A CNC machining center is an advanced, computer‑controlled machine tool that performs a range of machining tasks automatically. It cuts, mills, drills, and shapes materials with high precision under digital control.

A CNC machining center brings together milling, drilling and tool‑changing automation — enabling complex parts to be produced with minimal manual work.

Continue reading to learn how such a machine works, why shops use it, what tasks it excels at, and where it's applied.

How does a CNC machining center work?

Selecting the wrong tool often leads to wasted time or poor parts. CNC machining centers solve that by using computer code to drive precise tool movements.

A CNC machining center reads programmed code (like from CAD/CAM), then the machine moves its spindle and tools in 3 (or more) axes to cut or shape a workpiece automatically.

A machining center begins with a digital design of the part. That design is converted into machine instructions (such as G‑code). The machine’s control system interprets the code. It directs motors and actuators to move the worktable or the spindle along axes (commonly X, Y, Z). The workpiece is clamped securely while the spindle holds cutting or drilling tools.

When equipped with an automatic tool changer (ATC), the machining center can switch between different tools (e.g. drills, mills, taps) without manual intervention. That allows a single clamping to handle multiple operations — for example, drilling holes, milling contours, pocketing, tapping threads — all in one run.

Tool paths, feed rates, spindle speed and depth are all controlled precisely. This control enables tight tolerance and consistent surface finish. Because the motion is computer‑driven, repeatability between parts is very high.

Thus, a CNC machining center automates complex machining tasks. It replaces multiple manual machines or manual tool changes with a single, efficient system.

Why use machining centers for production?

Manual machining or basic CNC mills often require frequent tool changes or multiple setups. That slows production and increases cost. Machining centers avoid those issues.

Machining centers raise productivity, reduce manual labor, and ensure consistent quality — ideal for batch production or complex parts.

The automatic tool changer lets the machine run many operations in one setup. That saves time because operators don’t need to stop and swap tools. This increases throughput and reduces chance of human error.

Machining centers also offer flexibility. They can be quickly reprogrammed to produce different parts. This suits small-batch production or custom parts. They handle complex shapes, contours, holes, threads, and many features in one piece.

Because of high precision and repeatability, machining centers satisfy tight tolerances and surface‑finish requirements. That matters when parts must fit exactly, or when multiple identical parts are needed.

Finally, automation reduces labor need and human error. One operator can oversee several parts running, while machine does the heavy work. That reduces cost per piece and improves consistency.

For all these reasons, machining centers form the backbone of modern precision manufacturing.

Which tasks are best for CNC machining centers?

Some tasks are too simple for a full machining center, while others nearly require it. The best tasks for machining centers combine complexity, multiple operations, and need for consistency.

Machining centers excel at multi‑step machining: milling, drilling, tapping, contouring, shaping complex 3D geometry, and handling parts needing tight tolerance.

Typical tasks include:

- Milling complex shapes: pockets, slots, contours, 3D surfaces

- Drilling holes, tapping threads, boring — multiple hole operations in one setup

- Machining parts with multiple features on different faces, without reclamping

- Producing components with precise dimension and repeatable quality across batches

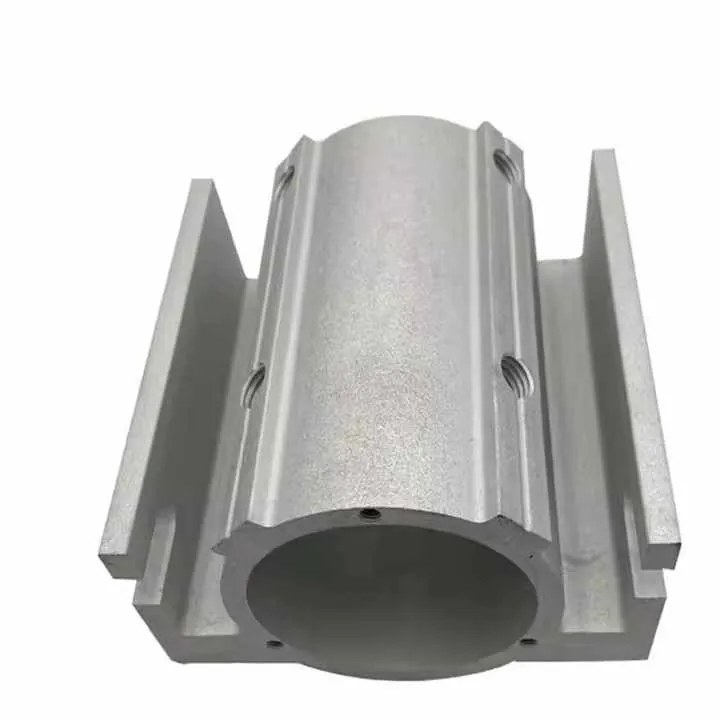

- Making parts from metals, plastics or composites — especially when shape is complicated or parts tall/3‑dimensional

If a part needs only a simple cut, or if it’s a large flat panel, simpler machines might suffice. But if part needs drilling, milling, threading, and complex geometry, machining centers pay off.

