CNC machinery is a game-changer in modern manufacturing, offering unmatched precision and efficiency. It’s revolutionizing how industries produce components, providing greater control and higher accuracy.

CNC machinery refers to Computer Numerical Control equipment that automates machine tools using computer programming. It’s vital in modern manufacturing, offering high precision, versatility, and efficiency.

Before we dive into the details of CNC machinery, let’s take a closer look at the core machines involved and how they’re transforming industries worldwide.

What Types of Machines Fall Under CNC Machinery?

CNC machinery includes a wide range of machines, each designed for specific tasks in the manufacturing process. Here’s a breakdown of the most common types:

-

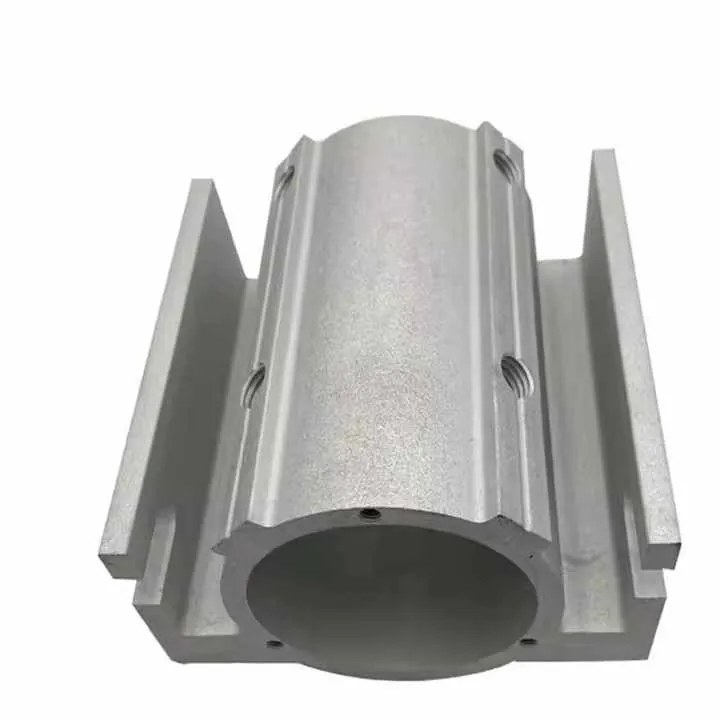

CNC Lathes: These machines are used for turning operations, where the material is rotated while a stationary cutting tool shapes it. CNC lathes are excellent for creating cylindrical parts, like shafts or bolts, with high precision.

-

CNC Mills: CNC milling machines use rotating cutting tools to remove material from a workpiece. They are versatile and can be used for drilling, boring, and cutting complex shapes in materials like metal, plastic, or wood.

-

CNC Routers: These are similar to milling machines but are typically used for larger workpieces or softer materials. CNC routers are commonly used for woodworking and plastic machining.

-

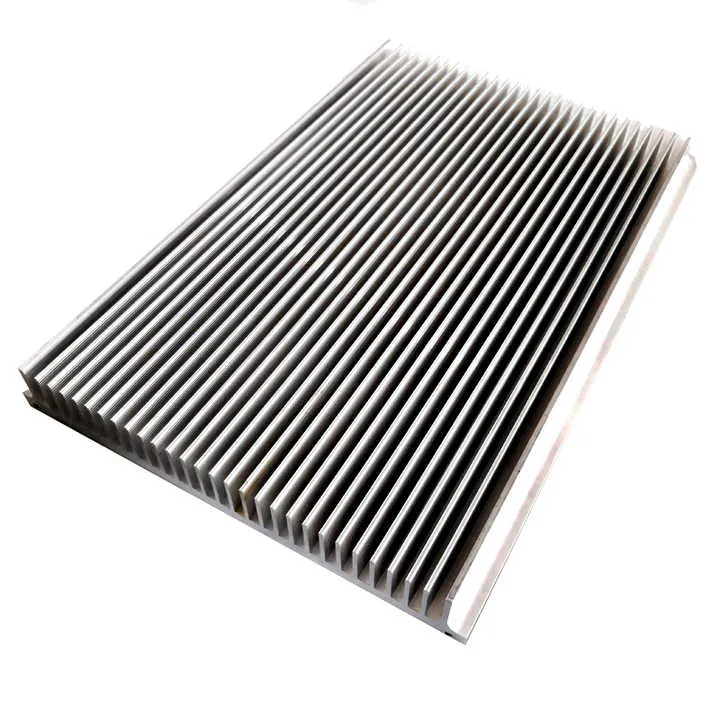

CNC Grinders: These machines use abrasives to remove material from a workpiece, making them ideal for producing smooth, precise surfaces. CNC grinders are crucial for industries that need to achieve high tolerances, such as aerospace or automotive.

