CNC machining has become the core of how modern products are built. Whether it's an airplane part or a smartphone frame, chances are it was shaped by a CNC machine.

CNC manufacturing uses computer-controlled machines to cut, drill, turn, and shape materials into finished products. This process improves accuracy, reduces waste, and speeds up production in nearly every industry.

Let's explore how CNC boosts manufacturing, why it's essential in modern factories, what products rely on it, and where it's used today.

How does CNC improve manufacturing?

Manufacturing today demands precision, repeatability, and speed. Manual tools can’t meet that demand at scale. CNC machines solve that problem.

CNC machining improves manufacturing by delivering precise, consistent, and automated production — reducing errors, increasing output, and allowing complex designs.

Here's what CNC brings to the factory floor:

- Automation: Machines follow programmed instructions without human input.

- Consistency: Every part matches the original CAD model, even in large batches.

- Speed: CNC machines work fast, often running 24/7 with minimal downtime.

- Complex Shapes: They handle multi-axis cuts, curved surfaces, deep holes, and intricate paths.

- Multi-Material Capability: CNC can process metals, plastics, composites, and more.

CNC vs Manual Production

| Factor | Manual Machining | CNC Machining |

|---|---|---|

| Accuracy | Operator-dependent | Program-controlled |

| Speed | Slower | Fast and continuous |

| Labor Cost | High | Lower per part |

| Part Variation | Inconsistent | Uniform |

| Complexity | Limited | High – 3D shapes, multi-axes |

In short, CNC transforms manufacturing from craftsmanship into repeatable, high-efficiency production.

Why integrate CNC in factories?

Adding CNC machines to a factory changes how it works. Instead of manual steps, machines take over — faster and more consistently.

Factories integrate CNC to boost output, improve quality, reduce errors, lower labor dependency, and stay competitive in a digital, high-speed manufacturing world.

Key Benefits of CNC Integration

- Scalability: Machines can run continuously, producing thousands of identical parts.

- Rapid Prototyping: From CAD model to prototype in hours, not days.

- Lower Waste: With precise cutting paths, CNC uses less raw material.

- Reduced Downtime: Smart diagnostics and automated tool changes minimize pauses.

- Better Planning: CNC data helps track performance and predict maintenance.

Factories today link CNC systems to software platforms — such as MES (Manufacturing Execution Systems) or ERP systems — to track orders, manage tooling, and monitor production in real-time.

Advanced CNC setups also support:

- Automated tool changers

- Robotic arms for loading/unloading

- Remote monitoring

- Integrated quality control systems

Whether it's a small workshop or a global plant, CNC brings digital control and predictability to physical production.

Which products rely on CNC?

CNC is behind more products than most people realize. Any part that needs precision, repetition, or complex geometry probably came from a CNC machine.

Products that rely on CNC machining include automotive parts, airplane components, medical devices, electronics, industrial machinery, tools, and custom aluminum profiles.

