When you need round parts made fast and accurately, the CNC lathe is the machine for the job. But what exactly does it do, and why is it so common in modern machining?

A CNC lathe is a computer-controlled turning machine that rotates material while a cutting tool removes material, making round or cylindrical parts with precision and speed.

This article explains how CNC lathes work, why they’re used across industries, what parts they make best, and where you’ll commonly find them in action.

How does a CNC lathe cut parts?

Unlike milling machines that spin the cutting tool, CNC lathes spin the material. The tool stays still while the part rotates — and that makes it perfect for anything round.

A CNC lathe cuts parts by rotating the workpiece at high speed while a stationary cutting tool moves across it, removing layers of material to create a desired shape.

The CNC (Computer Numerical Control) system tells the machine exactly how to move. The spindle holds and spins the material, while the turret (or tool post) moves the tool along two main axes — X (diameter) and Z (length).

Key CNC Lathe Functions

- Facing – cutting the front face flat

- Turning – reducing diameter along the length

- Boring – enlarging a hole inside the part

- Threading – cutting screw threads

- Parting – cutting off finished parts

- Grooving – cutting slots into the outer or inner surface

More advanced CNC lathes can also drill, tap, or mill using live tooling (driven tools). These are called CNC turning centers and offer multi-operation machining in one setup.

CNC Lathe Axis Table

| Axis | Function |

|---|---|

| X | Controls tool's movement in diameter direction |

| Z | Controls tool's movement along length |

| Y | Available in some models with milling function |

| C | Rotational control for spindle positioning |

CNC lathes can produce smooth finishes, tight tolerances, and consistent results with much less manual input than older manual lathes.

Why choose CNC turning?

For round parts, CNC turning is usually faster and more cost-effective than other methods. That’s why so many shops use lathes for high-volume parts and rotational components.

CNC turning offers speed, consistency, and accuracy for cylindrical parts. It reduces manual work, increases production rates, and produces uniform results with minimal waste.

Benefits of CNC Turning

- High Efficiency: Lathes are built for fast metal removal along cylindrical shapes.

- Tight Tolerances: Achieve ±0.01 mm or better on critical dimensions.

- Perfect for Volume: Once programmed, a lathe can make hundreds or thousands of identical parts.

- Low Waste: CNC precision means less scrap and better material use.

- Integrated Functions: Advanced models combine turning, drilling, and milling in one setup.

CNC Turning vs CNC Milling

| Feature | CNC Turning | CNC Milling |

|---|---|---|

| Rotation | Part rotates | Tool rotates |

| Best For | Cylindrical parts | Flat, complex shapes |

| Speed | Often faster for round parts | Slower for full profiles |

| Setup | Simpler for repetitive turning | More complex for 3D cuts |

If your part has a circular profile — like a pipe, rod, flange, or bushing — turning will usually be quicker and more cost-efficient.

Which parts suit lathe machining?

Not every part is right for a lathe. But if it spins or rolls, chances are it was made on one.

CNC lathes are best for making cylindrical, conical, or threaded parts like shafts, rings, bushings, fasteners, and fittings with symmetrical round features.

Ideal Lathe-Machined Parts

| Part Type | Description |

|---|---|

| Shafts | Used in motors, gearboxes, machines |

| Bushings | Support rotating parts, reduce friction |

| Housings | Circular cases for bearings or assemblies |

| Pipe Fittings | Round connectors for plumbing and piping |

| Fasteners | Bolts, screws, and threaded components |

| Spindles | Central axles for rotation in machines |

| Couplings | Mechanical joints for rotating systems |

Turning also works well for parts with multiple diameters, stepped profiles, and internal bores. In mass production, CNC turning is unbeatable in consistency and cost.

In the aluminum extrusion industry, for example, round connectors, support rods, or custom-length tubes are often trimmed and shaped using CNC lathes.

Where are CNC lathes applied?

CNC lathes are used in nearly every manufacturing sector — from aerospace to agriculture. Their flexibility makes them key machines in both mass production and custom part shops.

CNC lathes are widely used in automotive, aerospace, medical, oil & gas, consumer products, and industrial equipment manufacturing to produce high-precision round components.