-

CNC Laser Cutters: Laser cutters are often used for cutting or engraving materials like metal, wood, and plastic. They offer extreme precision and are commonly found in industries like sign-making or sheet metal fabrication.

-

CNC Plasma Cutters: Plasma cutting machines use high-temperature ionized gases to cut through conductive materials. They’re ideal for industries that require fast cutting of thicker materials, such as steel.

Each of these machines is controlled by a computer, using software that translates the design into precise movements. This automation significantly improves consistency and reduces human error in production.

Types of CNC Machines Overview

| Machine Type | Common Applications | Key Features |

|---|---|---|

| CNC Lathes | Turning cylindrical parts, shafts | High precision in round workpieces |

| CNC Mills | Drilling, boring, and cutting | Versatile in creating complex shapes |

| CNC Routers | Woodworking, plastic machining | Larger workpieces and softer materials |

| CNC Grinders | Achieving smooth, precise surfaces | High tolerance, ideal for finishing |

| CNC Laser Cutters | Cutting, engraving, and marking | Extremely precise, works on various materials |

| CNC Plasma Cutters | Fast cutting of metals | High-speed cutting, especially for thick materials |

Why is CNC Machinery Important for Modern Manufacturing?

CNC machinery has become indispensable in modern manufacturing because it enables manufacturers to achieve levels of precision, speed, and consistency that were previously unattainable.

CNC machinery is crucial for modern manufacturing because it enables high-precision work, reduces human error, and increases the speed and efficiency of production.

Let’s explore how CNC technology has reshaped the manufacturing landscape by offering solutions that optimize processes across industries.

CNC machinery plays a pivotal role in modern manufacturing by providing numerous advantages that set it apart from traditional machining methods:

-

Precision: One of the main reasons CNC machinery is so important is its ability to achieve a level of precision that would be difficult, if not impossible, with manual labor. CNC machines can follow complex designs and produce parts with incredibly tight tolerances. This precision is critical for industries like aerospace, automotive, and electronics, where even the slightest error can lead to significant issues.

-

Efficiency and Speed: CNC machines can operate 24/7 without the need for breaks, reducing the overall production time and increasing output. This level of automation allows manufacturers to produce large quantities of products with minimal human intervention, making production lines faster and more efficient.

-

Consistency: CNC machines can replicate the same part over and over with identical precision, ensuring uniformity across all products. This is particularly valuable for industries that require high volumes of identical parts, such as the medical or consumer electronics sectors.

-

Complexity: CNC machines are capable of performing intricate operations like drilling holes, cutting curves, and creating multi-dimensional shapes. These advanced capabilities allow manufacturers to produce highly complex components that would be difficult to achieve with manual machines.

-

Reduced Labor Costs: While CNC machinery requires skilled operators, it reduces the need for large numbers of manual workers on the shop floor. This can lead to cost savings in labor while maintaining high levels of production.

In essence, CNC machinery helps modern manufacturers remain competitive by providing high precision, lower labor costs, faster production times, and the ability to create complex and consistent parts.

Benefits of CNC Machinery for Modern Manufacturing

| Benefit | Description |

|---|---|

| High Precision | Produces parts with extremely tight tolerances |

| Increased Efficiency | Operates 24/7, reducing production time and costs |

| Consistency | Ensures uniformity across large batches of products |

| Complex Shapes | Capable of creating intricate designs and features |

| Reduced Labor Costs | Decreases the need for manual workers on the floor |

How Does CNC Machinery Enhance Production Efficiency?

CNC machinery drastically improves production efficiency by automating complex tasks, minimizing waste, and boosting production speeds.

CNC machinery enhances production efficiency by automating complex processes, reducing waste, and improving the speed at which products are made. This leads to faster production and more cost-effective operations.

Understanding how CNC machinery enhances production efficiency can help industries improve their processes, save costs, and boost profitability.

