Manufacturers often face problems like tool wear, long downtimes, or inconsistent quality. These issues slow down production and increase costs.

CNC intelligence uses smart sensors, data, and artificial intelligence to optimize machining performance, reduce waste, and improve precision.

By combining traditional CNC machining with real-time data analysis and automation, companies can now build faster, smarter, and more reliable production systems.

How does CNC intelligence improve machining?

Machining without real-time feedback can lead to errors, tool failure, or poor surface finish. Operators often react too late.

CNC intelligence improves machining by analyzing real-time data, adjusting cutting parameters, and predicting failures before they happen.

Modern CNC systems are equipped with smart sensors that monitor temperature, vibration, load, and tool condition. This data is fed into algorithms that can make automatic changes or alert the operator.

Key Functions of Intelligent CNC Systems

| Function | Benefit |

|---|---|

| Tool condition monitoring | Detects wear early, avoids failure |

| Adaptive control | Adjusts speed and feed in real time |

| Predictive maintenance | Prevents unexpected downtime |

| Quality monitoring | Reduces defects and rework |

Real-Time Optimization

When cutting aluminum or other materials, the machine can adjust cutting speed if vibration increases or temperature rises. This keeps the process stable and improves surface quality.

Reduced Scrap and Downtime

With better data, the machine avoids pushing tools past their limits. This lowers tool breakage and reduces the number of defective parts. The machine also schedules maintenance before something goes wrong, keeping production on track.

CNC intelligence isn't just about automation—it's about making every decision smarter.

Why integrate AI into CNC systems?

Even skilled machinists can’t detect every small error or performance change during production.

Integrating AI into CNC systems improves decision-making, automates problem-solving, and increases production efficiency through machine learning.

Artificial intelligence learns from machine data. Over time, it recognizes patterns—like how a tool wears down, or when a certain setting causes defects. It then suggests better settings or takes action automatically.

Benefits of AI in CNC

- Learns and improves over time

- Identifies issues before operators notice

- Makes precision adjustments faster than humans

- Reduces human involvement in repetitive tasks

Learning from Big Data

Modern CNC machines collect huge amounts of data—every vibration, speed change, or temperature shift. AI turns this data into smart suggestions, helping machinists make better decisions or even letting the system decide on its own.

AI-Driven Improvements

| Area Improved | AI Role |

|---|---|

| Surface Finish | Suggests better feed/speed |

| Tool Lifespan | Predicts replacement timing |

| Cycle Time | Identifies process bottlenecks |

| Energy Usage | Finds ways to cut unnecessary load |

Adding AI isn’t just a trend. It's becoming the new standard for competitive manufacturing.

Which industries use intelligent CNC?

Some industries need to make thousands of identical parts. Others make one complex piece with tight tolerances.

Industries like aerospace, medical, automotive, and electronics use intelligent CNC to meet high demands for accuracy, speed, and customization.

Whether the goal is precision, productivity, or both—CNC intelligence helps different industries stay competitive and improve product quality.

