Are you ever curious how modern factories make exact parts fast? CNC manufacturing makes that possible with machines and smart control.

CNC manufacturing means using computer‑controlled machines to cut, shape, or drill materials with high precision. It replaces manual tools and mistakes with steady accuracy.

I encourage you to read on. You will learn how CNC works, why many factories choose it, what items use CNC parts, and where CNC happens in the world.

How does CNC support manufacturing?

Many parts need tight precision. CNC helps solve that problem quickly and reliably.

CNC supports manufacturing by turning digital designs into exact physical parts. It reduces human error, boosts repeatability, and speeds up production for complex shapes.

CNC stands for Computer Numerical Control. In CNC manufacturing, a computer reads a design file. Then it tells a machine how to move tools. The tools cut or shape materials like metal, plastic, or wood. This process happens step by step. The computer controls tool speed, direction, and depth. That gives high accuracy. It also gives consistent results even after many parts.

Why digital design matters

Designers use CAD (computer‑aided design) software. They draw the part in the software. They save the drawing as a file (for example, G‑code or similar). CNC machines read that file. The machine moves automatically. This avoids manual measurements or adjustments. It also makes complex shapes possible. The shapes may have curves, angles, holes, or tight tolerances. CNC handles those easily.

Repeatability and quality control

When a human carves or drills a part by hand, variation happens. Each part may differ slightly. With CNC, every part can be just like the first one. If you need 100 identical parts, CNC can deliver them with minimal variation. This helps in quality control. It reduces waste and lowers costs over many parts.

Efficiency and speed

CNC speeds up tasks. Once the design is ready and machine set up, the parts come out without constant supervision. The machine can run many hours. It can run overnight. That helps factories meet demand. It also frees workers to do other tasks.

In short, CNC acts as a bridge between design and real part. It turns ideas into physical objects. It keeps accuracy, repeatability, and speed. That supports modern manufacturing at large scale.

Why automate manufacturing with CNC?

Manual work often slows down production and causes errors. Automation through CNC removes these limits.

Factories choose CNC automation because it lowers cost, increases speed, improves precision, and handles complex designs that manual tools cannot manage.

Automating manufacturing with CNC gives many benefits. First, it reduces human labor. When machines run, fewer workers are needed. That lowers labor cost. It also lowers risk of mistakes. People may lose focus or mismeasure. Machines do not have those problems.

Second, CNC machines work long hours. They do not tire. They can run 24/7 if needed (with proper maintenance). This increases output. Factories meet large orders faster.

Third, automation gives consistent quality. Every part matches the original design exactly. For industries like aerospace, automotive, or electronics, consistency is critical. A small error can ruin the whole product. CNC cuts that risk.

Fourth, CNC handles complicated parts well. Some parts have intricate shapes, small holes, tight tolerances, or complex curves. Manual tools struggle or take too long. CNC excels in those tasks.

Fifth, CNC provides flexibility. When design changes, engineers update the digital file. Then the machine can produce the new version without new hard tools. This reduces tooling cost and time. It suits prototyping and small batch orders.

Finally, CNC helps with safety. Manual machining may expose workers to hazards (sharp tools, heavy lifting, repetitive motion). Automation moves risk to machine side. Workers supervise or load/unload parts, which is safer.

When manufacturing volume grows, manual methods become slow and costly. CNC automation solves that. It makes production stable, predictable, and efficient.

Which products rely on CNC?

Many everyday products come from CNC‑made parts. We see those parts in cars, gadgets, and building materials.

Products like automotive components, metal frames, electronics housings, machine parts, furniture hardware and even solar panel frames often depend on CNC manufacturing for precision and consistency.

CNC manufacturing supports a wide array of products. Here is a table showing common product categories and typical CNC‑made parts:

| Product Category | Typical CNC‑Made Parts | Why CNC Is Needed |

|---|---|---|

| Automotive | Engine blocks, gear parts, mounting brackets, brake components | High strength, tight tolerances |

