CNC machines have changed how parts and tools are made with speed and accuracy. Many shops switched to CAD‑CNC workflows to solve old problems and speed up production.

A CNC machine is a computer‑controlled tool that cuts, shapes, or drills material automatically. It follows exact digital instructions to make precise parts.

CNC machines can seem complex at first. This article explains how they work, why many factories use them, what jobs they handle best, and where they are used. Let’s dive in.

How does a CNC machine work?

CNC machines make parts by following digital designs. They move tools step by step based on computer commands.

A CNC machine uses a digital design file, converts it to tool paths, then moves cutting tools with motors and guides to shape material precisely.

To understand CNC operation, it helps to break it into steps:

1. Digital design and programming

First, a designer or engineer creates a computer model of the part. They use CAD (computer‑aided design) software. Then they export the design to a file, often in a standard format. Next, CAM (computer‑aided manufacturing) software converts the design into G‑code (or similar instructions). G‑code tells the machine exactly where to move, how fast, how deep to cut, and which tool to use.

2. Machine setup

The operator secures the workpiece in the machine. They pick proper tools (drill bits, endmills, cutters) and mount them. They also set the machine origin point — usually a “zero” point on the material. This origin ensures every cut follows the design coordinates correctly.

3. Motion control and cutting

Once started, the CNC controller reads the G‑code line by line. Stepper or servo motors move the cutting head along axes — commonly X, Y, and Z. Some machines also move on more axes (A, B, C) for rotation or complex motion. The machine moves the tool while spindle rotates at correct speed. Then the tool cuts, mills, drills, or engraves the material.

Over many small moves, the machine gradually removes material, shaping the part exactly. The work can be raw metal, plastic, wood, or composite.

4. Monitoring and finishing

Operator monitors the machine for safety and quality. After machining ends, they remove the part. Then they may deburr edges, smooth surfaces, or clean the part.

Key elements in CNC work

| Element | Role |

|---|---|

| CAD design | Defines the shape and geometry of the part |

| CAM software / G‑code | Translates design to machine instructions |

| Workpiece mounting & origin | Holds material and aligns start point |

| Motors and axes control | Move the tool precisely in 3D (or more) space |

| Tool selection | Determines how material is cut (drill, mill, engrave) |

| Spindle speed and feed rate | Control cutting quality and material removal speed |

Each part comes out nearly identical to the digital model. Reproduction is accurate and repeatable. That is why CNC machines replaced many manual tools.

Why are CNC machines used in manufacturing?

Manufacturers choose CNC machines for speed, precision, and repeatability. These machines reduce errors, save labor, and produce quality parts fast.

CNC machines bring consistent precision, fast production, and low labor cost — ideal for mass production and tight tolerances.

Using a CNC brings many advantages over manual machining. These help in modern manufacturing:

Consistent quality and precision

Manual methods rely heavily on worker skill. Even a skilled machinist can make small mistakes. CNC removes much of this variability. Because the machine follows the same digital instructions each time, parts are identical, within tight tolerance. This is critical in sectors like aerospace or medical devices where even tiny variation can cause problems.

Higher production speed and efficiency

Once the machine is programmed and setup, it can run with minimal supervision. It works faster than manual cutting or drilling. It reduces idle time, and can often run overnight or unattended. This boosts throughput. Also setup changes (for a new part) just need a new digital file — no need to craft jigs or manual templates.

Lower labor cost and skill barrier

Manual machining requires highly skilled labor. Skilled machinists are expensive and in short supply. With CNC, less manual skill is needed for production. Once setup is done, an operator with basic training can run the machine. This reduces labor cost and lowers risk of human error.

Flexibility and ease of design changes

When design changes occur, engineers just update the digital file. Then they load it on the CNC and run. No need to redesign cutting tools or templates. This flexibility suits custom parts, prototypes, or small batch jobs.

In many manufacturing settings, these advantages make CNC the default choice over manual milling, drilling, or turning.

Which tasks are best suited for CNC machines?

Some tasks match CNC strengths better than others. CNC excels when precision, repeatability, and complexity matter. Simple rough work might not need it.

CNC machines perform best on tasks requiring precise geometry, repeat cuts, complex shapes, or high volume production.

To decide whether CNC is right for a job, consider these factors:

Ideal tasks for CNC

| Task type | Why CNC fits |

|---|---|

| Complex shapes and contours | CNC can move in multiple axes with small increments — good for curved or irregular surfaces |

| High precision parts | CNC tolerances are tight and repeatable — useful when parts must match exactly |

| High volume production | Once programmed, CNC can run many pieces with little oversight, lowering per-part cost |

| Prototypes and custom parts | Digital changes are easy — good for one-off or small batch production |

| Hard materials (metal, composite) | CNC tools and machines can handle metals that are difficult to shape manually |

| Parts requiring drilling, milling, turning in one setup | Some CNC machines (like 5-axis) combine operations to save time |

Less suited tasks

- Very rough or simple cuts — manual tools might be cheaper.

- Small one-off parts where setup time and programming outweigh the benefit.

- Soft materials where manual tools suffice and can be quicker.

Examples of great CNC tasks

- Machining an aluminum part with complex curves and holes.

- Producing dozens or hundreds of identical metal brackets.

- Cutting precise plastic components for electronics.

- Milling molds or dies for manufacturing.

- Creating prototype parts when design may change soon.

CNC shines when precision, repeatability, and flexibility matter. For rough, simple tasks — manual methods might still win in cost or speed.

Where are CNC machines applied?

CNC machines appear in many industries and workshops. They help make parts for planes, cars, machines, electronics, and more.

