A simple mistake or slow process can break whole projects. A CNC control system cuts those risks fast.

A CNC control system is a computer‑based setup that directs machining tools to follow precise paths. It controls motion and operation so machines build parts exactly as programmed.

With precise direction of tools and machines, CNC systems keep production accurate and repeatable. That matters for quality, speed, and safety. Let’s look at how they work and why they matter.

How does a CNC control system operate?

Machines can cut wrongly if control fails. CNC control makes them follow exact commands so parts stay correct.

A CNC control system reads a program, interprets instructions, and sends signals to motors and drives to move tools exactly. It works like a conductor leading an orchestra of machine parts.

Below we explore step by step how the system reads code, turns it into movement, and ensures reliable machining.

A CNC control system starts with a code file. Usually this code is in a standard format called G‑code. The code tells the machine where to move, how fast to move, and what actions to do (like cut or drill). The controller is like a brain. It reads each line in the code and checks it. Then it creates a motion path. That path goes to motion planner inside the system. The motion planner divides big moves into many small steps. This ensures smooth motion and accurate tool path.

Then the controller sends signals to servos or stepper motors. Those motors move machine parts along axes (like X, Y, Z). If the machine has more axes (like 4th or 5th axis), the controller handles those too. The signals tell motors how far to go, how fast, and when to start or stop. The controller also monitors sensors and feedback devices, like encoders. Feedback helps ensure actual movement matches commanded movement. If there is difference, controller adjusts motor commands. This feedback loop keeps motion precise.

The control system also handles other parts of machining. It can control tool changes. It can run coolant or spindle speed. It can pause or stop under certain conditions. Some controllers allow manual commands or overrides. For example, operator can jog the tool or do manual positioning with hand wheel or panel controls. The controller mixes automatic moves from code with manual adjustments when needed.

A CNC controller often runs in real time. It repeats steps many times per second. This ensures smooth motion and accurate timing. Without real‑time control, motion could lag or overshoot. Real‑time control also helps coordinate multiple axes at once. That is important when the tool moves on curved paths or complex shapes.

The process flow is like:

- Load program

- Interpret commands

- Plan motion

- Send signals to motors and actuators

- Monitor feedback

- Adjust motion if needed

- Control auxiliary functions (tool change, spindle, coolant)

- Complete part

With that setup, CNC control system turns code into precise physical movement. That operation makes modern machining possible.

Why are CNC controllers essential for automation?

Manual machining can be slow, inaccurate, and inconsistent. Automation needs reliable control over machines.

CNC controllers let machines run with minimal supervision. They drive automation by ensuring parts are made the same way every time with high precision.

Without controllers, automation in machining would be nearly impossible. CNC provides repeatability, speed, and safety.

When building many parts, manual work can bring mistakes. Even skilled machinists can vary slightly. That might cause wasted material, scrap, or rework. CNC controllers solve that by giving exact instructions each time. Once you load a program, machine repeats same moves over and over. That ensures all parts match to design.

CNC control also boosts speed. Manual machining often needs human to watch, adjust, stop, measure, then continue. That takes time. CNC machines run continuously. They only stop when job finishes or when program ends. Also CNC can run at higher speeds, with faster tool motion, because controller handles timing precisely. That reduces cycle time per part and increases output.

Automation with CNC improves safety. Manual work can be risky. Operator uses tools close to cutting edges, hot chips, sharp bits. CNC keeps operator away from danger because machine runs automatically. Controller also monitors conditions. It can stop machine if something is wrong, like over‑load, too much vibration, or tool break. That reduces risk of accidents and damage.

CNC also supports complex parts. Some parts have curved surfaces, holes at strange angles, multiple axes. Manual work for such parts takes long time and cost more. CNC can handle complex geometry easily. Controller coordinates multiple axes simultaneously. It makes precise contours, intricate shapes, or repeated patterns. That power enables automation for advanced manufacturing.

Another key is flexibility. If design changes, you update program, then run new parts. No need to retrain worker or reset jigs. That makes production adaptive. For custom parts or small batches, CNC automation remains useful. Without CNC controller, changing designs means manual redrawing and setup. That costs time and effort.