Examples by Industry

| Industry | CNC-Machined Products |

|---|---|

| Aerospace | Turbine blades, engine housings, brackets |

| Automotive | Engine blocks, gears, chassis components |

| Medical | Implants, surgical tools, orthopedic screws |

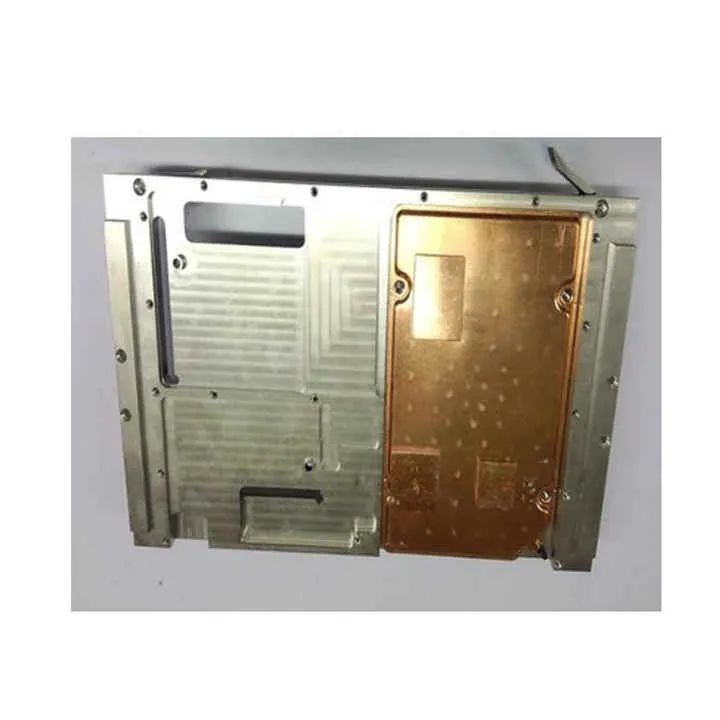

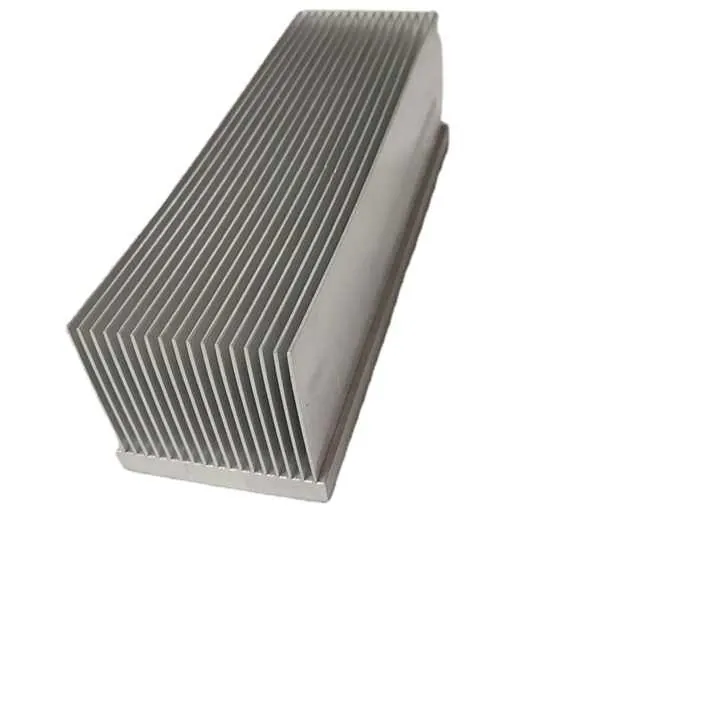

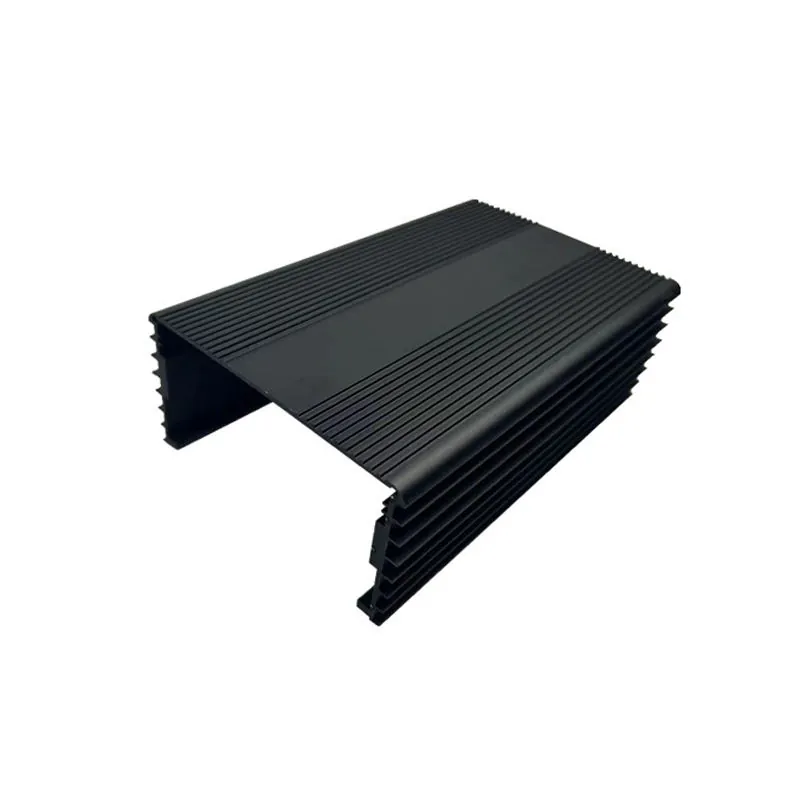

| Electronics | Heat sinks, enclosures, connectors |

| Construction | Window frames, curtain wall fittings |

| Robotics | Gears, linkages, frame joints |

| Consumer Goods | Watches, bike parts, kitchen tools |

Even items with smooth finishes, such as smartphone frames or laptops, often start with CNC-milled casings.

Part Types Commonly CNC-Machined

- Shafts and rods

- Bushings and spacers

- Housings and brackets

- Heat sinks and covers

- Valve bodies and connectors

For companies like ours that specialize in aluminum extrusion, CNC machining plays a vital role in trimming profiles, drilling holes, milling end faces, and adding features that extrusion alone can’t achieve.

Where is CNC manufacturing adopted?

CNC machines are used in nearly every country and industry — from local job shops to international aerospace plants. They power everything from prototypes to mass production.

CNC manufacturing is adopted in aerospace, automotive, medical, electronics, defense, furniture, heavy industry, and custom manufacturing worldwide.

Typical Locations Using CNC

- Aerospace Factories: For engine parts, fuselage components, and lightweight structural frames.

- Automotive Plants: For engine machining, wheel hubs, dashboards, and custom accessories.

- Medical Equipment Labs: For implants, dental devices, and surgical tools requiring micron-level precision.

- Electronics Assembly Centers: For casings, brackets, and heat sinks.

- Tool & Die Shops: For molds, jigs, fixtures, and metal stamping dies.

- Furniture Factories: For customized wood or metal elements.

- Prototype & R&D Labs: For testing and iterating part designs.

Many companies also use CNC for:

- Small batch manufacturing

- Low-volume custom production

- Repair and retrofitting

- Custom aluminum profile processing

CNC technology is not only for large corporations. It's widely accessible and used by small to mid-size companies to meet modern production standards without excessive labor costs.

Conclusion

CNC machining and manufacturing represent the shift from manual, variable production to automated, consistent, and scalable processes. With the ability to cut, drill, and shape materials using digital instructions, CNC helps factories across the world make better parts faster. Whether you're in aerospace, electronics, or construction, CNC brings the control, flexibility, and precision modern manufacturing needs to stay competitive.