A CNC router machine is a powerful tool that can shape wood, metal or plastic with exact cuts. It helps makers get clean, repeatable results without hard manual labor.

A CNC router machine uses computer‑controlled movement along multiple axes to cut or carve materials. This lets it follow precise designs and deliver consistent shapes every time.

CNC routers offer a mix of speed, accuracy, and flexibility. They lower manual error and let manufacturers produce complex parts efficiently. Read on to learn how they work, why they matter, what they cut, and where they shine.

How does a CNC router machine operate?

A CNC router makes cuts by following computer instructions on its axes. It moves a tool bit very precisely to shape materials.

The machine reads a digital design file and turns it into physical tool paths. Then it moves a cutting tool along those paths to carve or mill the material exactly as planned.

When a project begins, designers create a 2D or 3D model using CAD (computer‑aided design) software. The model defines the shape, depth, and edges needed. Then CAM (computer‑aided manufacturing) software converts that model into a set of instructions. These instructions guide the CNC router on where to move, how fast, and how deep to cut.

Key Steps of Operation

- Design Creation: The user draws a part in CAD software.

- Tool Path Generation: CAM software converts that drawing to tool paths with speeds and depths.

- Machine Setup: The workpiece is fixed on the router bed. The appropriate cutting tool (bit) is installed.

- Execution: The router executes the tool paths automatically. The tool moves along X, Y, and sometimes Z axes. The spindle spins and cuts the material.

- Finishing: The part is removed and cleaned up if needed.

Here is a table of the main components of a typical CNC router:

| Component | Function |

|---|---|

| Controller & Computer | Interprets the CAD/CAM file and sends movement commands |

| Stepper/Servo Motors & Rails | Move the router along X, Y (and Z) axes precisely |

| Spindle & Cutting Bit | Spins and cuts material according to design |

| Work Bed / Clamps | Hold the material firmly in place during cutting |

| Software (CAD + CAM) | Create the design and convert to tool paths |

The controller and computer are like the brain. They read the design file and tell the motors where to move. The software defines the path, speed, and depth. The motors drive rails so that the cutting tool moves exactly. The spindle spins fast so the cutting bit can carve the material. Clamps or vacuum hold the material so the bit does not shift or slip.

When the job runs, the CNC router may cut on multiple axes. The common axes are X (left‑right), Y (forward‑back), and Z (up‑down). Some advanced routers support extra axes or tilting heads for angled cuts. The precision of the movement gives very clean edges and uniform cuts across multiple parts.

Because everything is controlled by computer, you can repeat the exact same cut over and over. That removes human error and speeds up production. Even complex shapes or curved paths are easy.

In some setups, the machine also supports tool changes: the router can swap bits automatically to perform drilling, cutting, engraving in one run. That adds flexibility and saves time.

Overall, a CNC router translates a digital design into physical form by precisely controlling motion and cutting tools. Its automated process improves quality, consistency, and speed.

Why are routers vital for precision cutting?

Cutting materials by hand is slow, inconsistent, and often imprecise. A router solves those problems.

Routers deliver high accuracy and repeatability in cutting. They ensure each part matches design exactly. That makes them key for quality parts.

Human hands cannot match the precision or uniformity of a CNC machine. Even skilled craftsmen vary slightly from part to part. With a CNC router, the same design yields identical pieces every time. That matters a lot when parts need to fit, assemble, or align perfectly.

Why Precision and Consistency Matter

- Fit and Assembly: Many parts must join together tightly. Even small errors cause misfit or weak joints.

- Surface Quality: Clean edges, smooth curves, sharp corners — CNC routers cut clean. That lowers sanding or finishing work.

- Repeat Production: Factories often produce dozens or hundreds of identical items. CNC routers guarantee uniform output.

- Complex Designs: Curves, intricate shapes, engravings — CNC routers handle these with ease.

Benefits Over Manual Cutting

- Speed – Router cuts much faster than manual saws or chisels.

- Less Waste – Precise cuts reduce material waste. Mistakes drop.

- Repeatability – Each part matches the design exactly.

- Detail Work – Fine grooves, curves, pockets or lettering are possible.

