CNC equipment is reshaping the way parts are made, but many still don’t know what it really means. The term sounds technical, but its impact is everywhere.

CNC equipment refers to computer-controlled machines that automate the cutting, shaping, and manufacturing of materials into precise parts. These systems improve accuracy, reduce errors, and allow repeatable production with high efficiency.

In the past, everything had to be cut or drilled by hand. Now, CNC machines do the same tasks with much higher precision, faster speed, and more consistent results. This shift is changing industries from automotive to aerospace. Let's explore more below.

What types of CNC equipment are there?

CNC machines sound like one tool. But in fact, there are many types, each serving different functions depending on the task or material.

The most common types of CNC equipment include milling machines, lathes, routers, plasma cutters, and grinders. Each machine operates on the same principle—computer-guided movement—but their tools and applications vary widely.

Main Categories of CNC Machines

CNC machines can be grouped by what kind of motion they use and what tools they work with. Here are the major types:

| CNC Machine Type | Main Function | Common Materials |

|---|---|---|

| CNC Milling Machine | Cuts and shapes using rotating tools | Metal, plastic |

| CNC Lathe | Spins material to shape it | Metal, wood |

| CNC Router | Carves soft materials | Wood, plastic, foam |

| CNC Plasma Cutter | Uses plasma torch to cut | Steel, aluminum |

| CNC Laser Cutter | Cuts using laser beam | Plastic, metal, wood |

| CNC EDM | Removes material with electric discharge | Hard metals |

| CNC Grinder | Finishes with precision grinding | Metal |

Each of these machines works under a pre-programmed set of instructions (G-code). The machine then follows these instructions without manual input. Some machines combine several tools in one unit, called multi-axis or multi-function CNC machines.

Choosing the Right CNC Tool

Different tasks require different machines. For example:

- CNC routers are good for cutting soft materials like wood panels or foam boards.

- CNC milling machines are used in industries that need complex, 3D shapes in metal.

- CNC lathes are excellent for creating round parts, like shafts or pipes.

- Laser cutters and plasma cutters offer clean edges, especially for thin sheets.

The selection depends on budget, production volume, material type, and the level of precision required.

Why is CNC equipment essential in modern manufacturing?

Manual machining is too slow, inconsistent, and labor-intensive for today's manufacturing needs. The demand for high precision and fast turnaround makes traditional methods hard to sustain.

CNC equipment ensures consistent quality, high efficiency, and precise control, which are critical for meeting modern production standards. It also reduces human error and allows automation of complex tasks.

Advantages of CNC in Manufacturing

CNC equipment helps businesses in many ways:

1. Consistency and Accuracy

Once a program is written, the CNC machine can make thousands of identical parts without error. This is important for parts that must fit together perfectly, such as engine components.

2. Reduced Waste

Less error means less waste. Materials like aluminum, titanium, or carbon fiber are expensive. CNC machines help cut exactly what is needed, minimizing scraps.

3. Faster Production

A CNC machine runs day and night without breaks. Once the setup is complete, production can continue with minimal human supervision.

4. Complex Designs Made Easy

Designs that would take hours by hand can be finished in minutes with a CNC machine. Curves, holes, slots, and 3D surfaces can all be programmed and executed automatically.

Real World Example

For example, in automotive parts manufacturing, a CNC milling machine can produce an aluminum gearbox housing with multiple drill holes and curves in under 20 minutes. Manually, this would take several hours and would still not achieve the same precision.

This kind of productivity is why factories around the world are switching to CNC-based systems. They're not just tools; they are the foundation of digital manufacturing.

Which industries rely on CNC equipment?

CNC machines are not limited to just one sector. They are a backbone in many different industries that require accurate, repeatable production.

Key industries that use CNC equipment include aerospace, automotive, electronics, medical, defense, and industrial manufacturing. These sectors depend on precision-made components with tight tolerances.

