When precision becomes the deal-breaker, traditional workbenches fall short. That’s when CNC tables take the lead. But what exactly are they?

A CNC table is a flat platform that holds and moves materials during computer-controlled machining processes, allowing for accurate, repeatable, and complex operations across multiple industries.

Without this essential foundation, CNC machines would lose accuracy, speed, and efficiency. Let’s explore how these machines actually rely on their tables more than most realize.

How does a CNC table work?

It’s easy to think the machine does all the work. But without a steady base, even the best machine can’t deliver.

A CNC table works by securely holding workpieces and allowing precise movement under the toolhead, either by moving the table or coordinating with tool movement in X, Y, and Z axes.

A CNC table is typically made from heavy-duty steel or aluminum. It’s designed not to flex, even under intense cutting forces. This stiffness keeps materials stable and prevents vibration, which is key to maintaining precision.

Movement Mechanism

Most CNC tables integrate with stepper motors or servo motors. These motors are controlled by software, interpreting G-code commands. The commands tell the machine how far to move in each direction and how fast.

| Axis | Direction | Function |

|---|---|---|

| X | Left-Right | Moves the tool or table horizontally |

| Y | Front-Back | Adds a second horizontal dimension |

| Z | Up-Down | Controls the depth of the cut |

Some advanced tables can also rotate (A, B axes), allowing for multi-sided machining without repositioning the material.

Workholding Features

CNC tables often have T-slots, vacuum systems, or magnetic plates to hold materials in place. Clamps or fixtures are added to ensure nothing moves mid-operation.

- T-slot tables: These have grooves where clamps or vises are mounted.

- Vacuum tables: Use suction to keep flat sheets in place.

- Modular tables: Feature flexible workholding for custom parts.

Software & Automation

The table doesn’t work alone. CAD/CAM software determines the toolpath, and the machine follows this map. Feedback systems (like encoders) check if the table reaches the correct location and adjust if needed.

In short, the CNC table is more than a platform. It's an active player in achieving micron-level precision, by perfectly synchronizing with machine movement.

Why is a CNC table important in machining?

Precision is everything. Without a solid base, even the most advanced tool becomes unreliable.

A CNC table is critical because it ensures material stability, supports multi-axis movement, and maintains consistent accuracy during high-speed or complex machining tasks.

Think of the CNC table as the stage of a play. Without a flat, sturdy stage, the actors can't perform well. Similarly, the CNC machine relies on the table to deliver exact positioning and steady support.

Importance in Precision Machining

When tolerances are tight—often within microns—any vibration or movement can ruin the part. A poorly aligned table can shift the entire toolpath.

- Tight tolerances: Aerospace, medical, and automotive components demand precision.

- Surface quality: Table stability directly affects the smoothness of the cut.

Enhanced Efficiency

A good CNC table reduces setup time. You can fixture multiple parts at once, automate part loading, or machine large sheets without realignment. This increases productivity and reduces error.

| Feature | Benefit |

|---|---|

| Multiple part setup | Batch processing without resets |

| Integrated sensors | Real-time position correction |

| Modular surface | Faster changeovers between jobs |

Material Flexibility

Whether it's aluminum extrusion, plastic, wood, or steel, a CNC table can be adapted to hold different materials securely. Some models even switch between vacuum hold and mechanical clamping for diverse production runs.

The more reliable your table, the less risk of scrap parts or tool damage.

Which tasks require a CNC table?

Some processes can’t afford even a fraction of a millimeter in error. For those, the CNC table is non-negotiable.

Tasks that require a CNC table include milling, engraving, cutting, drilling, routing, and 3D contouring—especially when parts must meet tight specifications repeatedly.

Common Machining Tasks

Here’s a breakdown of where CNC tables prove essential:

| Task | Description | Table Function |

|---|---|---|

| Milling | Removes material with rotating cutters | Supports material against tool |

| Drilling | Makes precise holes | Aligns parts with drill position |

| Routing | Shapes soft materials like wood or plastic | Holds sheet material steady |

| Engraving | Adds text/design to metal or plastic | Maintains exact position |

| Plasma Cutting | Cuts metals using plasma torch | Grounds and stabilizes sheet metal |

