CNC machine tools are transforming modern manufacturing, but many still struggle to understand what they truly are.

A CNC machine tool is a computer-controlled system that automates cutting, drilling, milling, and shaping materials with high accuracy and speed.

Unlike manual machining, CNC eliminates human error and boosts consistency. Let’s go deeper to understand how it works, why it’s accurate, what tools are common, and where it’s used.

How do CNC machine tools operate?

Most people know CNC tools work automatically, but few understand what happens behind the scenes.

CNC machine tools operate using pre-programmed software that directs the movement of the cutting tools and workpiece in precise patterns.

CNC stands for “Computer Numerical Control.” In practice, a computer reads instructions from a digital file, typically in G-code format. This file tells the machine what movements to perform, how fast to move, and where to cut. Once the code is uploaded, the machine follows the instructions exactly.

Three Key Components of Operation

- Control Software: Translates CAD files into movement instructions.

- Drive Motors and Actuators: Move the tools in X, Y, and Z directions.

- Feedback System: Sensors monitor accuracy in real-time and make adjustments.

Workflow Breakdown

| Step | Description |

|---|---|

| Design | CAD (Computer-Aided Design) creates a 3D model of the part |

| Programming | CAM (Computer-Aided Manufacturing) converts it to machine code |

| Setup | Operator secures the workpiece and loads the program |

| Execution | Machine follows the code to cut, drill, or shape the material |

| Feedback | Sensors check tool positioning and correct minor errors automatically |

By removing the manual process, CNC machining reduces errors, shortens production time, and allows for 24/7 operations. It also enables repeatability—one program can produce thousands of identical parts.

Why are CNC tools more accurate?

Even skilled machinists make mistakes, but CNC tools rarely do. Why is that?

CNC tools are more accurate because they follow exact computer-generated paths, eliminating human errors and ensuring consistent tolerance levels.

The precision of CNC tools comes from their ability to repeat the same action without deviation. They don’t rely on human strength or judgment. Instead, they rely on software instructions and real-time feedback from sensors.

Precision Through Automation

In manual machining, a human adjusts levers or wheels to control the cutting tool. This creates room for fatigue and inconsistency. In contrast, CNC systems use servo motors and closed-loop feedback to maintain exact dimensions.

Example of Accuracy Levels

| Machine Type | Tolerance Range |

|---|---|

| Manual Lathe | ±0.05 mm |

| CNC Milling Machine | ±0.005 mm |

| High-Precision CNC | ±0.002 mm |

Factors Enhancing Accuracy

- Zero backlash drive systems reduce play between moving parts.

- Thermal compensation corrects for heat expansion during cutting.

- Automatic calibration maintains cutting tool sharpness and positioning.

This level of control allows CNC to meet the strict demands of aerospace, medical, and electronics industries, where even small deviations can lead to failure.

Which CNC tools are most common?

There are many types of CNC tools, and not all are used the same way.

The most common CNC machine tools include milling machines, lathes, routers, laser cutters, and plasma cutters.

Each of these tools performs a different function, and they are selected based on the material, shape, and type of operation needed.

Types of CNC Tools

1. CNC Milling Machines

- Use rotating tools to remove material.

- Ideal for cutting slots, holes, and contours.

2. CNC Lathes

- Rotate the workpiece while cutting tool remains stationary.

- Excellent for creating round objects like shafts and bolts.

3. CNC Routers

- Similar to milling machines but typically work on softer materials like wood and plastic.

- Used in signage, furniture, and composite panels.

4. CNC Laser Cutters

- Use a laser beam to melt or vaporize material.

- Very precise, often used in sheet metal fabrication.

5. CNC Plasma Cutters

- Cut through conductive materials using a plasma torch.

- Mostly used for cutting steel, aluminum, and brass.

Comparison Table

| CNC Tool | Best For | Material Types |

|---|---|---|

| Milling Machine | 3D contours, detailed parts | Metals, Plastics |

| Lathe | Cylindrical shapes | Metals, Composites |

| Router | Flat panels, artistic cuts | Wood, Foam, Plastics |

| Laser Cutter | Fine cuts, engraving | Metals, Acrylics |

| Plasma Cutter | Thick metal sheets | Steel, Aluminum |

Each of these tools can be automated through CNC technology, leading to higher throughput and better precision than manual tools.

Where are CNC machine tools applied?

Some still believe CNC is only for factories. The reality is much broader.

CNC machine tools are widely used in automotive, aerospace, construction, electronics, and even furniture production.

Key Industries Using CNC Tools

Automotive

Car makers use CNC machines to produce engine parts, gearboxes, and chassis components. Consistency and speed are critical in this sector.

Aerospace

Aircraft components must meet tight tolerances. CNC tools deliver precise, certified parts for turbines, wings, and cabin fixtures.

Construction and Architecture

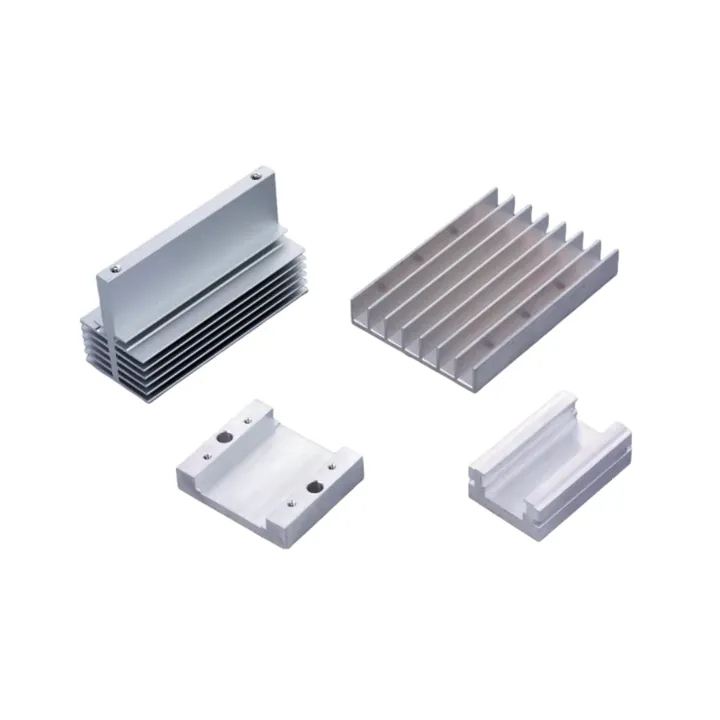

CNC milling and cutting are used to create aluminum frames, brackets, and façade systems for buildings.

Electronics

CNC machines help produce circuit boards and custom metal housings for devices. The accuracy prevents overheating and ensures device safety.

Furniture

CNC routers cut wood panels for desks, cabinets, and decorative panels. This supports mass production while keeping designs consistent.

Specialized Applications

- Medical devices: Implants, surgical tools, and dental components.

- Defense: Drone parts, weapon mounts, and armored components.

- Energy: Turbine blades, solar panel frames, and heat exchangers.

By adapting to different materials and operations, CNC tools play a role across nearly every modern manufacturing field. Whether for small parts or large structures, CNC is now a vital part of global production.

Conclusion

CNC machine tools have reshaped how industries manufacture products. By automating precision work, they reduce errors, improve speed, and support complex designs that manual tools cannot achieve. Their role continues to grow across industries that demand quality and consistency.