CNC punching sounds technical, but it’s shaping industries worldwide. If you work with metal and need precise cuts and holes, you’ll want to understand how this process works.

CNC punching is a computer-controlled metal fabrication method that uses a punch press to create holes, shapes, or indentations in sheet metal with speed and accuracy.

Modern manufacturing needs speed, consistency, and precision. CNC punching delivers all three, making it a go-to solution in industries from automotive to electronics. Let’s break it down and see what makes CNC punching so powerful.

How does CNC punching work?

Metal shaping used to be manual, slow, and inconsistent. That changed with automation, and CNC punching is now a key part of modern fabrication.

CNC punching works by using a computer-controlled turret press that punches precise holes into metal sheets based on a digital design file.

The process starts with a CAD file. This digital drawing defines where each hole or shape goes. The file gets uploaded into a CNC (Computer Numerical Control) machine. This machine reads the coordinates and sends commands to a punching head.

Key Components of CNC Punching:

| Component | Function |

|---|---|

| CNC Controller | Processes CAD data into machine movements |

| Turret | Holds multiple punching tools |

| Punching Head | Moves to position and punches the metal |

| Sheet Clamp | Secures the metal sheet in place |

The turret contains various punching tools. As the machine moves across the sheet, it quickly switches tools to match the hole shapes or cuts needed. Punching pressure is high, so accuracy must be perfect.

Depending on the machine’s configuration, it can punch:

- Circular holes

- Rectangular or custom shapes

- Louvers or dimples

- Embossed marks for branding

The main benefit here is automation. A full sheet can be processed in minutes, with no manual adjustments. The machine follows a set path with no deviation, ensuring uniform quality.

Workflow Overview:

- Design creation – CAD or CAM software

- Machine setup – Load tools and material

- CNC programming – Upload file and verify path

- Punching operation – Automated tool changes and punching

- Post-processing – Cleaning, deburring, finishing

CNC punching can also be combined with forming operations like bending and countersinking. Some machines offer multitasking capabilities, reducing the need for secondary steps.

Why choose CNC punching for metalworking?

Metalworking often comes with high expectations: precision, repeatability, and low waste. Manual methods struggle to deliver all three.

CNC punching is ideal for metalworking because it offers high-speed, accurate, and repeatable results for complex patterns and large volumes with minimal waste.

CNC punching provides several advantages over traditional methods, especially in sheet metal fabrication. It removes guesswork, speeds up delivery, and ensures each part meets the same high standard.

Key Benefits of CNC Punching

| Advantage | Explanation |

|---|---|

| Precision | Tolerance levels often reach ±0.1mm |

| Speed | Fast cycle times, ideal for large orders |

| Cost-Efficiency | Reduced labor and material waste |

| Flexibility | Handles various designs with minimal setup changes |

| Automation | CAD to final part with minimal human intervention |

Scenarios Where CNC Punching Outperforms:

- Repetitive manufacturing: same shape punched hundreds or thousands of times

- High-complexity designs: multiple cutouts and forms per part

- Short lead times: design to production in hours

- Cost-sensitive projects: high material efficiency, low scrap

Unlike laser cutting or waterjet, CNC punching can perform both cutting and forming. This means parts can be embossed, louvered, or countersunk—all within the same setup.

Also, CNC machines can punch thicker sheets than some alternative cutting technologies. For example:

| Material Thickness | Process Feasibility (Punching) |

|---|---|

| Up to 6mm (steel) | ✅ Yes |

| Up to 5mm (aluminum) | ✅ Yes |

| Up to 3mm (stainless) | ✅ Yes |

So, if your project requires fast, repeatable hole-making or forming in metal sheets, CNC punching is hard to beat.

Which materials are suited for CNC punching?

Using the wrong material in a CNC punch can damage tools or ruin precision. Knowing which materials perform best is key.

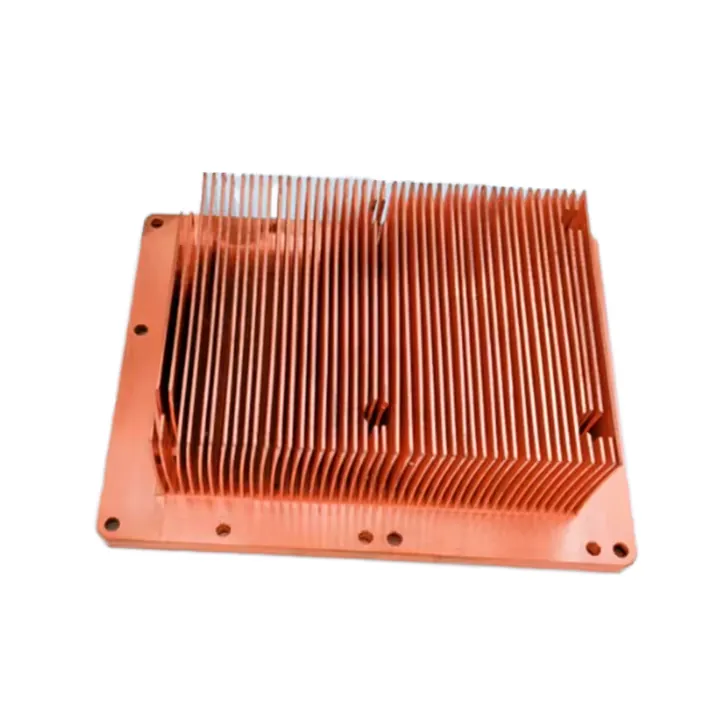

CNC punching works best on ductile, flat sheet metals such as aluminum, steel, stainless steel, copper, and brass.

