Polycarbonate (PC) is one of the most versatile thermoplastics used in a variety of industries. But how does CNC machining work with polycarbonate? In this article, we'll explore what polycarbonate CNC machining is, its advantages, and how to use it effectively in manufacturing.

Polycarbonate CNC machining is a process where CNC machines are used to precisely cut, shape, and mill polycarbonate plastic. This is typically done to create intricate parts with high accuracy and excellent finish quality. The ability to control such fine details makes it an essential process in industries like automotive, electronics, and manufacturing of optical parts.

In this post, we will take a deep dive into the advantages of polycarbonate CNC machining, how to do it effectively, and explore new trends that are shaping the future of this material's machining.

What are the advantages of Polycarbonate CNC Machining?

Polycarbonate is a unique material known for its excellent combination of physical properties. Let’s examine its advantages in CNC machining applications.

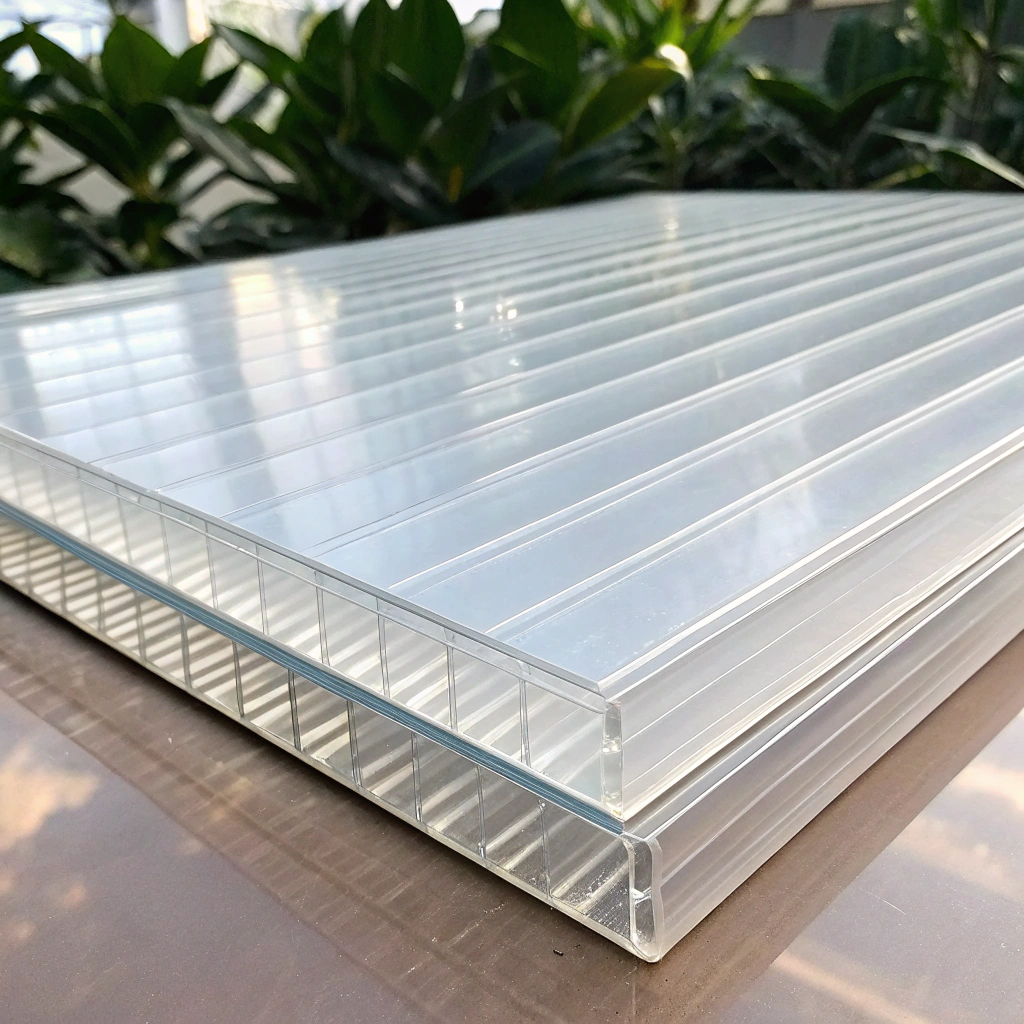

Polycarbonate is valued for its toughness and versatility. It offers exceptional impact resistance while still being lightweight. This makes it perfect for parts that require both durability and ease of handling. Polycarbonate is also highly transparent, allowing it to be used for applications that require optical clarity. Additionally, it has good thermal resistance and can handle moderate heat without deforming. These properties make polycarbonate an ideal candidate for CNC machining in industries that demand precision and durability.

Impact Resistance

Polycarbonate is incredibly strong and can withstand significant impacts, making it ideal for parts that need to endure tough conditions. This material is often used in safety equipment, automotive components, and machine covers, where toughness is essential.

Optical Clarity

The ability of polycarbonate to be machined into thin, clear parts without losing optical properties is an excellent advantage. This feature is particularly useful for lenses, lighting covers, and other applications where transparency is key.

Lightweight and Durable

Polycarbonate has a high strength-to-weight ratio. This makes it a go-to material for industries looking to reduce weight without compromising strength. Whether in automotive, aerospace, or even consumer electronics, polycarbonate helps reduce the overall weight of parts without sacrificing performance.

Heat Resistance

Polycarbonate can withstand higher temperatures than many other plastics. This makes it suitable for parts exposed to heat, such as automotive lighting, electrical housings, or medical devices.