In short, CNC controllers are the core of automated machining. They handle precision, repeatability, speed, safety, flexibility. They turn manual work into modern automated production.

Which components form a CNC control system?

Without certain parts a CNC system cannot work well. A few parts must work together.

A CNC control system includes a controller (computer), motion hardware (motors, drives), feedback devices (encoders), and interface elements like panel or screen. These parts coordinate to build accurate parts.

Below I list main components and how they fit together.

A typical CNC control system has several key components. Below is a table that shows each major part and its role:

| Component | Role / Function |

|---|---|

| Controller (CPU + software) | Reads program (G‑code, M‑code), interprets commands, plans motion |

| Motion drives (stepper or servo drives) | Provide power and control to motors that move machine axes |

| Motors (servo or stepper) | Move machine parts (axes, tool holders, tables) |

| Feedback devices (encoders, limit switches) | Monitor actual position and signal to controller for corrections |

| Human‑machine interface (panel, screen, keypad) | Allow operator to load program, start/stop job, monitor status |

| Auxiliary controls (spindle, coolant, tool changer) | Manage additional machine functions based on program commands |

Some CNC systems also include optional components, like:

- Software for CAD/CAM, which helps design part and generate CNC programs.

- Networking or data links, for fleet management or remote monitoring.

- Safety interlocks or guards, to meet safety standards.

How the components connect

The controller sits at center. It holds the program and logic. That logic sends commands to motion drives. Drives amplify signals and power motors. Motors move axes. After each move, feedback devices send back data to controller. Controller checks and corrects if needed. The operator uses interface to interact: load program, start job, or pause job. Auxiliary controls handle spindle, coolant, or tool change as needed.

Example workflow

When operator loads program through interface, controller begins reading commands. Controller tells drives to move motors. Motors move cutter along X, Y, Z axes. Encoders monitor position. Controller corrects errors. Spindle speed and coolant turn on. If tool change is required, auxiliary control manages it. After part finish, controller stops all systems. System waits for next job.

This structure lets CNC system be precise, reliable, and flexible.

Where is CNC control used in manufacturing?

Many industries shape metal or other materials. CNC control finds home in many of them.

CNC control is used in industries from automotive to aerospace, electronics to furniture. Anywhere machines need precision and repeat parts, CNC helps.

Below I show common uses, industries, and kinds of parts made with CNC.

Here is a table of industries, example parts made with CNC, and why CNC is used there:

| Industry / Sector | Example Parts or Products | Why CNC is Used |

|---|---|---|

| Automotive | Engine blocks, chassis parts, gears, brackets | Needs high precision, many identical parts, strong structures |

| Aerospace | Airframe components, turbine parts, structural frames | Tight tolerances, complex shapes, high strength materials |