Because CNC routers cut exactly as per digital design, engineers and designers can trust that final parts will meet specifications. That matters for structural parts, mechanical parts, and custom pieces.

Also, since the process is automated, parts can be produced with fewer people and less manual labor. That reduces cost per piece and shortens production time.

In many industries — furniture, signage, prototype making, cabinetry — precision and repeatability determine whether a part will behave or look as expected. Without precise cutting, many designs fail in fit, function, or finish.

In short, CNC routers turn design ideas into precise real-world parts. That makes them vital for any work needing repeatable, accurate, clean cutting.

Which materials can routers process?

Routers can cut many types of materials. They work on wood, plastics, metals and composites.

Typical materials processed by routers include softwood and hardwood, plastics like MDF or acrylic, aluminum, and even some soft metals. This flexibility makes them useful in many fields.

Common Materials for CNC Routing

| Material Type | Examples |

|---|---|

| Wood | Pine, oak, plywood, MDF, hardwood |

| Plastics | Acrylic, PVC, HDPE, composite sheets |

| Metals (soft) | Aluminum, brass, copper |

| Composites & Others | Laminates, foams, resin boards |

Routers process wood easily because wood machines well. Cuts are clean, edges smooth. Hardwood and softwood both work. Veneer boards or plywood also work if clamped well.

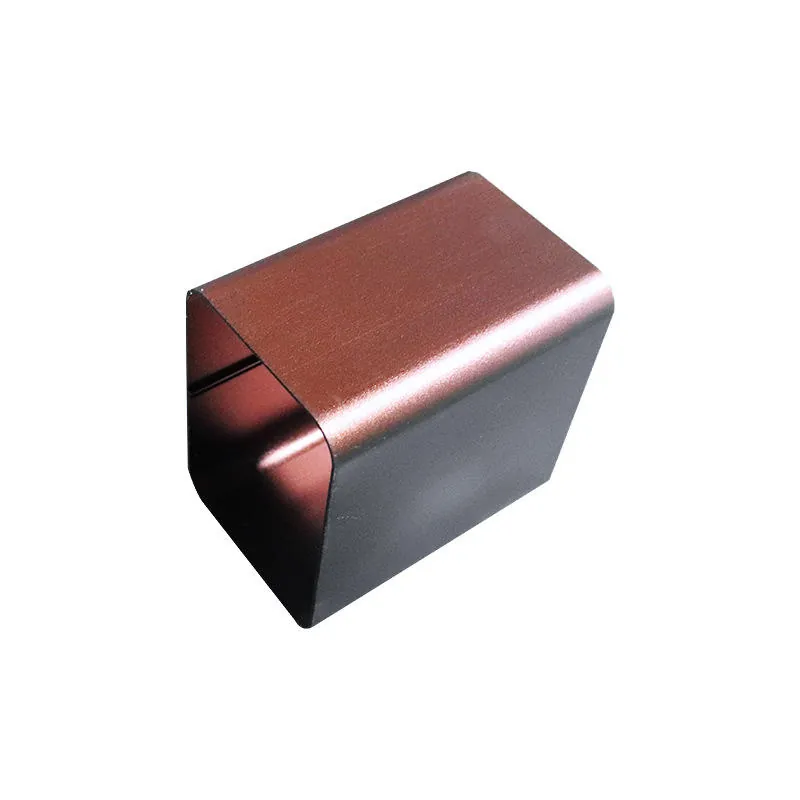

Plastic boards like acrylic or PVC cut cleanly. Router bits must suit the material to avoid melting or chipping. For plastics, using slower speed and proper bit helps. Some plastics need finishing to smooth edges after cutting.

