Manufacturers need accurate, efficient ways to shape materials. CNC routing solves that problem, but many people still don’t know how it works or why it matters.

CNC routing is a subtractive manufacturing process that uses computer-controlled machines to cut, carve, and shape materials like wood, plastic, or metal into precise components.

This method combines speed, flexibility, and accuracy—making it essential for industries that require consistent results and fast turnaround.

How does CNC routing work?

Many think CNC routing is complicated, but it simply replaces hand tools with automation. Once you understand the steps, the entire process becomes easy to follow.

CNC routing works by converting digital design files into G-code instructions that control the movement of the router head along the X, Y, and Z axes to cut materials accurately.

The process starts with a design created in CAD software. That file is then processed in CAM software to generate G-code. The G-code tells the CNC router how to move—where to cut, how fast, and how deep.

Key Steps in CNC Routing

- Design File Creation: Drawings made using CAD software like AutoCAD or Fusion 360.

- Toolpath Generation: CAM software converts drawings into motion commands.

- Machine Setup: Material is secured to the table, and the router is zeroed.

- Cutting Process: The machine follows the programmed toolpath.

- Finishing: Clean-up, sanding, or polishing, depending on material.

Main CNC Router Components

| Component | Function |

|---|---|

| Spindle | Spins the cutting bit at high speed |

| Gantry | Moves the spindle in X/Y directions |

| Bed/Table | Supports and holds the material |

| Controller | Sends signals to motors and spindle |

| Software | Handles design input and G-code output |

The router moves in three directions:

- X-axis: Left to right

- Y-axis: Front to back

- Z-axis: Up and down

By following these paths, the machine cuts or engraves the design into the material.

Why use CNC routing for cutting and shaping?

Cutting and shaping materials by hand is time-consuming and inconsistent. CNC routing brings a level of accuracy and speed that manual processes simply can’t match.

CNC routing is preferred because it delivers repeatable precision, fast production speeds, and the ability to cut complex shapes in a wide range of materials.

CNC routing doesn't rely on operator skill alone. Once programmed, the machine executes the job the same way every time. This is critical in industries where parts need to be consistent—like cabinet making or automotive prototyping.

Key Advantages of CNC Routing

- Accuracy: Tolerances as tight as ±0.01mm

- Repeatability: Identical parts in mass production

- Speed: Processes materials faster than manual tools

- Complexity: Cuts curves, pockets, and 3D surfaces easily

- Material Efficiency: Optimized layouts reduce waste

Manual vs CNC Routing

| Factor | Manual Method | CNC Routing |

|---|---|---|

| Speed | Slower | Much faster |

| Skill Dependency | High | Low once programmed |

| Precision | Variable | Very consistent |

| Cost Over Time | Higher labor | Lower per unit |

| Scalability | Limited | Ideal for mass production |

From signs to machine components, CNC routers cut down production time, reduce labor costs, and improve quality.

Which materials can be routed by CNC?

Some think CNC routers are only for soft materials. In reality, they can handle a wide variety—from foam to metal—if configured correctly.

CNC routers can route wood, plastic, aluminum, foam, and composites, making them ideal for both lightweight projects and complex industrial applications.

Material choice affects tool type, speed, and cooling needs. Soft materials like foam cut quickly, while metals require slower feeds and more robust tooling.

Common CNC Routing Materials

Wood Types

- Hardwood: Oak, walnut—used in furniture.

- Softwood: Pine, fir—good for quick cuts and signage.

- Plywood/MDF: Stable and cost-effective for cabinetry.

Plastics

- Acrylic: Ideal for displays and light diffusion.

- PVC: Good for signage and indoor panels.

- HDPE/Polycarbonate: Tougher plastics for enclosures.