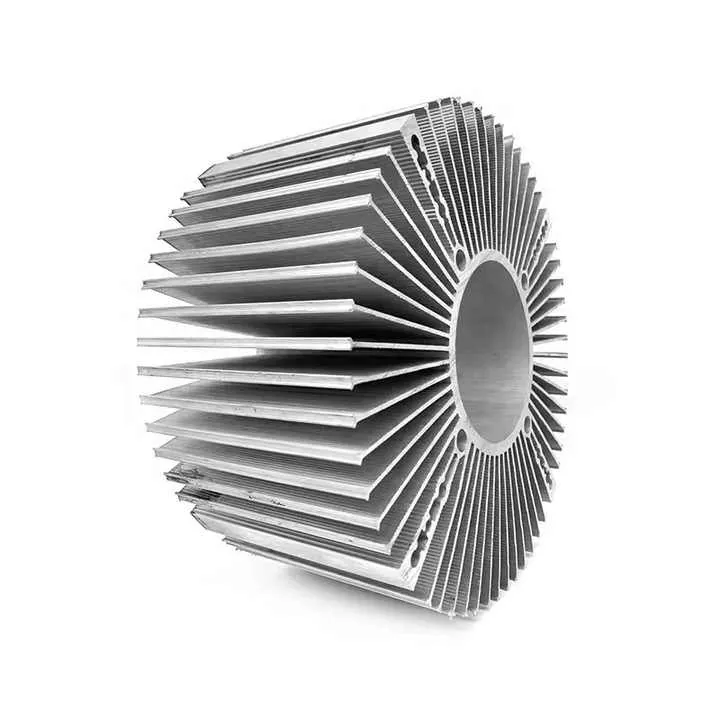

| Electronics & Gadgets | Housings, heat sinks, internal frames | Complex shapes, fine details |

| Machinery & Tools | Shafts, gears, machine bases, custom fixtures | Durable metal parts, repeatability |

| Furniture & Fixtures | Metal joints, brackets, hinges, profiles | Clean look, precise fit |

| Construction / Solar | Window/door frames, solar panel frames, railings | Long profiles, structural strength |

| Aerospace & Defense | Aircraft parts, precision components | Extreme precision, safety standards |

CNC helps each product by shaping metal or plastic with exact measurements. For example, car engine parts must fit and work under high pressure and heat. CNC ensures each part meets design specs.

Electronics devices often need slim, compact, durable housings. CNC cuts materials with tight tolerances so components fit perfectly. Sometimes designs change quickly. CNC allows fast updates without new tools.

In furniture or fixtures, CNC gives clean edges, consistent sizes, and good finish. That improves appearance and assembly. For buildings or solar frames, CNC produces long aluminum profiles with accuracy. These profiles fit together well at installation sites.

In heavy machinery or tools, CNC ensures parts are strong and consistent. Machines rely on parts working precisely together. If one gear or shaft is off by small amount, whole machine can fail. CNC reduces that risk.

Because of these needs, many industries depend on CNC manufacturing. It delivers quality, consistency, and flexibility across many product types.

Where is CNC manufacturing used?

CNC manufacturing does not stay in one place. It is used in many factories, factories in many countries. It shapes global production.

CNC manufacturing is used worldwide in automotive, aerospace, electronics, construction, energy, and custom‑machining shops. It supports both mass production and small batch work.

CNC use shows up in many industries all over the world. Here are main industry sectors and how they use CNC:

| Industry | Typical Use of CNC Manufacturing |

|---|---|

| Automotive | Engine parts, chassis components, interior metal parts |

| Aerospace / Defense | High‑precision parts for aircraft, drones, engines |

| Electronics / Technology | Housings, frames, heat sinks, small metal or plastic parts |

| Construction / Architecture | Metal profiles, window frames, railings, structural components |

| Energy / Renewable Energy | Frames for solar panels, wind‑turbine components, support structures |

| Industrial Machinery | Machine parts, fixtures, custom metal parts |

| Custom Manufacturing Shops | One‑off prototypes, spare parts, small batch orders |

CNC fits both large and small companies. Big factories use CNC for mass parts. Small shops use CNC to make custom parts or prototypes. CNC machines exist in many countries. They appear where demand for precision or metal shaping is strong.

Global reach and types of users

Some users are big automakers or aircraft companies. They need thousands of identical parts. CNC gives that. Others are custom shops. They need one or few parts fast. CNC also gives that.

Many countries import raw aluminum or steel. Then they build parts with CNC. Some supply parts globally. Others focus on local markets. CNC lets them meet quality standards.

Role in custom and prototype work

When designers create new products, they start with prototypes. CNC allows building prototypes quickly. Then they test and adjust designs. After tests, CNC helps make final parts. This process reduces cost and time for product development.

Support for industrial supply chains

Parts from CNC factories often become components in bigger systems. For example, an aluminum profile made for solar frames may ship to a solar plant in a different country. CNC manufacturing supports global supply chains.

Conclusion

CNC manufacturing turns digital designs into real parts accurately and fast. It works across many industries and products. It offers precision, repeatability, flexibility, and efficiency. CNC helps modern factories meet demand while keeping quality high.