Punching involves pressure and force. That’s why ductile and softer metals are preferred—they deform without cracking and spring back less, which helps keep hole sizes accurate.

Commonly Used Materials in CNC Punching

| Material | Characteristics | Typical Thickness |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | 1–5 mm |

| Mild Steel | Strong and easy to work with | 1–6 mm |

| Stainless Steel | Tough, corrosion-resistant | 1–3 mm |

| Copper | Conductive, soft | 1–3 mm |

| Brass | Easy to punch, decorative finish | 1–3 mm |

Each material comes with its own challenges:

- Stainless steel can wear out punching tools faster

- Copper and brass can leave residues that need cleaning

- Thick steel may require stronger machines or multiple punches

Key Considerations:

- Sheet thickness – Too thick may exceed tool capacity

- Hardness – Harder metals dull tools faster

- Springback – Affects precision of punched features

- Surface finish – Important for visible or cosmetic parts

Tooling must also match the material. For example, aluminum is softer, so tools last longer. But with stainless steel, frequent tool sharpening or carbide tools may be needed.

If you’re working with alloys or coated materials, talk with your supplier about compatibility before punching. Some coatings can crack or peel under pressure.

Where is CNC punching applied?

CNC punching is more than just holes—it’s a full manufacturing solution used across industries.

CNC punching is widely used in industries such as construction, electronics, automotive, and industrial machinery to produce parts like brackets, panels, and enclosures.

From your car’s dashboard to the electrical panel in your building, CNC punched components are everywhere. The process suits both structural and decorative parts, combining form and function.

Common Applications:

| Industry | Typical Parts Made |

|---|---|

| Construction | Wall panels, ceiling grids, HVAC brackets |

| Electronics | Control panels, switch plates |

| Automotive | Interior panels, support brackets |

| Industrial Equipment | Machine housings, mounting plates |

| Furniture | Shelves, frames, drawer slides |

How CNC Punching Adds Value:

- Consistency: Each hole is the same, every time

- Integration: Holes, dimples, and marks in one process

- Branding: Logos or text can be embossed directly

- Scalability: Easy to scale from prototype to mass production

For example, in the solar energy sector, punched aluminum frames are used to support panels. These frames need perfect alignment and fast production. CNC punching makes it possible to mass-produce frames that are identical, strong, and corrosion-resistant.

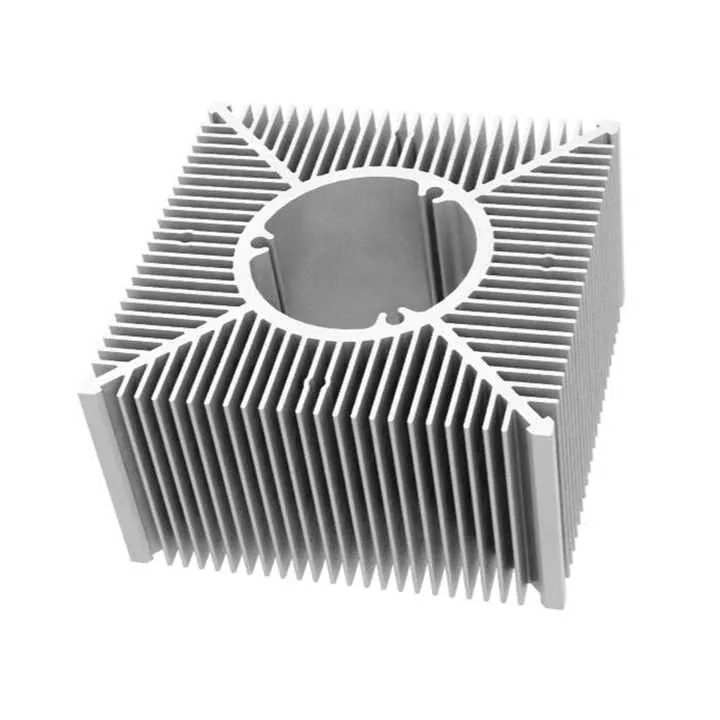

In consumer electronics, thin metal enclosures must be ventilated without compromising strength. CNC punching allows small ventilation holes with tight tolerances.

Special Use Case: Lighting Industry

In the lighting industry, aluminum profiles often need custom holes for LED strips or connectors. CNC punching allows rapid customization per client need, which speeds up both design and installation.

Conclusion

CNC punching transforms flat metal into functional parts quickly and precisely. It's fast, repeatable, and ideal for everything from simple brackets to complex electrical enclosures. For projects needing tight tolerances and quick turnaround, CNC punching remains a trusted choice.