Also, when a shop handles variety — different parts every day — the flexibility and tool‑change capacity of machining centers makes them a practical all‑in‑one solution.

Where are CNC machining centers applied?

Machining centers appear across many industries. Anywhere precision, variety, or volume is needed, they offer value.

Industries that use CNC machining centers include automotive, aerospace, industrial machinery, mold & die making, metal fabrication, and custom components manufacturing.

| Industry | Common Applications | Why Machining Centers Fit |

|---|---|---|

| Automotive | Engine blocks, housings, precision mounts | High volume + precision + speed |

| Aerospace | Aluminum/titanium structures, brackets, fittings | 3D shapes, tight tolerances |

| Mold & Die Making | Injection molds, stamping dies, forging dies | Hard materials + complex surfaces |

| Industrial Equipment | Machine parts, gear cases, automation parts | Mixed jobs, multiple tool paths |

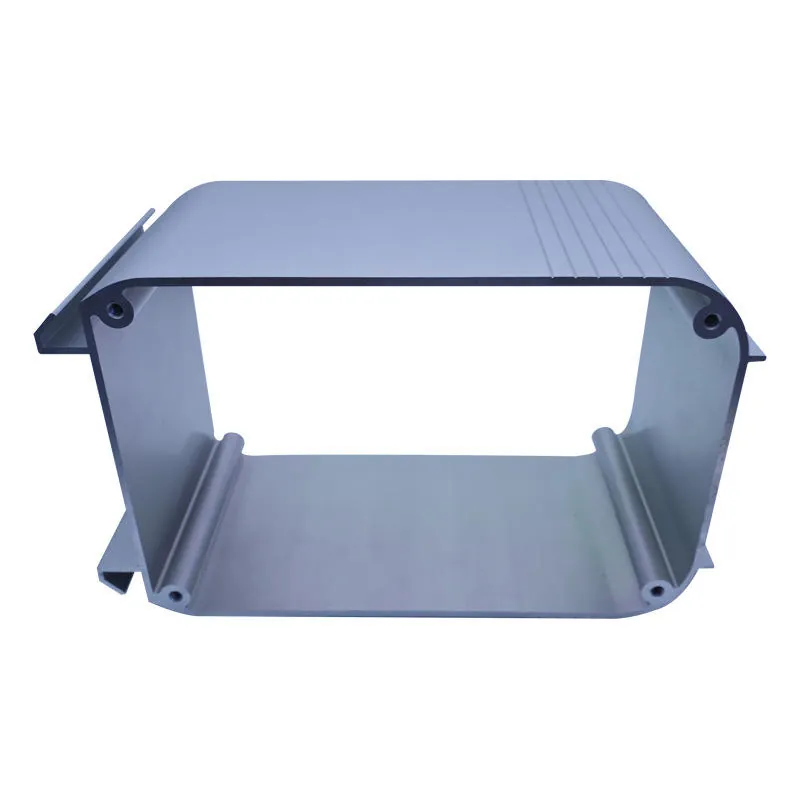

| Consumer Electronics | Small metal enclosures, connectors, casings | Fine detail, repeatability |

Machining centers help reduce cost per part and improve quality in these sectors. Whether producing hundreds of parts per day or small batches, they bring consistent performance.

The flexibility of CNC machining centers also allows contract manufacturers to serve different industries with short lead times. As demand shifts, the machine can switch jobs with a software change and tool reload.

In all these industries, CNC machining centers are not just tools — they are part of the production system. They integrate with CAD/CAM systems, MES tracking, and quality control. That’s why their use continues to grow.

Conclusion

A CNC machining center is a powerful, automated system that performs multiple machining operations under one setup. It boosts speed, precision, and repeatability while cutting down on manual tasks.

Used across industries like aerospace, automotive, and mold making, these machines make modern precision manufacturing possible — and profitable.