gear train | General machining, lower cost, moderate speed |

| Direct‑drive | Motor is directly connected to spindle shaft | Higher precision, less vibration, long life |

| High‑frequency spindle | Uses special motor to reach very high RPM (e.g. 10,000–30,000+) | High‑speed milling on plastics, aluminum, soft metals |

| Water‑ or oil‑cooled spindle | Spindle includes cooling system to manage heat | Long runs, heavy metal cutting, high‑speed operations |

| Torque‑optimized low‑speed spindle | Delivers high torque at low RPM | Hard metals, deep cuts, heavy‑duty machining |

How these spindles compare

| Feature / Spindle Type | Belt/Gear | Direct‑drive | High‑Freq | Cooled | Low‑Speed Torque |

|---|---|---|---|---|---|

| Precision | Moderate | High | High | High | High |

| Max RPM | ~6,000 | ~8,000 | 10,000+ | Depends | ~3,000 |

| Vibration | Moderate | Low | Low | Low | Low |

| Best for | General use | Fine parts, steel, aluminum | Soft metals, detailed work | Heavy duty, long runs | Hard metals, deep cuts |

Each type has trade‑offs. Belt‑driven spindles cost less. They handle standard jobs fine. But they may have some vibration and less long‑term consistency. Direct‑drive spindles give better stability. They work well for precision parts. High‑frequency spindles excel at fast, shallow cuts in soft materials. Cooled spindles handle long operations or heavy metal cutting without overheating. Low‑speed torque spindles give muscle for deep cuts or hard materials.

When selecting a spindle, I consider: what material, what part geometry, what finish, and what volume. For simple aluminum frame cuts, a high‑frequency spindle may work great. For heavy steel parts with deep pockets, a cooled, torque‑optimized spindle may be better. Choice affects tool wear, part quality, cycle time, and cost.

Machine builders design their CNC centers with different spindle types. Some machines even allow swapping spindles depending on the job. That gives maximum flexibility.

Where are CNC spindles applied?

CNC spindles are everywhere manufacturing happens. From small workshops to large factories.

CNC spindles power tools in industries like automotive, aerospace, medical devices, construction, electronics, and custom metal fabrication.

Here are common application fields and how the spindles help.

Industrial applications of CNC spindles

- Automotive industry: Making engine blocks, transmission parts, brackets, custom components. Spindles cut metal with precision for durability and performance.

- Aerospace: Producing lightweight but strong parts from aluminum or titanium. Precision and surface finish are critical.

- Medical device manufacturing: Creating implants, surgical tools, or custom instruments where tolerances and finish are strict.

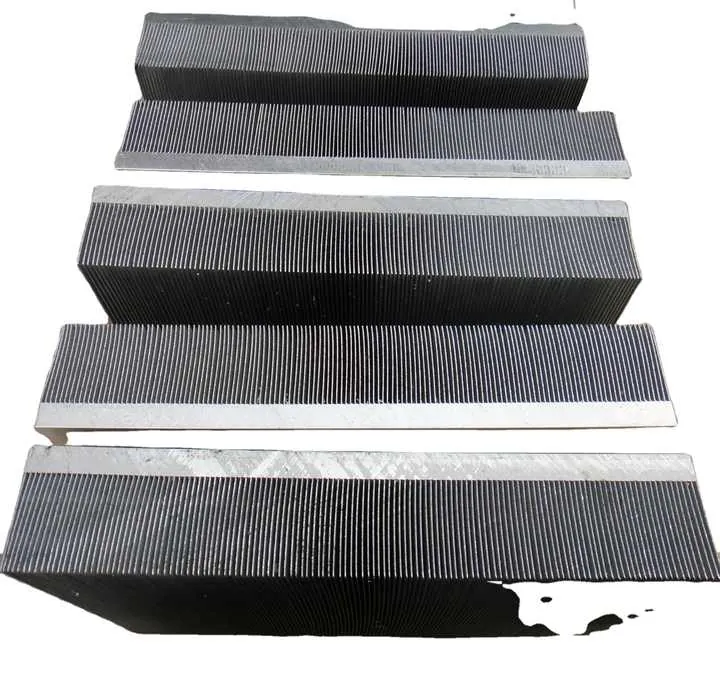

- Construction and architecture: Cutting aluminum profiles, frames, custom metal parts for facades or structures.

