Are you struggling to understand how power gets from an engine to the machine it drives? A transmission shaft is the key link—and if it’s not designed right, everything else suffers.

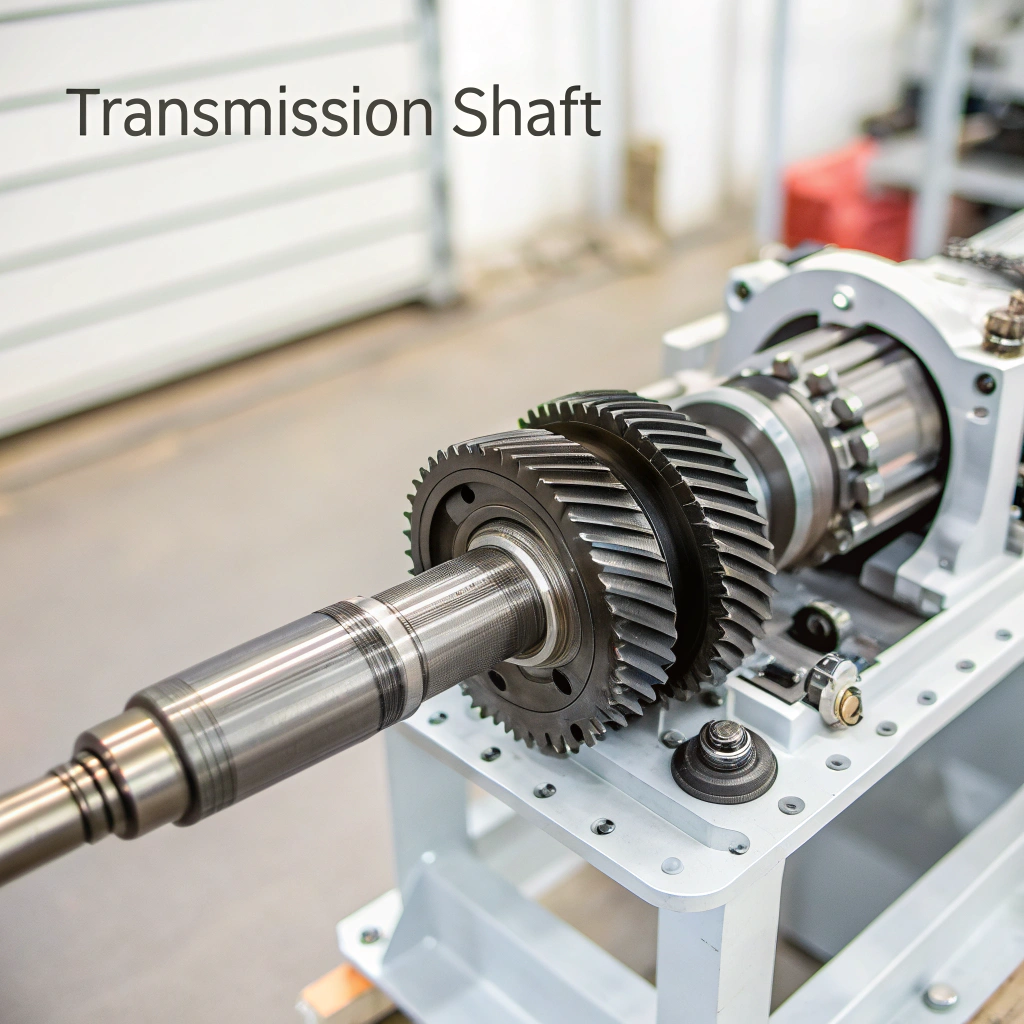

A transmission shaft is a rotating machine element—typically a circular bar—that transfers torque and rotational motion from a power source to a driven machine.

Let’s dig deeper into what exactly a transmission shaft is, what makes it so important, how we design and manufacture it, and what future trends are shaping its evolution.

What is a transmission shaft?

Picture this: a machine spinning, loads of torque flying through invisible metal—what makes it all happen? The transmission shaft steps up.

The transmission shaft connects the power‑producing part of a machine to the part that uses that power, transmitting torque and motion.

In mechanical engineering, the term “shaft” generally refers to a rotating member used to transmit power from one part of a machine (or from a prime mover) to another part.

A transmission shaft, more specifically, is a shaft used between the source of power (say a motor or engine) and the machine or device that absorbs the power (such as a gearbox, pump, or wheel).

Some key characteristics:

- It is usually circular in cross‑section (solid or sometimes hollow) because circular shapes give good resistance to torsion and bending.

- It must transmit torque (rotational force), as well as sometimes moments caused by attached gears, pulleys, or other loads.

- It must resist bending loads (due to weights or forces applied off‑axis) and sometimes axial loads (when the shaft is pushed or pulled along its axis) as well.

Let me illustrate with an example: In an automotive manual transmission, we typically see an input shaft (connected to the engine), a counter shaft, and an output shaft. These are examples of transmission shafts performing that link between engine power and wheels.

In summary, the transmission shaft is a foundational element in many power‑transmission systems. Without a correctly designed shaft, power might be lost to deformation, vibration, or failure.

What are the benefits of transmission shafts?

If you’ve ever felt frustrated by inefficient machines, you’ll appreciate that a well‑designed shaft can make all the difference—saving energy, reducing downtime, and improving performance.

A transmission shaft provides reliable power transfer, supports rotating elements, maintains alignment, resists loads and vibrations, and helps achieve efficient machine operation.

When I talk about benefits, I’m referring to the value a well‑engineered transmission shaft adds to a system. I will break down the major advantages and then look at some quantitative/qualitative aspects of each.

