Modern manufacturing is changing fast. Customers demand high precision, faster delivery, and flexible production. But traditional methods often can't keep up.

CNC in machining means using computer control to run machines. This helps make metal and plastic parts with high accuracy and repeatability.

Many industries depend on CNC to meet quality and speed needs. Let’s explore how CNC works and why it matters so much today.

What role does CNC play in machining?

Traditional machining required skilled operators to manually cut, shape, or drill materials. It was time-consuming and prone to errors. This created waste and slowed production.

CNC, or Computer Numerical Control, automates machine operations using software and pre-programmed code. It replaces manual controls with digital precision.

CNC acts like the brain of the machine. It takes digital instructions, usually in the form of a G-code file, and tells the machine exactly how to move. These movements can be as simple as a straight cut or as complex as a 3D contour.

How CNC changes the machinist's role

With CNC, a machinist becomes more of a programmer and supervisor than a hands-on tool user. They load the code, set up the material, and let the machine handle the rest. This reduces labor cost and training time.

Machines that commonly use CNC

| Machine Type | CNC Function |

|---|---|

| CNC Lathe | Spins the workpiece while cutting tools shape it |

| CNC Milling Machine | Cuts shapes using rotating tools |

| CNC Router | Cuts soft materials like wood, plastic, foam |

| CNC EDM (Electrical Discharge Machine) | Cuts hard materials using electrical sparks |

CNC plays a key role by improving precision, lowering mistakes, and speeding up the whole production cycle. Without it, modern manufacturing would not meet today’s demand.

How does CNC improve machining efficiency?

Manual machining is slow and often inconsistent. Human hands can’t repeat the same motion a thousand times with perfect accuracy. This results in variations, rework, and delays.

CNC boosts efficiency by automating tasks, minimizing waste, and enabling 24/7 production with minimal supervision.

One CNC machine can do the work of several traditional machines. And it can switch between jobs by just loading a new program. This makes it easy to respond to new orders quickly.

Key ways CNC improves efficiency

1. Faster setup and changeovers

Changing from one part to another takes minutes. You just upload the next program. This reduces downtime between batches.

2. Consistency and repeatability

Once you dial in a program, every part comes out the same. No adjustments, no guesswork.

3. Unattended operation

CNC machines can run all night. With automatic tool changers and material feeders, some shops operate "lights-out" — no humans needed during off-hours.

4. Less scrap

Machines follow code exactly. Errors only happen if the program is wrong. This reduces the waste of expensive materials.

CNC and lean manufacturing

Many factories use lean methods to cut waste. CNC supports this by producing just what is needed, when it’s needed. It also supports JIT (Just-In-Time) production, helping companies stay flexible.

| CNC Efficiency Benefit | Result |

|---|---|

| Fast setup | Shorter lead times |

| Repeatable output | Lower inspection costs |

| Less manual work | Reduced labor costs |

| Run overnight | Higher machine utilization |

Overall, CNC turns time-consuming manual tasks into fast, automated processes. This helps factories respond faster, reduce costs, and stay competitive.

What types of machining processes are controlled by CNC?

Different CNC machines are designed for specific tasks. Each one follows the same principle: use computer instructions to guide cutting, drilling, or shaping.

CNC controls various machining processes including milling, turning, grinding, cutting, and even 3D printing.

Common types of CNC machining

CNC Milling

Milling uses rotating tools to remove material from a fixed block. CNC mills have 3, 4, or 5 axes, which lets them cut complex shapes.

CNC Turning (Lathe)

Turning spins the part while a cutting tool removes material. It’s used for round objects like rods, tubes, and bushings.

CNC Drilling

This process creates holes in a part. CNC drills are often part of a mill, allowing precise hole placement.

CNC Grinding

Grinding machines smooth surfaces using a rotating wheel. CNC ensures even pressure and fine finishes.

CNC Laser Cutting

This uses a laser beam to cut metal, plastic, or wood. It’s fast and leaves clean edges.

CNC Plasma Cutting

Similar to laser but uses ionized gas. It’s used for thicker materials.

CNC EDM

Electrical Discharge Machining uses sparks to erode material. It’s perfect for hard metals or complex molds.

CNC Waterjet Cutting

High-pressure water mixed with abrasive cuts almost anything. It’s good for materials that can’t take heat.

Specialty CNC processes

Some shops use CNC to control welding, robotic arms, and even additive manufacturing like 3D printing. The code stays the same: precise digital control over mechanical actions.

| CNC Process | Material Used | Typical Products |

|---|---|---|

| Milling | Aluminum, steel | Engine parts, brackets, molds |

| Turning | Brass, plastic | Shafts, bushings, connectors |

| EDM | Hardened steel | Dies, tools, injection mold cavities |

| Laser Cutting | Sheet metal | Signs, panels, machine enclosures |

CNC makes all these processes faster, more flexible, and more accurate. This helps manufacturers meet diverse needs with one technology platform.

Why is CNC machining important in manufacturing?