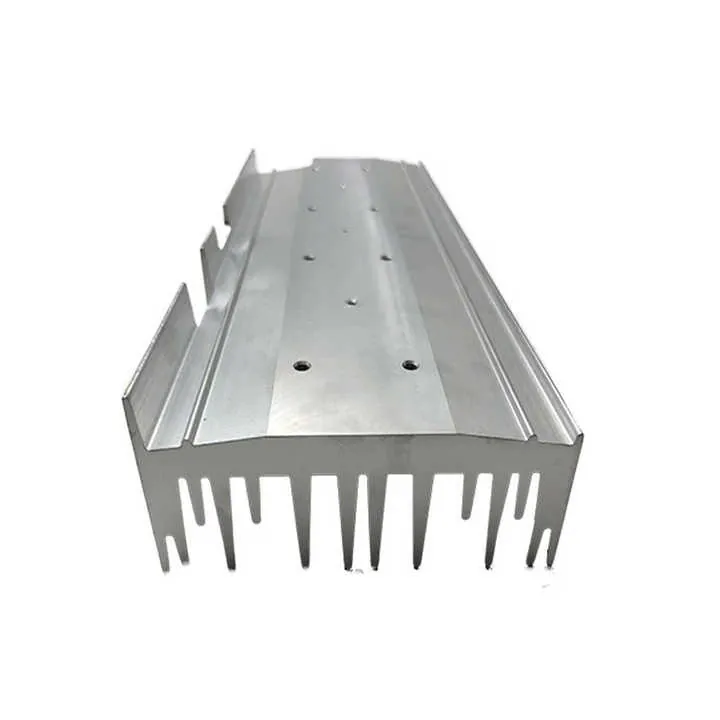

Soft metals like aluminum or brass also work. However, metal cutting requires a strong spindle, rigid frame, and sometimes coolant or dust collection. The bit must be designed for metal. Cuts in metal are slower and need careful setup.

Composites and resin boards — such as laminate boards or resin-infused material — also run well on CNC routers. They expand the range of possible products.

What Limits the Material Choice

Some materials do not suit CNC routers. Hard metals like steel or cast iron need special machines. Also very thick or heavy blocks may exceed the router’s bed capacity. Materials that produce harmful dust might need special dust collection or safety gear.

Soft, non‑brittle materials give best results. Brittle materials may chip or crack if clamping or bit selection is improper. Materials with uneven density or insertions can cause uneven cuts.

When choosing material, you must match tool bit, router power, and clamping method. For metals, ensure rigidity and use proper feed rate. For plastics or composites, control cut speed and take care of dust or fumes.

Because routers accept many materials, they serve woodworking shops, sign makers, metal‑frame producers, prototype labs. This versatility gives companies a broad range of product options without investing in many machines.

Where are CNC routers most effective?

Routers shine where makers need flexibility, precision, and repeatability. They fit many industries and tasks.

CNC routers are most effective in industries such as furniture making, sign‑making, cabinetry, metal framing, prototyping, and custom manufacturing. They speed up work and raise quality.

Common Use Cases

- Furniture and Cabinet Making – Cutting panels, creating joints, carving decorative edges.

- Sign Making and Engraving – Cutting plastic or wood signs with letters or shapes.

- Prototyping and Product Development – Making custom parts fast for tests or design reviews.

- Metal Framing and Light Metal Parts – Cutting aluminum parts for assemblies, frames, etc.

- Custom Items and Art Pieces – Crafting decorative panels, molds, shapes with curves or complex geometry.

Because the machine reads digital designs, it's great for custom jobs. When a project is unique or changes often, CNC router suits better than fixed tools. Setup is quick and no special molds or dies are needed.

Strengths that Make Them Effective

Speed and Volume

Once design is ready, router can run many parts automatically. That boosts productivity.

Customization and Flexibility

Changing design just needs a new digital file. No physical tool change needed (except bit sometimes).

Cost‑Effectiveness

For small to medium batches, using a CNC router costs less than setting up expensive molds or special tools.

Precision for Assembly

When parts need to fit together or match tight tolerances, router ensures each piece matches spec.

Lower Waste and Less Labor

Material use is efficient. Fewer workers needed. Mistakes are fewer.

You might ask where router is not effective. Heavy steel beams or large structural parts often need different machines. Very large single pieces may exceed bed size. For high‑volume production of identical steel or heavy items, other machines work better.

Still, for a wide range of materials and job sizes, CNC routers offer the best mix of speed, quality, and flexibility. They serve small workshops and big factories alike.

Conclusion

CNC routers turn digital designs into real parts with high precision, speed, and flexibility. They process wood, plastic, soft metal, composites. They help in furniture, metal framing, prototyping and custom work. For many jobs, they offer unmatched value.