Manual CNC operation can be slow, error-prone, and labor-intensive — especially in large-scale manufacturing. Setup delays and operator fatigue often limit production speed and consistency.

CNC automation combines computer-controlled machining with robotic systems, sensors, and software to streamline production, reduce labor, and boost precision and consistency.

Let’s explore how CNC automation works, why it's valuable, which tasks benefit most, and where it’s commonly applied in modern manufacturing.

How does CNC automation improve production?

Even the best CNC machine is limited if it waits for manual loading, tool changes, or inspections. Automation removes these delays and turns CNC into a 24/7 system.

CNC automation increases output, lowers error rates, and enables unattended operation — improving both productivity and profit margins.

Key Improvements from CNC Automation

-

Unattended Operation

With automation, machines can run overnight or during breaks — no human needed to load or check every part. -

Faster Setup

Automatic tool changers and zero-point systems reduce setup time between jobs, making small batches more efficient. -

Consistent Quality

Robots and sensors don't tire. They repeat tasks the same way every time, ensuring high part-to-part accuracy. -

Labor Savings

One technician can oversee several automated CNC cells, reducing the need for large teams on the shop floor. -

Data Integration

Automation ties into ERP and MES systems, letting businesses track production, maintenance, and quality in real-time.

CNC Automation Components

| Automation Feature | Function |

|---|---|

| Robotic Arm | Loads/unloads parts automatically |

| Automatic Tool Changer | Switches tools mid-process |

| Pallet System | Feeds multiple jobs to machine |

| Sensors/Probes | Measure, align, inspect parts |

| Conveyor System | Moves parts between stations |

These elements turn a CNC machine into a full production cell — ready for high-mix, low-volume, or continuous operation.

Why integrate automation in CNC?

Some manufacturers worry automation is only for big factories. But even small shops can benefit from efficiency, fewer errors, and better output tracking.

Integrating automation in CNC reduces costs, increases competitiveness, and handles labor shortages — all while improving reliability and output.

Key Reasons to Integrate CNC Automation

-

Reduce Labor Dependence

Skilled machinists are hard to find. Automation fills the gap and frees experts for higher-value tasks. -

Shorter Lead Times

Automated setups run faster and minimize downtime between parts — perfect for short-run jobs or urgent orders. -

Scalable Growth

A business with one automated cell can produce more than several manual machines. This supports growth without hiring a large team. -

Higher Machine Utilization

Most manual CNC machines run only during shifts. Automation runs machines around the clock. -

Improved Safety

Robots handle sharp tools, hot chips, or heavy parts — reducing risk to human workers.

Even small-scale automation (like a tool changer or part probe) brings major benefits over time. As needs grow, systems can be expanded or integrated into full lights-out manufacturing.

Which tasks benefit from CNC automation?

Not every task needs full automation, but certain repetitive or precision-demanding jobs get major boosts in speed and accuracy.

Tasks that involve repetitive cuts, part handling, tool changes, or inspection benefit most from CNC automation.

Table: Common Tasks Enhanced by CNC Automation

| Task | Automation Benefit |

|---|---|

| Part Loading/Unloading | Robots reduce idle time |

| Tool Changing | ATCs allow complex multi-tool jobs |

| In-Process Inspection | Probes measure and adjust mid-job |

| Material Handling | Conveyors or robots move parts safely |

| Small Batch Setup | Fast re-fixturing boosts flexibility |

| Engraving/Labeling | Done automatically, tracked by software |

Real-World Examples

-

Automated Tool Changing: A CNC mill with 30-tool carousel can switch between roughing and finishing without manual input — saving hours on complex parts.

-

Robotic Palletizing: In high-volume production, robotic arms load fresh stock and remove finished parts — keeping machines running non-stop.

-

Smart Probing: In aerospace or medical part manufacturing, automated probes verify tolerances during the cut — reducing scrap and rework.

These automation steps free operators to focus on programming, quality checks, or new job setups — improving shop efficiency across the board.

Where is CNC automation used?

CNC automation isn't just for big factories. It fits wherever repeatability, precision, and volume matter — from car parts to medical devices.

Industries using CNC automation include automotive, aerospace, electronics, medical, metalworking, and high-end woodworking.

Table: CNC Automation Applications by Industry

| Industry | Use Cases |

|---|---|

| Automotive | Engine blocks, transmission housings |

| Aerospace | Turbine blades, structural components |

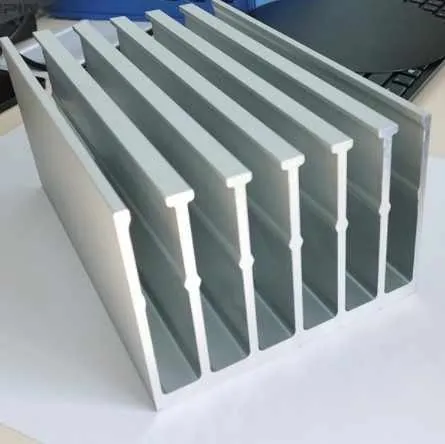

| Electronics | Heat sinks, enclosures, connectors |

| Medical | Surgical tools, orthopedic implants |

| Metal Fabrication | Complex metal frames, gears, valves |

| Furniture | Automated joinery, repetitive parts |

Where Else It's Expanding

- Education & Training Centers — teach smart manufacturing and Industry 4.0 concepts

- Job Shops — speed up production for short-run, high-mix jobs

- Prototyping Labs — test products faster with automated production and measurement

- Defense & Military — produce mission-critical parts with full traceability

Automation makes it easier for companies to meet modern manufacturing challenges — including labor shortages, demand spikes, and strict quality standards.

Conclusion

CNC automation combines machining power with intelligent systems to boost speed, reduce errors, and maximize uptime. Whether using robots, tool changers, or sensors, automation transforms CNC machines into efficient, self-sufficient production units. From aerospace to furniture making, CNC automation is now essential for quality, scalability, and staying competitive.