Many manufacturers struggle to produce accurate cylindrical parts quickly. CNC turning solves this by using automation to reduce errors and increase speed.

CNC turning is a computer-controlled machining process that removes material from a rotating workpiece using cutting tools, creating precise cylindrical shapes.

This article explains how CNC turning works, why it's important, which materials work best, and what factors affect precision.

How does CNC turning shape cylindrical parts?

Machining round parts manually is time-consuming and inconsistent. Operators often face tool wear, measurement errors, and variations in speed.

CNC turning creates cylindrical parts by rotating the material while a stationary cutting tool moves in programmed paths to remove excess material.

CNC turning works by mounting a workpiece on a spindle, which rotates at high speed. A cutting tool, mounted on a turret or tool post, moves along the X and Z axes. As the tool moves, it removes layers of material from the spinning part. This process is automated and follows exact design specifications from a CAD file.

The turning process step-by-step

- Setup: Clamp the workpiece in a chuck.

- Programming: Input G-code that controls the cutting path.

- Rotation: The spindle rotates the workpiece.

- Tool engagement: Tools move into position and begin cutting.

- Finishing: The machine performs rough and fine cuts to meet final dimensions.

Types of turning operations

| Operation | Description |

|---|---|

| Facing | Creates a flat surface at the end of the part |

| Straight turning | Reduces the diameter along a fixed length |

| Taper turning | Produces a conical shape |

| Grooving | Cuts a slot along the circumference |

| Threading | Forms threads by precise tool movement |

| Parting | Cuts the piece off from the stock |

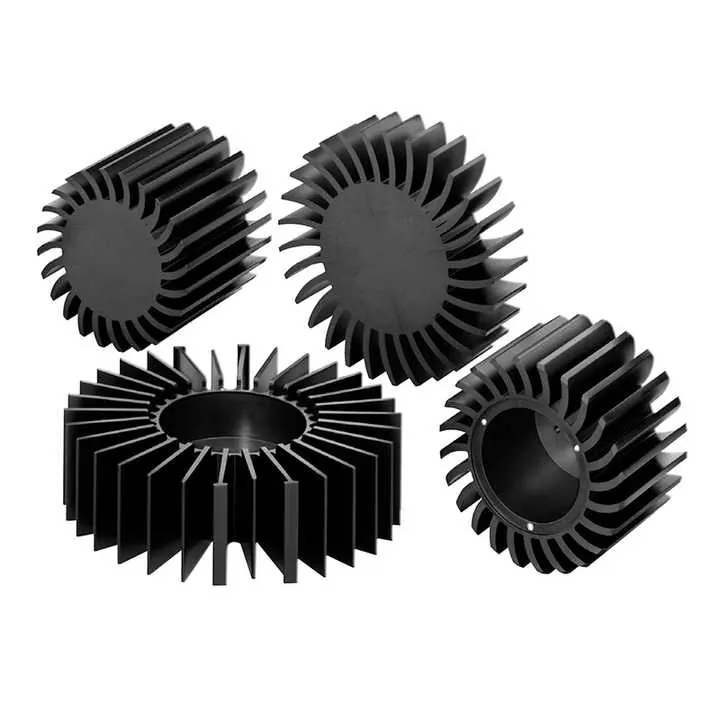

This method is ideal for producing symmetrical components such as rods, bushings, and shafts. Each turn is consistent, allowing for high repeatability in mass production.

Why is turning essential in metal machining?

Machining flat surfaces is simple. But round or cylindrical parts require more control and accuracy, which manual tools often lack.

Turning is essential because it enables precise shaping of round metal parts that are crucial in automotive, aerospace, and mechanical components.

Turning plays a major role in almost every industry that uses rotating or sliding parts. Most mechanical systems depend on round pieces that must fit tightly and move smoothly. Inconsistent roundness can lead to vibration, poor contact, or even failure in machines.

Key benefits of CNC turning in industry

- High precision: Tolerances can be as tight as ±0.01 mm.

- Repeatability: Produces thousands of identical parts with minimal deviation.

- Flexibility: Can work on small or large diameter parts.

- Speed: Automated control reduces cycle time significantly.