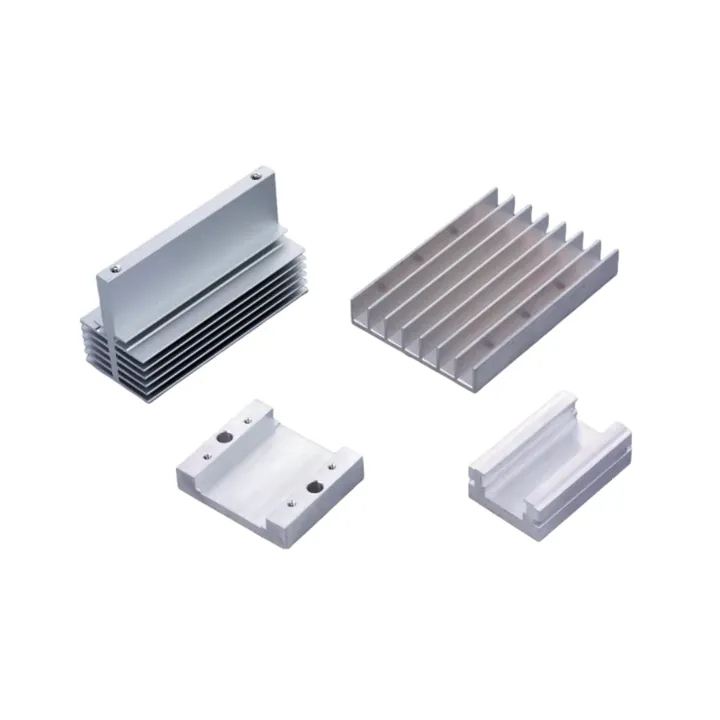

- Electronics and tech hardware: Machining housings, heat sinks, frames, connectors — often from aluminum or special alloys.

- Custom fabrication and prototyping: One‑off parts or small batches. Spindles allow fast turnaround without building molds or special tooling.

- Tool & die making, mold production: Spindles mill complex cavities, shape dies, and make molds for casting or injection.

In a company that makes aluminum profiles for windows, solar frames, or lighting housings, CNC spindles bring big advantages. The spindle can cut aluminum accurately, with clean edges and consistent profiles.

Even small workshops use CNC machines with simple belt‑driven spindles. They serve local clients who need custom parts quickly and cheaply. Larger factories invest in high‑frequency or cooled spindles. They need high throughput and long tool life to meet big orders.

In global supply chains, a company in China can produce parts and export to Europe, America, or Africa. The spindle performance ensures that parts meet precise international standards. That builds trust with clients and improves competitiveness.

When spindle choice matters most

Spindle choice matters when:

- Parts require tight tolerances (e.g. aerospace, medical)

- Materials are hard or abrasive (e.g. stainless steel, titanium)

- Runs are long or high volume (e.g. automotive, construction)

- Surface finish and part consistency are critical

In those cases, a bare‑bones spindle won’t work. You need direct‑drive, cooled, or torque‑optimized spindles. That ensures quality, consistency, and efficiency.

Using right spindles also reduces waste. Fewer defective parts. Less tool breakage. Lower overall cost per part. That matters when orders run into thousands or tens of thousands.

Conclusion

A CNC spindle is the cornerstone of machining precision and efficiency. It spins the tool, controls speed and torque, and delivers the stability needed for exact cuts. Knowing how spindles work and picking the right type helps ensure parts meet tight specs, run smoothly, and keep costs down. Spindles power modern manufacturing quietly but critically.