1. Efficient power transfer

A transmission shaft enables efficient transmission of torque from the source to the driven component. If the shaft is rigid, minimally deflecting, and properly aligned, less energy is lost. This means higher overall mechanical efficiency.

2. Structural support and alignment

The shaft often supports rotating elements such as gears, pulleys, flywheels, or hubs. It establishes the axis of rotation, ensures the moving parts are correctly aligned, and helps maintain the geometry of the rotating system.

3. Handling combined loads

Many systems impose combined loads on the shaft—torsional, bending, and sometimes axial loads. A well‑designed shaft handles these in a balanced way.

| Load Type | Benefit of proper shaft design |

|---|---|

| Torsional (torque) | Ensures torque is transferred without excessive twist |

| Bending | Minimises shaft deflection, misalignment, vibration |

| Axial | Avoids failure due to compression/tension |

4. Durability and service life

Proper material, surface finish, hardness, and geometry ensure a transmission shaft will endure cyclic loads and operational stresses over long service life.

5. Versatility in applications

Transmission shafts are used in automotive, aerospace, industrial machinery, power generation, pumps, gearboxes, etc. Their role is consistent but they adapt well to different needs.

In short, the benefits of transmission shafts are both practical (efficient torque transfer, reliable operation) and economic (longer life, less maintenance, lower energy losses).

How to design and manufacture transmission shafts?

If you’ve ever wondered why some machines last ten years and others fail in months, the answer often lies in how the shaft was designed and built.

Designing a transmission shaft involves calculating torque and loads, selecting material and geometry, considering fatigue and stress concentrations, then manufacturing with correct tolerances and surface treatments.

Let’s walk through the design and manufacture of a transmission shaft in more detail.

Step 1: Define requirements and loads

- Power and speed define torque.

- Gear/pulley attachments impose forces.

- Length and geometry affect bending and deflection.

- Duty cycle/environment impacts fatigue and corrosion design.

Step 2: Material selection

| Material | Strengths | Typical Use |

|---|---|---|

| Medium carbon steel | Cost‑effective, machinable | General machinery |

| Alloy steel | High strength, fatigue resistant | Heavy duty use |

| Stainless / special alloy | Corrosion resistant | Food, marine, chemicals |

| Hollow/composite | Lower weight, dynamic speed | Aerospace, racing |

Step 3: Geometry and stress calculations

- Torsional stress: ( \tau = T r / J )

- Bending stress: ( \sigma = M r / I )

- Combined stress: consider maximum shear theory

- Critical speed: avoid resonance

- Stress concentrations: reduce with fillets and better finishing

Step 4: Manufacturing process

- Forming/machining: hot rolled, turned, ground

- Features: keyways, splines, shoulders

- Heat treatment: induction hardening, nitriding

- Balancing: essential for high‑speed shafts

- Inspection: dimensional, hardness, NDT

Step 5: Assembly and support

- Proper bearings and couplings ensure alignment and reduce additional loads.

Step 6: Documentation

- Certificates, reports, test records important for traceability

| Stage | Key tasks | Important outputs |

|---|---|---|

| Requirements | Power, speed, loads | Torque, rpm, load data |

| Material selection | Mechanical + cost balance | Material grade + treatment |

| Geometry & stress | Stress analysis + fatigue check | Diameter, shape, tolerances |

| Manufacturing | Precision machining + finishing | Final shaft to spec |

| Assembly & support | Alignments, bearings, lubrication | Stable operation |

| Quality & docs | Inspection + traceability | Documentation |

What are the future trends in shaft engineering?

Technology never stands still—and even something as “simple” as a shaft is being transformed by new materials, manufacturing methods and smarter design.

Emerging trends in transmission shaft engineering include lightweight composites, advanced surface treatments/coatings, additive manufacturing, and meta‑material or vibration‑tunable shafts.

Let’s explore what’s next for shaft engineering:

Composite and hybrid materials

Carbon fiber reinforced shafts are lightweight but strong. Perfect for aerospace or auto. Aluminium hybrids are now being explored too.

Meta‑materials and vibration tuning

New shaft systems actively dampen vibration through “band gaps.” They allow longer life, smoother function, and less maintenance.

Additive manufacturing

More complex internal shaft geometries are now possible: hollow lattice shafts, internal damping layers, or sensors.

Surface treatments

Advanced coatings (DLC, ceramic) and ion‑nitriding extend fatigue life. Embedded sensors monitor shaft health in real time.

Sustainability

Designing with full lifecycle in mind: recyclability, less mass, longer wear, and smart monitoring.

Simulation-driven design

FEA tools allow more refined stress distribution and weight optimization, especially for custom applications.

| Trend | Key change | Implication for business |

|---|---|---|

| Composite / hybrid shafts | Lighter weight, high strength | New material skills, testing, partnerships |

| Vibration/meta‑material shafts | Tunable dynamics, less maintenance | Added complexity but premium offering |

| Additive / complex geometry | Internal structures, lightweight | New manufacturing routes, design‑for‑AM |

| Surface/coating/smart sensors | Enhanced life, monitoring | Value‑add finishing, IoT integration |

| Sustainability focus | Lifecycle thinking, recyclability | Marketing strength, compliance advantage |

| Digital/ simulation‑driven | Optimised designs, customised shafts | Early engagement, design services |

Conclusion

From defining what a transmission shaft is, exploring its benefits, diving into how to design and manufacture it, and looking ahead to future trends, transmission shafts are more than just simple rods. They are strategic components in power‑transmission systems. As I move forward, I’ll keep an eye on how materials, manufacturing and smart technologies converge in shaft engineering—and I hope you’ll do the same.