CNC machinery is a game-changer when it comes to enhancing production efficiency. By automating several key processes, CNC systems allow manufacturers to produce parts much faster than traditional methods. Here’s how CNC machinery drives efficiency:

-

Automation of Complex Tasks: CNC machines can automate processes that would otherwise require highly skilled labor. This includes tasks like drilling, cutting, and milling, which can now be completed with minimal human intervention. Automation also reduces the likelihood of human error, improving both efficiency and consistency.

-

Faster Production Cycles: With CNC machinery, once a design is programmed into the system, the machine can run continuously, producing parts at a much faster rate than manual labor. This is especially useful in industries where large quantities of parts need to be produced in a short time frame, like automotive or consumer electronics.

-

Reduced Material Waste: CNC machines are precise and accurate, meaning they can minimize the amount of material wasted during the manufacturing process. This is crucial for industries where raw materials are expensive, like aerospace or high-end electronics. By reducing waste, CNC machines help manufacturers save money on materials and improve their environmental footprint.

-

Fewer Setup Times: Traditional manufacturing often requires lengthy setup times for each new batch or part. With CNC machinery, the setup process is much quicker, as the program simply needs to be adjusted to suit the new design. This reduces downtime between production runs, further improving overall efficiency.

-

Improved Quality Control: CNC systems can be programmed to constantly monitor production and ensure that every part meets the required specifications. This constant oversight helps eliminate defects and ensures that products are made to the highest standards, reducing the need for rework and inspection.

Efficiency Gains with CNC Machinery

| Efficiency Factor | How CNC Improves It |

|---|---|

| Automation | Automates complex processes, reducing manual labor |

| Speed | Speeds up production cycles and increases output |

| Material Usage | Minimizes waste, saving on materials |

| Setup Times | Reduces downtime between production batches |

| Quality Control | Constant monitoring ensures high product quality |

Where is CNC Machinery Most Commonly Used?

CNC machinery is used in a wide range of industries, from aerospace to consumer goods, thanks to its versatility and ability to handle complex tasks.

CNC machinery is used in many industries, including aerospace, automotive, electronics, medical devices, and consumer goods, thanks to its precision, speed, and versatility.

Understanding where CNC machinery is applied can help industries optimize their use and realize the full benefits of this technology.

CNC machinery is found across numerous industries, each benefiting from its precision, speed, and ability to handle complex tasks. Some of the most common industries where CNC machines are used include:

-

Aerospace: The aerospace industry relies heavily on CNC machinery for producing high-precision components, such as turbine blades, structural parts, and brackets. The strict tolerances required in aerospace make CNC machines an indispensable tool for manufacturers in this field.

-

Automotive: CNC machines are used extensively in the automotive industry to produce parts like engine components, suspension parts, and interior fittings. The speed and precision of CNC machinery help automotive manufacturers meet the high demand for parts while maintaining quality.

-

Electronics: In electronics, CNC machinery is used to create components like circuit boards, housings, and connectors. CNC machines can handle the tiny, intricate designs required in electronics, ensuring that parts fit together perfectly.

-

Medical Devices: The medical device industry benefits from CNC machines in the production of components such as implants, surgical tools, and diagnostic equipment. These parts must be highly precise, and CNC machinery ensures that they are made to exact specifications.

-

Consumer Goods: CNC machines are also widely used in the production of consumer goods, including appliances, furniture, and packaging. CNC routers, for instance, are used to cut and shape wood and plastic for furniture or decorative items.

-

Tooling and Machinery: CNC machines are used to manufacture other tools and machines, such as molds, dies, and jigs. This is a vital part of the tooling industry, as CNC machines ensure high precision and repeatability in the production of these essential components.

Key Industries Using CNC Machinery

| Industry | Common Applications |

|---|---|

| Aerospace | High-precision components like turbine blades and brackets |

| Automotive | Engine parts, suspension components, interior fittings |

| Electronics | Circuit boards, connectors, housings |

| Medical Devices | Implants, surgical tools, diagnostic equipment |

| Consumer Goods | Furniture, appliances, packaging |

| Tooling & Machinery | Molds, dies, and jigs |

Conclusion

CNC machinery has become an integral part of modern manufacturing, offering precise control, increased efficiency, and reduced production times. It’s essential for industries ranging from aerospace to automotive, helping to produce high-quality parts with minimal waste.