Common Application Areas

| Industry | Example Parts |

|---|---|

| Automotive | Engine shafts, brake drums, pistons |

| Aerospace | Landing gear pins, hydraulic parts |

| Medical | Surgical tools, bone screws, implants |

| Oil & Gas | Threaded pipes, connectors, seals |

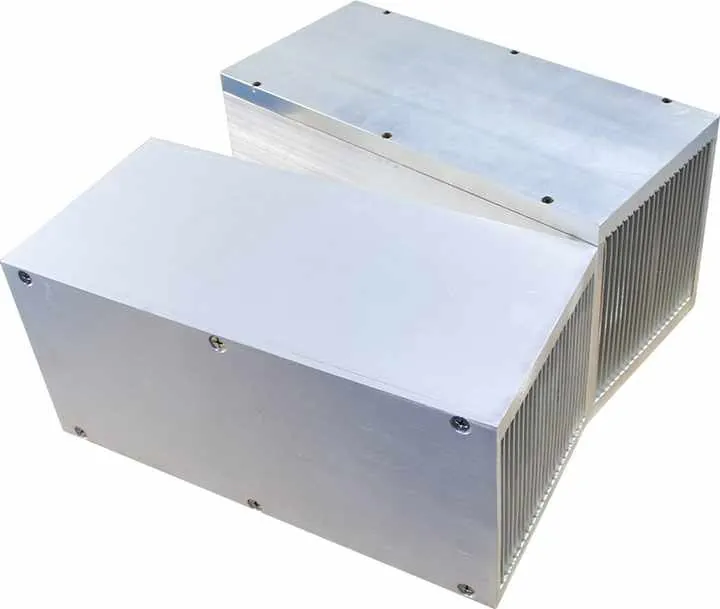

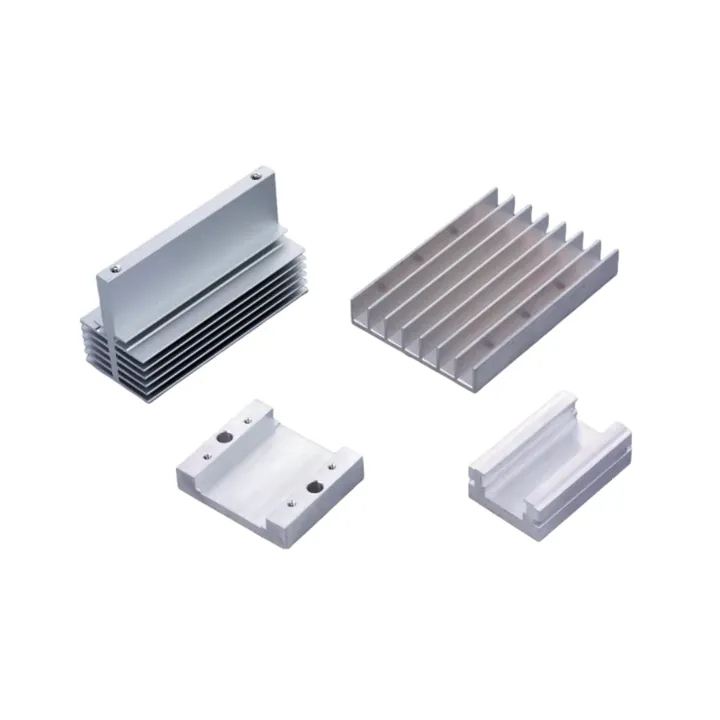

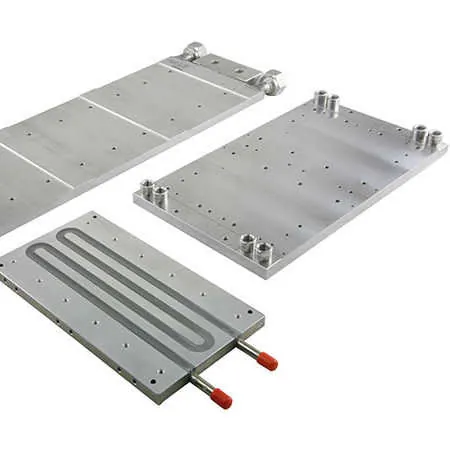

| Electronics | Metal enclosures, spacers, sleeves |

| Industrial | Rollers, gear blanks, rotating spindles |

| Plumbing | Pipe connectors, faucet components |

Smaller CNC lathes are also used by:

- Prototyping labs – quick test part creation

- Custom job shops – low-volume custom orders

- Universities & training centers – student learning

- DIY makerspaces – functional hobby parts

Many workshops pair CNC lathes with CNC mills or routers for complete part fabrication — turning for round parts, milling for flat surfaces and slots.

Conclusion

CNC lathes play a crucial role in modern machining. By spinning the material while the tool cuts, they create perfect round parts quickly and consistently. From simple bushings to complex multi-step components, lathes are the go-to machines for rotational precision. Whether in a mass production line or a custom workshop, CNC turning is essential to efficient and accurate manufacturing.