Industry Applications

| Industry | Application |

|---|---|

| Aerospace | Engine parts, structural frames |

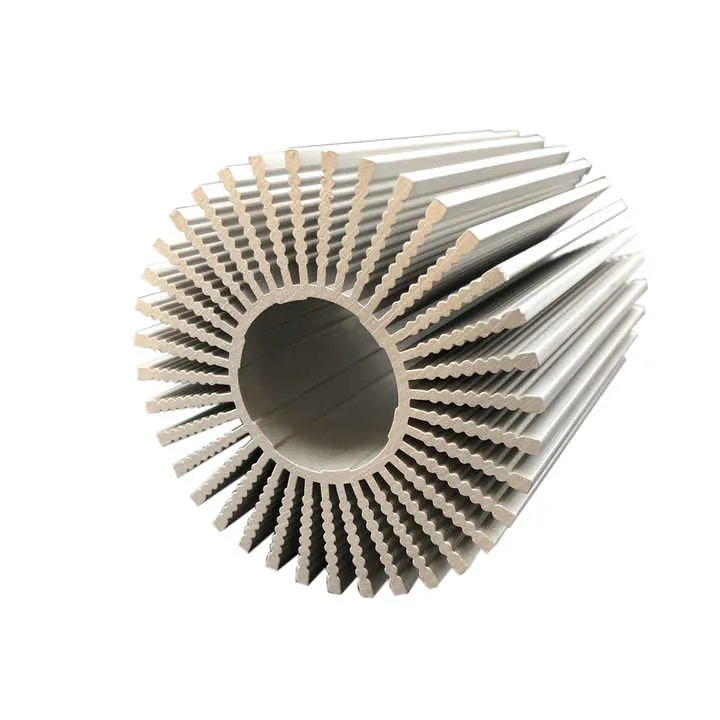

| Automotive | Transmission parts, aluminum housings |

| Medical | Surgical tools, custom implants |

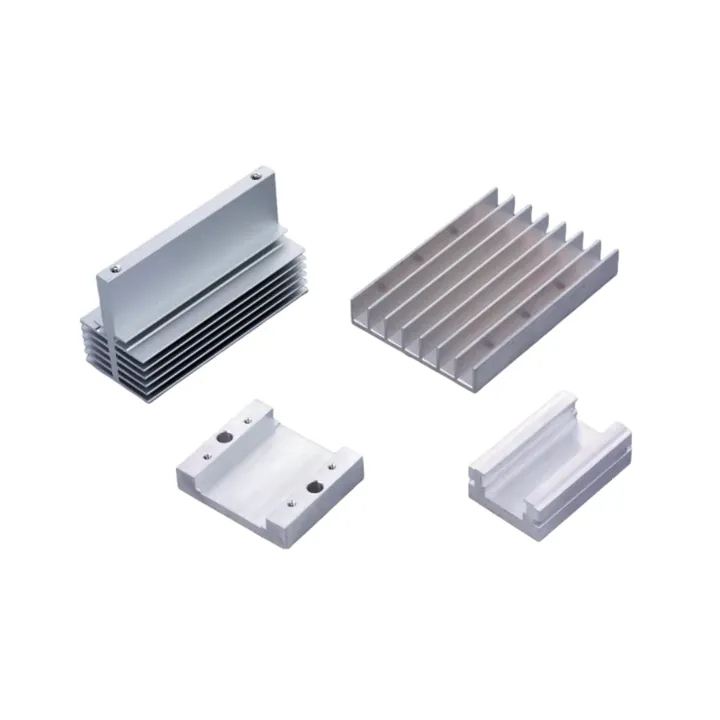

| Electronics | Heat sinks, aluminum enclosures |

| Tooling | Mold bases, dies, and precision tools |

Aluminum Machining in Automotive

In car manufacturing, aluminum parts like brackets and frames need tight tolerances. Intelligent CNC ensures these are machined consistently by adjusting parameters in real-time.

Custom Medical Parts

Hospitals and device makers often need complex, one-off parts. AI in CNC helps make these accurately without trial and error. This saves both time and materials.

By combining precision with automation, intelligent CNC helps each industry reach its quality and speed targets more easily.

Where is CNC intelligence applied?

Smart machining is not limited to high-tech labs. It’s already used in everyday factories worldwide.

CNC intelligence is applied in part design, production monitoring, tool control, and maintenance scheduling to enhance overall factory performance.

This technology is not just about the machine itself. It connects with design systems, quality control, and even logistics to build a smarter workflow.

Common Areas of Application

| Area | Role of CNC Intelligence |

|---|---|

| Design stage | Suggests better tool paths |

| Machining process | Adjusts feed, speed, coolant in real time |

| Quality inspection | Uses sensors to check part tolerance |

| Maintenance planning | Predicts tool or machine service needs |

Full Process Integration

At Sinoextrud, we use intelligent CNC to cut custom aluminum profiles. Our machines detect when a tool starts wearing out, and alert us before it breaks. This helps us avoid delays and deliver on time.

We also apply this system to optimize material usage. For example, by analyzing cutting patterns, the system suggests how to place parts more efficiently on each extrusion.

Logistics and Reporting

Data from intelligent CNC machines feeds directly into our production reports. This lets us track machine performance, delivery status, and even energy use, all in one place.

From first cut to final inspection, CNC intelligence improves every step of the journey.

Conclusion

CNC intelligence brings automation, precision, and adaptability together. With AI and real-time feedback, machining becomes faster, more accurate, and more reliable—making it essential for modern manufacturing.