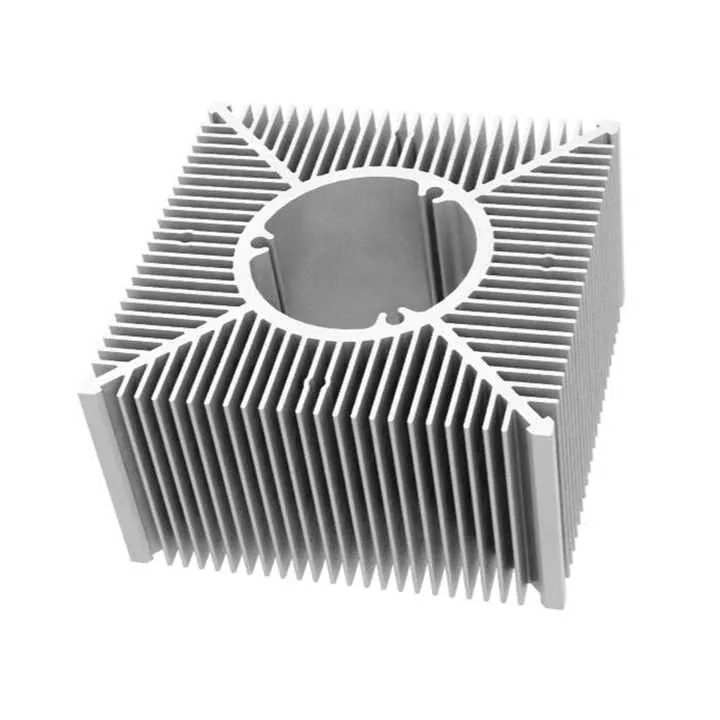

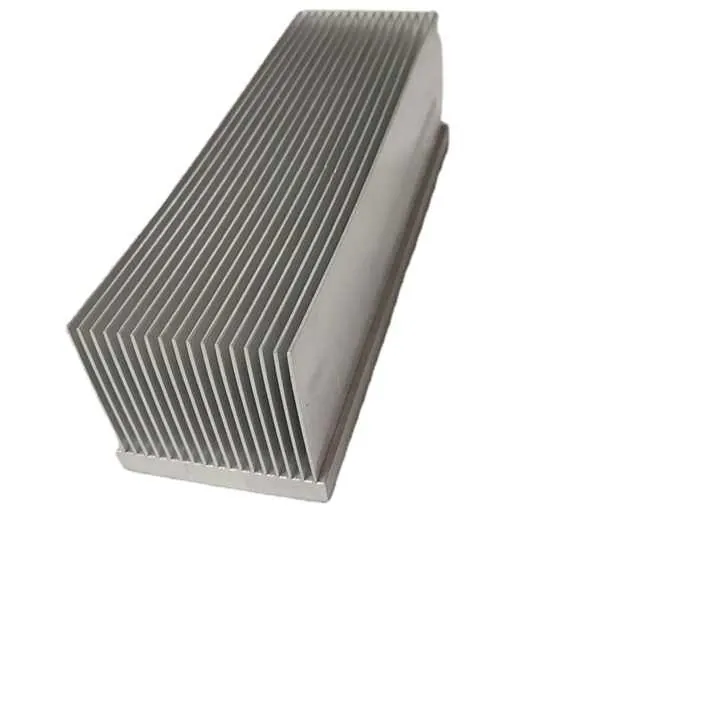

Metals

- Aluminum: Most common metal for CNC routing.

- Brass/Copper: Routed occasionally with proper bits.

Others

- Foam: Lightweight and used for mockups and insulation.

- Composites: Like aluminum composite panels (ACP), common in construction.

CNC Material Performance Table

| Material | Routing Ease | Best Uses |

|---|---|---|

| MDF | ✅ Very easy | Furniture panels, doors |

| Acrylic | ✅ Easy | Signs, lighting, displays |

| Aluminum | ⚠ Moderate | Brackets, panels, frames |

| Foam | ✅ Very easy | Mockups, insulation, packaging |

| Composite Panel | ✅ Easy | Wall cladding, signage |

CNC routers offer flexibility. Switching from plastic to wood or even aluminum just takes a bit change and software adjustment. That’s why they’re so popular across industries.

Where is CNC routing applied?

Many still think CNC routing is limited to woodworking. But it’s used in everything from aircraft parts to promotional signs.

CNC routing is used in furniture manufacturing, signage, aerospace, automotive, architecture, and packaging—anywhere materials need precise cutting or engraving.

Anywhere high accuracy and repeated designs are needed, CNC routing plays a role. Its versatility allows a single machine to serve multiple departments within a company.

Industry Applications

1. Furniture and Cabinets

Routing MDF and plywood into door fronts, drawers, and shelves is a core application. CNC routers enable mass customization, where every client gets a unique design.

2. Sign Making and Branding

Plastic, foam, and metal are shaped into letters, logos, and 3D signs. CNC routing ensures that curves, fonts, and spacing are perfect every time.

3. Aerospace and Automotive

Lightweight aluminum parts like brackets, covers, and interior frames are routed to exact sizes. Accuracy is critical for safety and performance in these fields.

4. Architecture and Construction

Aluminum composite panels are routed to fit building façades. Intricate wall decorations or stair panels are cut quickly and accurately.

5. Prototyping and R&D

R&D teams route foam or plastic to test new product ideas. They can quickly change designs and run tests without needing expensive molds or dies.

6. Electronics and Enclosures

Plastic or aluminum boxes with precise holes for switches, connectors, and displays are common outputs. CNC routing simplifies low-volume, high-precision part creation.

Table: Common Uses by Industry

| Industry | CNC Routed Products |

|---|---|

| Furniture | Cabinets, doors, decorative panels |

| Advertising | 3D signs, light boxes, channel letters |

| Aerospace | Panels, structural supports, enclosures |

| Automotive | Dashboards, trim, custom panels |

| Construction | ACP cladding, window profiles, signage |

| Electronics | Custom casings, faceplates, connector slots |

CNC routing makes it possible to take digital designs and bring them to life in almost any material, with little room for error.

Conclusion

CNC routing is more than just automated cutting—it’s a flexible, powerful method for producing consistent, accurate parts across many industries. It works on materials from wood to aluminum and fits businesses from workshops to high-tech factories.