Metal shaping can feel like magic when you press a button and see a perfect piece appear. But what makes that possible?

CNC parts are the individual components used by CNC machines to shape metal or other materials. They include tool holders, motors, spindles, and frames. Together they make precise cuts and shapes with computer control.

To understand CNC parts better, I will explain how they work. Then I will show why they matter, which parts wear quickly, and where you can find them.

How do CNC parts function?

Making complex shapes by hand is slow and hard. CNC machines make that easy with the help of many smart components.

CNC parts work by holding tools, driving motion, and guiding material. They make CNC machines cut or shape material based on digital designs.

When a CNC machine runs, it reads a program called G-code. That code tells the machine where to move and how fast. Motors and spindles turn the tools. Rails and guides help the parts move straight. The machine holds the material firmly while shaping it.

Key parts of a CNC system

| Component | Function |

|---|---|

| Machine frame | Holds all other parts in place |

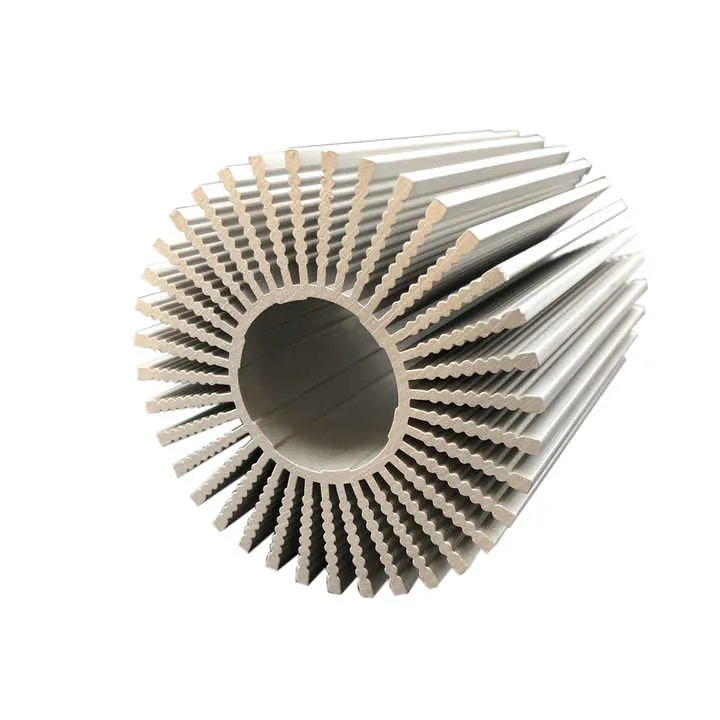

| Spindle and tool holder | Spins the cutting tools at high speeds |

| Servo/Stepper motors | Move the tool or table precisely |

| Linear guides and rails | Keep movements smooth and straight |

| Controller (computer) | Sends commands to all moving parts |

The frame keeps everything steady. The spindle spins the cutter and is connected to a tool holder. Motors move the tool head or the table on the X, Y, and Z axes. Rails guide the motion so it stays straight. The computer sends instructions to each motor in real time.

This system lets the machine make accurate shapes again and again. That’s how you get perfect parts every time.

Why are CNC components essential?

A CNC machine without quality parts is like a car with loose wheels—dangerous and unreliable.

Good CNC components let machines run smoothly and accurately. They ensure parts fit design exactly and reduce waste.

Each component plays a critical role. If the spindle shakes, the cut is bad. If the guide rail sticks, the shape is wrong. If the motor skips, the tool moves to the wrong place. All of this ruins your part and wastes time and materials.

Modern industries depend on this precision. Car makers, electronics factories, and aerospace companies need reliable machines that make the same part hundreds of times. CNC parts are what make this possible.

Also, they help reduce errors. Less scrap means lower cost. And the same setup can make different parts—just change the code. That makes CNC flexible and fast.

Which CNC parts wear fastest?

CNC machines work hard. Over time, some parts wear out from constant use.

Parts that move a lot or cut hard material often wear out first. That includes bearings, spindles, tool holders, guide rails, and belts.

Some CNC components face more stress than others. Parts that rotate or move often, especially under heavy loads, wear out faster. Heat, friction, and vibration all cause damage over time.

Common wear parts and why they fail

| CNC Part | Cause of Wear | Symptoms |

|---|---|---|

| Spindle bearings | High-speed rotation, heat | Noise, tool chatter, rough finish |

| Tool holders | Frequent tool changes | Poor grip, misalignment |

| Guide rails | Constant movement, dust buildup | Jerky motion, inaccurate cuts |

| Belts and pulleys | Tension, age, and vibration | Slippage, missteps |

| Cooling systems | Continuous flow and contamination | Leaks, overheating |

Bearings take the most heat and pressure, especially in the spindle. They start to vibrate or make noise as they wear. Tool holders can lose grip, which makes cuts less precise. Rails and guides need cleaning and lube to avoid jamming. Belts stretch over time and must be checked regularly.

Cleaning and maintenance help. I always wipe down my rails, keep spindles cool, and replace filters and belts on schedule. That way, the machine stays in top shape and avoids sudden failure.

Where to source CNC parts?

Finding CNC parts is easier when you know where to look and what you need.

You can get CNC parts from specialized manufacturers, authorized suppliers, or used‑part sellers. You pick based on need, budget, and lead time.

When a part fails or wears out, quick replacement is key. Here are some places to buy:

Where to buy CNC parts

| Source | Advantages | Disadvantages |

|---|---|---|

| OEM (original makers) | Exact fit, high quality | Expensive, slow shipping |

| Authorized distributors | Good stock, brand options | May have limited selection |

| Aftermarket suppliers | Cheaper, sometimes more flexible | Mixed quality, may not fit well |

| Used/refurbished sellers | Low cost, fast delivery | Risk of defects, no warranty |

I often use OEM parts for key items like spindles or motors. They last longer and work better. For smaller things like filters, belts, or switches, aftermarket parts work fine. Used parts are okay for non-critical systems, but I test them first.

Online catalogs help compare options. I also speak with technical reps to make sure the specs match. And I keep spares of parts that