Where CNC is Used

Let’s break down some major fields and how they rely on CNC machines:

| Industry | CNC Application Examples |

|---|---|

| Aerospace | Engine parts, structural frames, precision housings |

| Automotive | Gear components, engine blocks, suspension parts |

| Medical Devices | Implants, surgical tools, diagnostic equipment parts |

| Electronics | Circuit boards, heat sinks, aluminum enclosures |

| Defense | Weapon parts, armor plates, vehicle structures |

| Manufacturing | Jigs, fixtures, dies, molds, custom metal parts |

Focus on Medical and Electronics

In the medical sector, CNC machines help produce implants like hip joints or dental crowns. These parts must fit perfectly and be made from biocompatible metals. CNC ensures both precision and cleanliness.

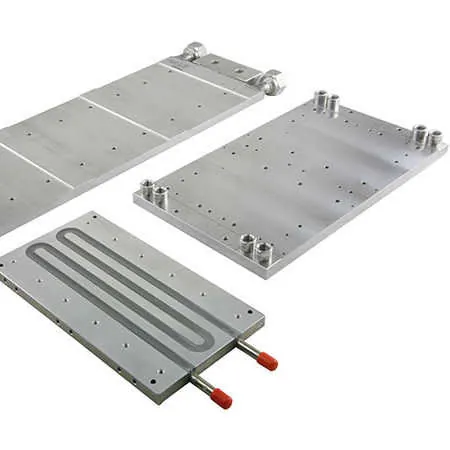

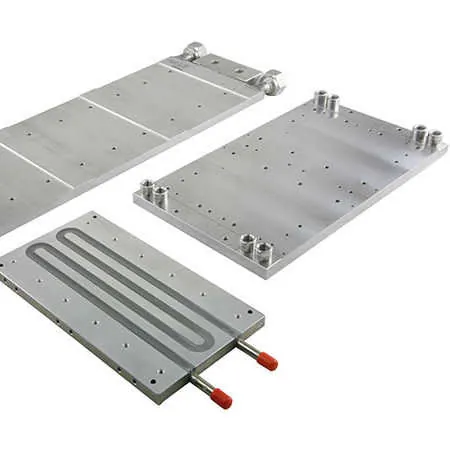

In electronics, CNC milling is used to make custom heat sinks from aluminum. These are vital for thermal management in communication systems, servers, or LED lights.

Growing Sectors

New industries like renewable energy and electric vehicles also rely heavily on CNC parts. For example:

- CNC cut aluminum plates are used in battery enclosures.

- Complex cooling structures for EV systems are made with CNC liquid cooling plates.

The more advanced a system is, the more it depends on parts that are accurate and reliable. This makes CNC tools an essential investment.

Where to buy CNC equipment?

Choosing the right CNC supplier is just as important as picking the right machine. With so many options worldwide, it can be hard to decide where to start.

You can buy CNC equipment from specialized manufacturers, online platforms, trade shows, or through industrial distributors. What matters most is matching your needs with the supplier’s capability, support, and certifications.

Key Buying Channels

Here are the main sources where companies buy CNC machines:

| Buying Source | Pros | Cons |

|---|---|---|

| Direct from Manufacturer | Full customization, lower cost | Longer lead time, language/cultural gap |

| Authorized Distributor | Local support, after-sale service | Higher price, limited customization |

| Industrial Platforms | Easy comparisons, fast quotes | Risk of fake listings, less detailed info |

| Trade Shows | Face-to-face demos, networking | Travel required, fewer options per show |

What to Check Before Buying

Before placing an order, consider these:

- Precision and specs: Does the machine meet your required tolerances?

- Software compatibility: Can it work with your CAD/CAM files?

- Support and training: Will the supplier provide help during setup?

- Certifications: Especially important if exporting to Europe, the US, or Japan.

For long-term use, a good CNC machine should come with:

- Spare parts availability

- Clear user manuals

- ISO or CE certification

- Test runs and performance reports

If you're sourcing internationally, it’s important to ask for sample production or at least videos showing the machine in real operation. Also, check lead times and logistics options.

Conclusion

CNC equipment is the backbone of today’s precision manufacturing. From simple cuts to complex systems, it enables fast, reliable, and scalable production across industries.