When it comes to achieving tight tolerances on flat metal parts, many shops struggle with efficiency, consistency, and surface finish. Traditional methods are slow and often inconsistent.

Blanchard grinding is a high-powered rotary surface grinding technique that creates precise, flat finishes on metal parts with speed and accuracy.

If you're working with metal parts that need to be flat, square, and parallel—Blanchard grinding could save you time and money. Let me walk you through what it is, why it matters, and how you can use it in real-world applications.

What is Blanchard grinding?

Many fabrication shops fight with uneven surfaces and inefficient milling when working with large metal pieces. Warped sheets, inconsistent tolerances, and slow finishing all increase production time.

Blanchard grinding is a rotary surface grinding method that removes material quickly from one side of a workpiece using a large vertical spindle and a magnetic chuck.

Blanchard grinding was named after the Blanchard Machine Company, which developed the technology in the early 1900s. It’s commonly used to grind large, flat surfaces quickly and efficiently. The machine uses a magnetic chuck to hold the metal in place while a rotating grinding wheel removes material from the surface. This creates a smooth, even finish with minimal setup time.

How it works

Blanchard grinders are different from traditional precision grinders. Instead of grinding in a linear motion, they use a rotating magnetic chuck and a grinding wheel that spins in the opposite direction. This dual-rotation design increases material removal rates while maintaining flatness.

Here’s a basic comparison:

| Feature | Blanchard Grinding | Surface Grinding |

|---|---|---|

| Grinding Motion | Rotary | Linear |

| Material Removal | High | Medium to Low |

| Surface Pattern | Circular cross-hatch | Parallel scratch marks |

| Best For | Large flat parts | Smaller precision parts |

| Setup Time | Short | Long |

Blanchard grinding removes up to 0.030 inches of material per pass, making it ideal for rough stock removal and flattening thicker metal plates before precision machining.

What are the benefits of Blanchard grinding?

Inconsistent flatness, long cycle times, and expensive finishing processes can slow down production and raise costs—especially in large-scale manufacturing.

Blanchard grinding is fast, cost-effective, and ideal for making thick metal plates flat and parallel before final machining.

Why choose Blanchard grinding?

Blanchard grinding has become a go-to solution for many industries like automotive, aerospace, heavy equipment, and construction. Here’s why:

1. High material removal rate

It can remove large amounts of material quickly. This is ideal when working with thick or warped steel, aluminum, or cast iron.

2. Precise flatness

Even though it’s considered a rough grinding process, Blanchard grinding can achieve flatness tolerances as tight as ±0.001" per foot, depending on part size and material.

3. Consistent finishes

The cross-hatched surface it produces improves coating or welding adhesion, making it great for parts that need additional surface treatments.

4. Cost savings

By combining rough and finish grinding into a single step, it reduces machine time, labor costs, and tool wear.

5. Versatility

Blanchard grinders handle large parts that wouldn’t fit on traditional precision grinders. Most machines can work on pieces up to 60 inches across.

Here's a quick look at common use cases:

| Industry | Common Parts | Why Blanchard Grinding? |

|---|---|---|

| Automotive | Engine blocks, transmission cases | Flat, parallel surfaces for assembly |

| Aerospace | Structural panels, brackets | High precision, fast turnaround |

| Construction | Steel plates, heavy frames | Durable finish, minimal distortion |

| Machine Shops | Weldments, bases, tooling plates | Prepares parts for CNC machining |

How to use Blanchard grinding for precision parts?

Precision parts usually require multiple processes—rough cutting, milling, grinding, and finishing. These take time and can lead to cumulative errors.

You can use Blanchard grinding to prepare a workpiece for precision machining by creating a flat, parallel surface that simplifies setup and reduces errors.

Step-by-step process

If I’m working on a CNC part that requires tight tolerances, my first step is often to Blanchard grind the raw stock. This gives me a reliable base for clamping and measuring. Here’s how it typically works:

Step 1: Material preparation

Start with oversized raw material. If the part is 12"x12"x1", I might begin with 12.25"x12.25"x1.25" to allow cleanup during grinding.

Step 2: Magnetic chuck setup

The part is mounted to the Blanchard grinder’s magnetic chuck. A coolant system keeps the part cool and prevents distortion.

Step 3: Grinding

The wheel spins as the table rotates. Multiple passes are made until the target thickness and flatness are reached.

Step 4: Inspection

A digital micrometer or dial indicator checks flatness. Parts can be squared up and marked for CNC work.

Pro tips for better precision

- Use two-sided grinding: Grinding both sides of a plate balances internal stress and prevents warping later.

- Leave minimal stock: Only remove what’s needed. Too much grinding can affect tolerances.

- Finish grind last: Do rough work first, then use Blanchard grinding as a final pass.

This method is great for tooling plates, spacer blocks, machine bases, and any flat surface that needs to mate with another part precisely.