CNC machines are used in aerospace, automotive, electronics, mold‑making, and custom fabrication shops worldwide.

Here are some common places where CNC appears:

Aerospace and aviation

Aircraft parts need extremely tight tolerances and strong materials. CNC mills make wing parts, structural frames, engine components from metals like aluminum, titanium, or steel. CNC ensures each part matches design exactly. This helps safety and performance in aircraft.

Automotive and transportation

Car parts, engine blocks, transmission parts, brackets, chassis components — many come from CNC machines. For custom car parts or small production runs, CNC gives flexibility. For high‑volume runs, CNC ensures consistency across thousands of parts.

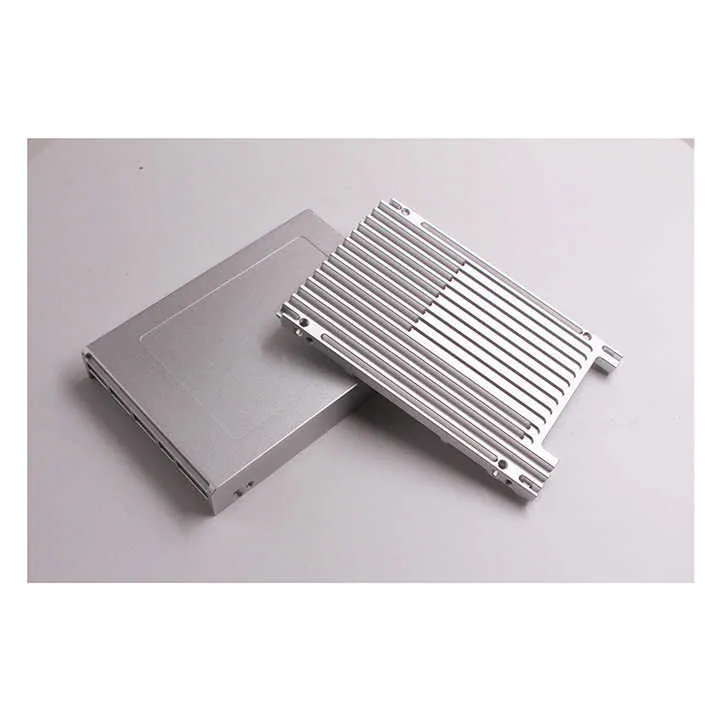

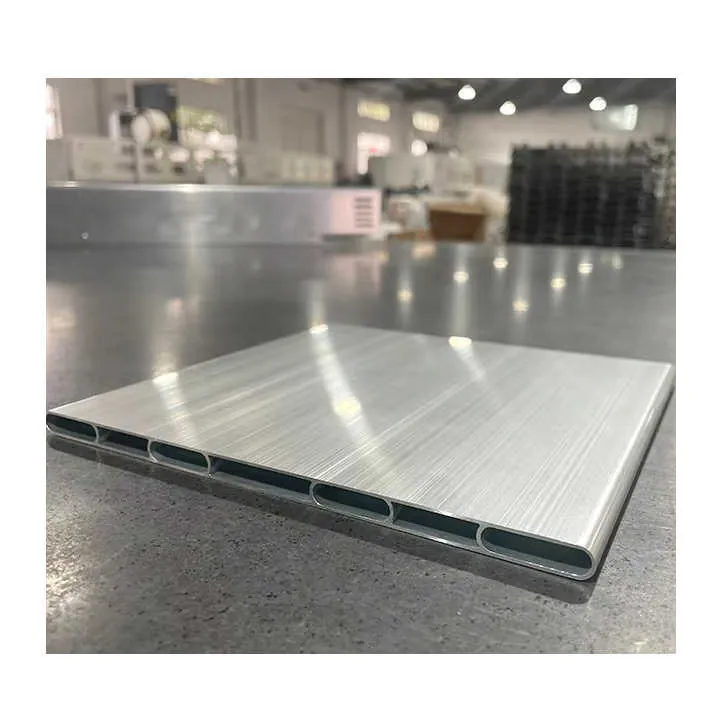

Electronics and semiconductor equipment

Electronics need precise housings, connectors, or heatsinks. CNC can cut plastics, aluminum, or composite materials with high accuracy. For labs or small batches, CNC helps produce custom enclosures or prototypes.

Mold, die, tool making

Molds for injection molding, dies for stamping, or tooling parts often need complex geometry and precision. CNC machines cut molds from hardened steel or aluminum. This application is critical for producing many identical parts through casting or molding.

Custom fabrication and prototypes

Small shops, designers, or inventors use CNC to make one‑off or small batch parts. This includes musical instruments, art pieces, furniture hardware, machine parts, or mechanical prototypes.

Medical devices and equipment

Medical tools, implants, or medical device housings often require high precision and biocompatible materials. CNC enables production of custom metal parts, small and complex shapes, and small batch runs.

Industry usage overview

| Industry | Common CNC outputs |

|---|---|

| Aerospace | Structural components, engine parts |

| Automotive | Engine blocks, frames, custom parts |

| Electronics | Enclosures, heatsinks, precision mounts |

| Tool & die | Injection molds, tools, dies |

| Medical | Implants, surgical tools, device housings |

| Custom fabrication | Prototypes, art, hardware |

Because of its flexibility and precision, CNC has become standard in many sectors.

Conclusion

CNC machines combine computer control with mechanical tools to make precise, repeatable parts. They suit jobs needing accuracy, complexity, and consistent quality. Many industries rely on CNC from aircraft to medical to electronics. For precise and efficient manufacturing, CNC is often the best choice.