Use cases

| Industry | CNC Turning Application |

|---|---|

| Automotive | Shafts, pistons, gears, bearing housings |

| Aerospace | Jet engine parts, bushings, couplings |

| Medical | Surgical tools, implants, orthopedic components |

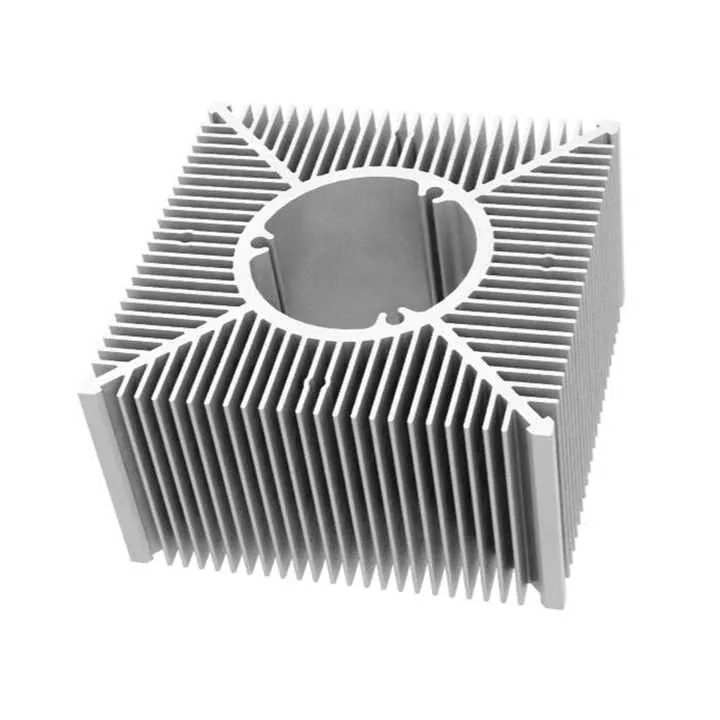

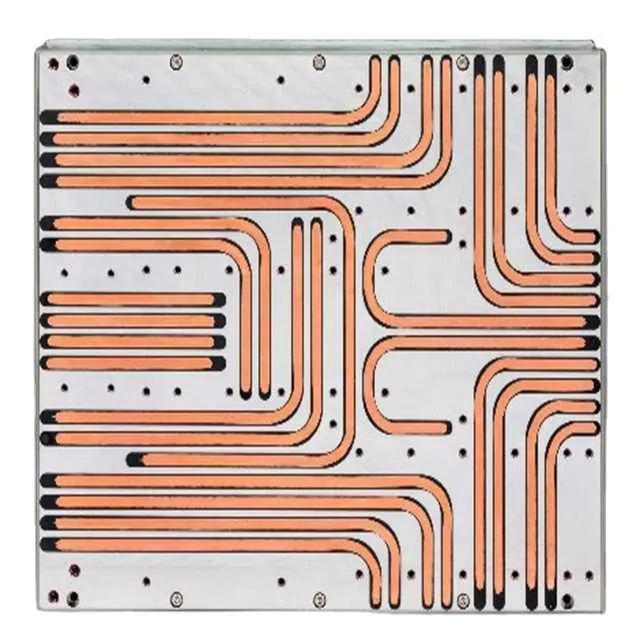

| Electronics | Connectors, casings, heat sinks |

Turning is also vital in producing threads, tapers, and internal bores. Unlike milling, which is ideal for flat and angular cuts, turning is optimized for radial precision and concentricity. This makes it indispensable for any rotating mechanical system.

Which materials are suitable for CNC turning?

Some materials are too soft, too hard, or behave unpredictably during cutting. Choosing the wrong material wastes time and damages tools.

CNC turning works well with metals like aluminum, steel, brass, and also certain plastics, depending on their hardness and melting point.

The machinability of a material affects how easy it is to cut, the speed of machining, and the finish quality. For turning, the key is to choose a material that offers a balance of strength, stability, and ease of cutting.

Most common CNC turning materials

1. Aluminum (6061, 7075)

- Lightweight and corrosion-resistant

- Good for high-speed cutting

- Ideal for aerospace and consumer electronics

2. Steel (mild, stainless)

- Strong and durable

- Needs proper cooling to avoid overheating

- Used in automotive, tooling, and construction

3. Brass

- Easy to cut, low friction

- Perfect for precision parts and decorative components

4. Titanium

- High strength-to-weight ratio

- More difficult to machine due to heat resistance

- Common in medical and aerospace sectors

5. Plastics (POM, Nylon, PTFE)

- Lightweight and chemically resistant

- Need sharp tools to avoid melting

- Often used for fittings, bushings, and insulators

Each material requires specific tooling, spindle speeds, and feed rates. For example, aluminum can be turned at high speeds with carbide tools, while titanium demands slower cutting and coolant to prevent tool damage.

What parameters control turning precision?

Even with CNC automation, poor settings can result in bad finishes, tool wear, and dimensional errors.

Turning precision is controlled by tool selection, cutting speed, feed rate, depth of cut, and machine rigidity.

Achieving precision starts before the tool touches the material. Parameters must be optimized based on part design, material, and desired finish.

Major factors influencing precision

1. Cutting Speed

- Measured in surface meters per minute (SFM)

- Too fast = overheating; too slow = poor finish

2. Feed Rate

- Affects surface finish and tool life

- High feed = faster but rougher cut; low feed = slower but smoother

3. Depth of Cut

- Determines how much material is removed per pass

- Deep cuts save time but strain the tool

4. Tool Geometry

- Sharpness, coating, and angle affect accuracy

- Right insert shape matches part geometry

5. Coolant Flow

- Reduces heat and removes chips

- Critical for high-speed or tough material turning

Example parameter settings for aluminum

| Parameter | Typical Range |

|---|---|

| Cutting speed | 200–500 m/min |

| Feed rate | 0.1–0.3 mm/rev |

| Depth of cut | 0.5–3 mm |

| Tool material | Carbide inserts |

Even small mistakes in setup—like a loose chuck or incorrect tool offset—can ruin a part. That’s why precision turning combines automation with careful planning and regular calibration.

Conclusion

CNC turning is a powerful method for creating round parts with high precision. It combines speed, accuracy, and versatility, making it essential in modern manufacturing. When materials, machines, and parameters align correctly, the results are consistent and reliable.