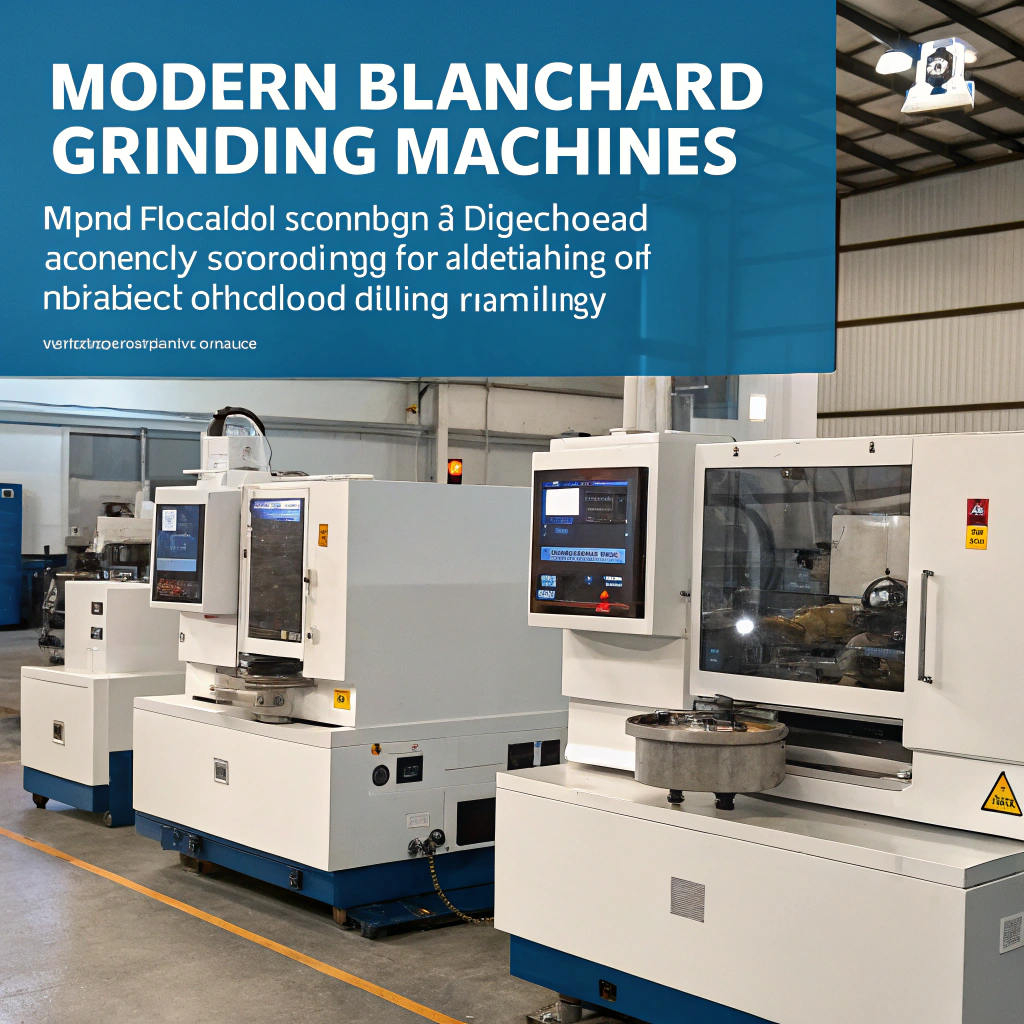

What are the latest developments in Blanchard grinding?

Traditional Blanchard grinders are known for power, but they haven’t always been known for precision or automation. That’s changing fast.

Recent developments in CNC controls, digital feedback, and grinding wheel technology have made Blanchard grinding more accurate and easier to automate.

Key innovations in the field

1. CNC integration

Some modern Blanchard grinders now include programmable controls. This means repeatable cycles, faster setups, and fewer human errors.

2. Improved wheel materials

New ceramic and diamond abrasive wheels improve cutting speed and lifespan. This lowers costs over time and boosts performance on hard materials like stainless steel or Inconel.

3. Digital measurement

Newer machines include automatic probing systems. These sensors check flatness in real time, reducing the need for manual inspections.

4. Environment-friendly coolants

Eco-safe coolants and mist reduction systems have made the process cleaner and more compliant with global environmental regulations.

5. Compact models for smaller parts

While Blanchard grinding is famous for large pieces, smaller machines now offer the same performance for high-mix, low-volume production lines.

What this means for your shop

If you’re in fabrication or precision machining, these upgrades can give you a competitive edge. Faster cycle times, better finishes, and less rework all translate to higher profitability.

Blanchard grinding isn’t just a roughing tool anymore—it’s a foundation for precise, repeatable quality.

Conclusion

Blanchard grinding helps simplify metalworking by making parts flat, fast, and ready for machining. It's powerful, flexible, and now more precise than ever thanks to modern upgrades.