Manual methods cannot keep up with the demands of today’s customers. Global competition, shorter lead times, and rising quality expectations force companies to work smarter.

CNC machining matters because it delivers speed, quality, and precision at scale — things manual processes cannot achieve.

CNC is the foundation of modern manufacturing. It’s used in industries from aerospace to furniture. Without it, it would be hard to build consistent, affordable products at scale.

CNC and global supply chains

Factories use CNC to maintain consistent quality across regions. A part made in China can match one made in Germany — because the machine follows the same digital file.

CNC enables mass customization

Customers want custom products — but fast and cheap. CNC makes this possible by switching programs easily. You can make one part or a thousand, and all will match the design.

Impact on quality and safety

Manual mistakes can lead to part failure or safety hazards. CNC reduces this risk. Machines cut to exact tolerances, with no fatigue or distraction.

Sustainability benefits

CNC uses material more efficiently. Less scrap means fewer raw materials are needed. Plus, digital control allows better planning and leaner operations, which helps the environment.

Industries that rely heavily on CNC

| Industry | CNC Applications |

|---|---|

| Aerospace | Engine parts, structural components |

| Automotive | Frames, panels, gears |

| Medical | Surgical tools, implants |

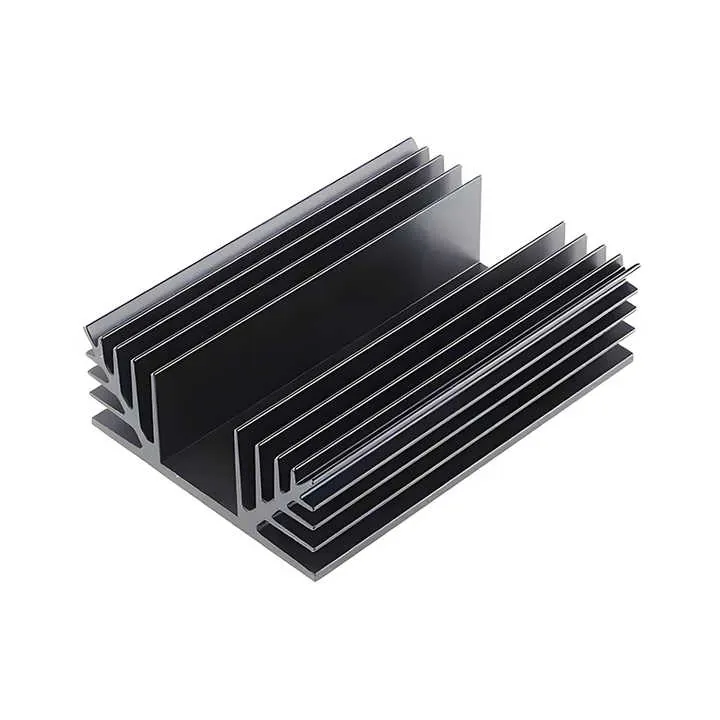

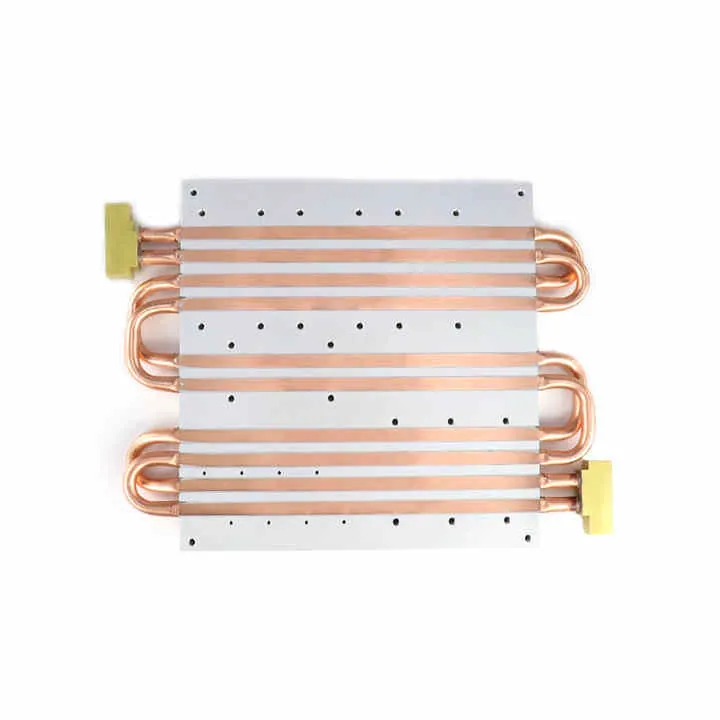

| Electronics | Housings, heat sinks |

| Furniture | Custom wood pieces, metal frames |

CNC is not just a tool. It’s the reason factories can deliver fast, accurate, and repeatable products. It supports innovation and keeps businesses competitive in a crowded global market.

Conclusion

CNC in machining replaces manual work with digital accuracy. It increases speed, reduces waste, and ensures high-quality production across industries. It’s the backbone of modern manufacturing.