Industries and Applications

- Aerospace: Wing components, turbine blades, landing gear housings

- Automotive: Engine blocks, chassis parts, suspension components

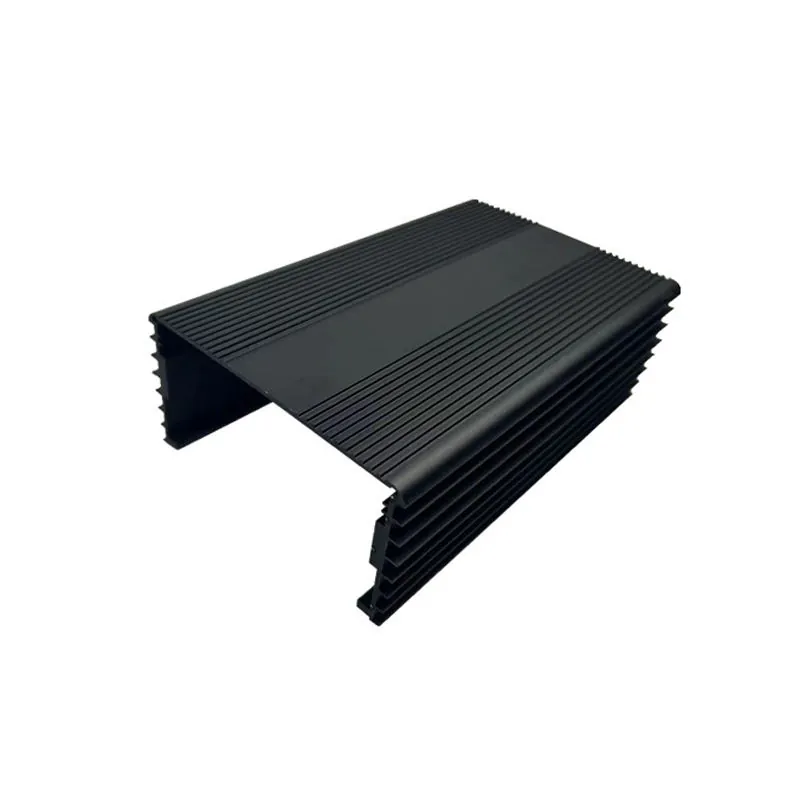

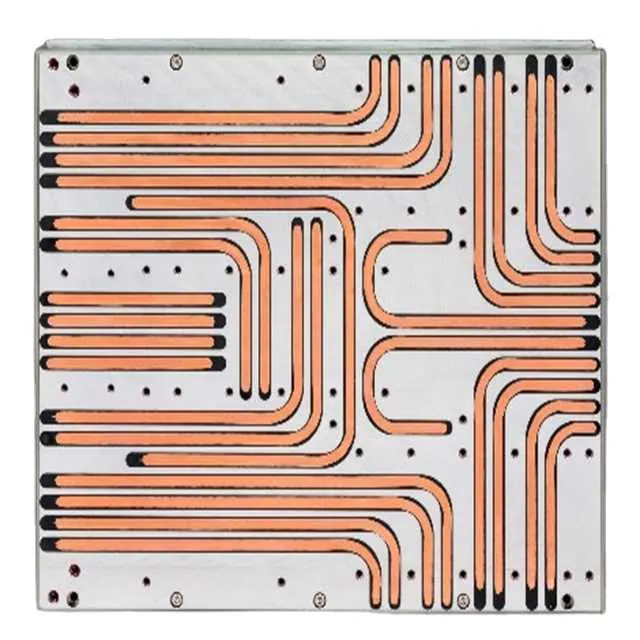

- Electronics: Heat sinks, enclosures, control panels

- Furniture: Wooden parts with complex curves and joints

CNC Tables for Prototyping

When building prototypes, dimensions often change. CNC tables allow for easy re-clamping and adjusting part positions without rebuilding the entire setup.

- Flexible fixture systems

- Quick material swap-outs

- Repeatable operations for batch testing

Whether the goal is to cut, drill, or contour, the CNC table ensures each operation starts from a reliable baseline.

Where are CNC tables used?

Anywhere that values speed, accuracy, and repeatability. And that includes more places than people think.

CNC tables are used in workshops, factories, R&D centers, and specialized industries such as aerospace, automotive, furniture making, electronics, and heavy machinery.

From Small Shops to Global Manufacturing

CNC tables are found everywhere—from small-scale fabricators to mass production plants.

1. Workshops and Job Shops

Small manufacturers often use compact CNC tables for short-run jobs or custom parts. They value easy setup and quick turnarounds.

2. Factories and Mass Production Lines

Large CNC tables handle multiple parts in a single setup. Robotic loaders and conveyors are often integrated for non-stop production.

3. Laboratories and R&D Centers

Prototypes demand fast, repeatable machining. CNC tables help researchers test new shapes and materials quickly.

Regional Adoption

Different regions use CNC tables in different ways:

| Region | Common Use Case |

|---|---|

| North America | Automotive and aerospace prototyping |

| Europe | Precision machinery and medical devices |

| Asia | Consumer electronics and tool making |

| Middle East | Large-format aluminum cutting for façades |

Key Considerations by Industry

Every application has unique needs:

- Construction: Large CNC tables for aluminum extrusions in window frames

- Solar Energy: Panel frame cutting and drilling

- Lighting Industry: Extruded housing fabrication

- Furniture: Complex 3D wood carving

The common theme across all industries is this: without a stable CNC table, you compromise speed, accuracy, and part quality.

Conclusion

A CNC table is more than a platform—it’s the backbone of modern machining. It keeps workpieces secure, synchronizes with machines, and makes complex tasks possible. From single prototypes to mass production, a CNC table makes precision repeatable.