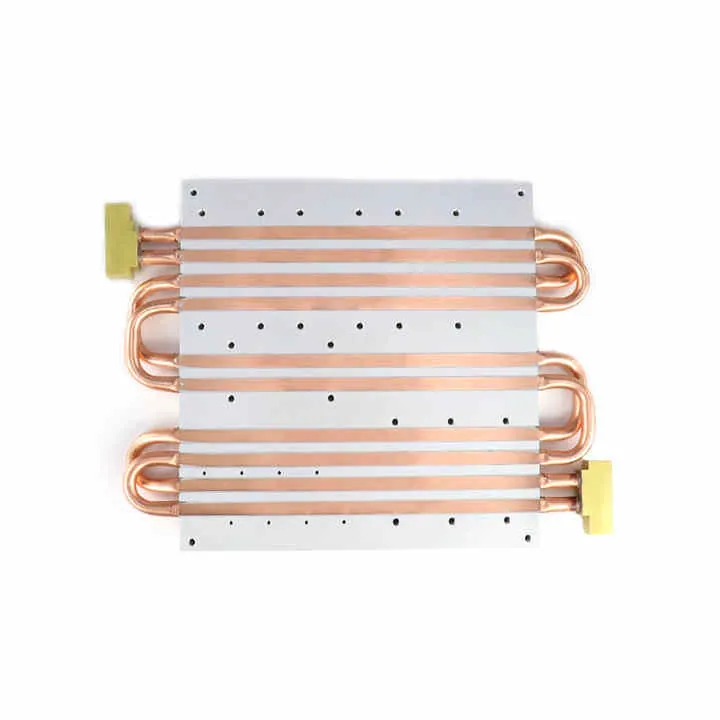

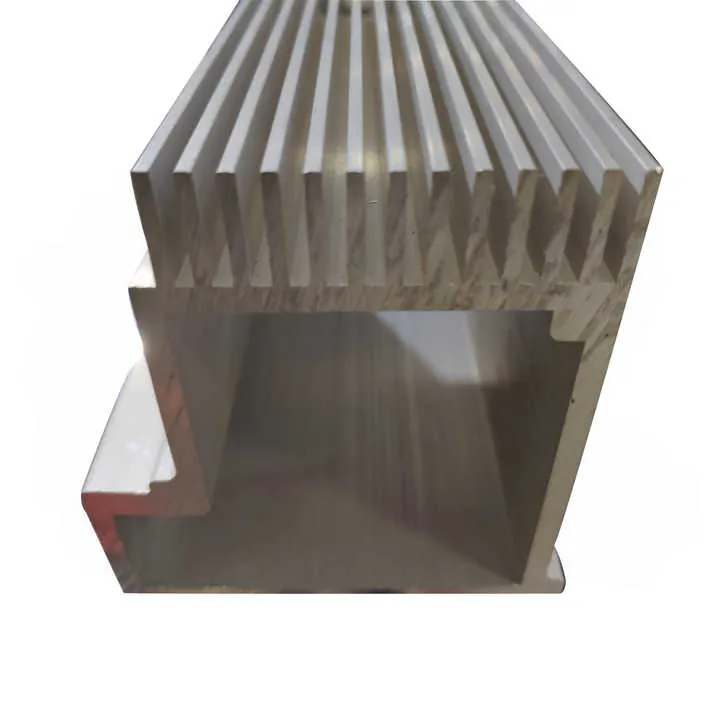

| Electronics | Housings, heat sinks, chassis for devices | Small size, precise holes, clean cuts |

| Furniture / Lighting / Building | Metal frames, lighting fixtures, railings, skirting | Custom sizes, repeat orders, surface finishes |

| Machinery / Tools | Machine frames, molds, tools, dies | Heavy material, accuracy, repeatability |

| Solar / Renewable Energy | Solar panel frames, mounting structures | Large volume, corrosion‑resistant, consistent |

These examples show CNC covers wide area. CNC handles both heavy metal and fine, light material. CNC works for single custom piece or mass production.

Industries use CNC because it gives reliable quality and repeatability. For automotive, parts must fit perfectly. CNC ensures that. For aerospace, safety matters. CNC delivers the needed precision. For electronics, parts are small but need exact size and clean finish. CNC can do that. For furniture or building products, many items may look similar but need exact dimensions. CNC supports batch work. For solar energy frames or lighting fixtures, manufacturers need many identical pieces. CNC ensures consistency and speed.

Special uses and benefits

- Custom parts: If a customer orders a custom piece, user can design in CAD, then use CNC to produce exactly as drawn.

- Small batch production: For small orders, CNC avoids cost of jigs or molds, and still gives precision.

- Complex geometry: Curved surfaces, angled holes, multi‑axis parts can be done with CNC.

- Mixed materials: CNC can cut aluminum, steel, plastics, composites. That supports versatile production.

- Quick changeover: Switching from one part to another only needs changing program. Mechanical setup stays minimal.

Because of these benefits, CNC control is key in modern manufacturing. Automation, precision, flexibility make CNC central to many factories.

Conclusion

CNC control systems turn digital design into real parts with precision, speed, and reliability. Their operation, core components, and broad uses show they form backbone of modern manufacturing automation.