How to Machine Polycarbonate Parts Effectively?

Polycarbonate is a delicate material that requires special care during machining. If you are looking to effectively machine polycarbonate, it's important to understand the right techniques and avoid common pitfalls.

To machine polycarbonate effectively, it’s critical to select the right tools and cutting parameters. Sharp, high-quality carbide tools are preferred, as they reduce the risk of heat buildup and material melting. Additionally, it’s important to set appropriate cutting speeds and feed rates. Too fast and the material could melt; too slow and you risk chipping.

Using proper cooling and lubrication is also key. Polycarbonate can soften under heat, so careful cooling is necessary to maintain the part's structural integrity and prevent surface defects.

Key Machining Tips:

- Use Sharp Tools: Opt for carbide tools that are sharp and maintain a proper edge. This will ensure that the material is cut cleanly without excessive heat generation.

- Cutting Speeds: Slow down the cutting speed to avoid overheating the material, which can lead to discoloration or warping.

- Cooling Methods: A small amount of air or a mist of coolant helps in dissipating the heat generated during machining, keeping the polycarbonate parts intact.

Tool Selection for Polycarbonate CNC Machining

| Tool Type | Material | Advantages |

|---|---|---|

| Carbide Tools | Polycarbonate | High durability, sharpness retention |

| High-Speed Steel | Polycarbonate | Cost-effective, suitable for low volumes |

Polycarbonate is prone to thermal damage, so having a controlled environment and a cooling system is important for maintaining optimal results.

What are the New Trends in Polycarbonate CNC Machining?

The world of CNC machining is rapidly evolving, and polycarbonate machining is no exception. As technology advances, new trends are emerging that are changing the way we work with polycarbonate.

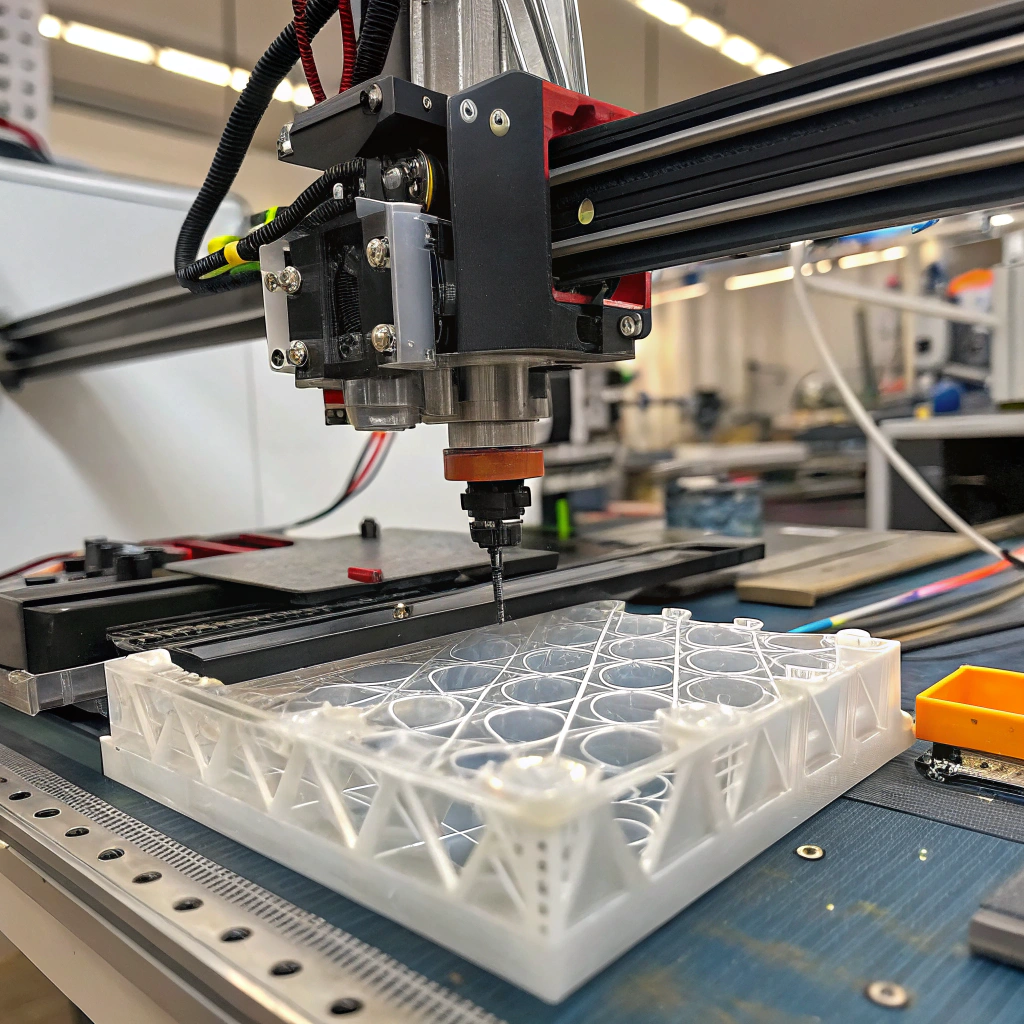

One of the most exciting trends is the integration of hybrid manufacturing technologies. This combines CNC machining with additive manufacturing, allowing for faster prototyping and more complex parts to be created. The ability to mix subtractive and additive techniques helps meet customer demands for intricate designs at lower costs.

Additionally, more CNC machines are being equipped with smart technologies, allowing real-time monitoring, predictive maintenance, and automatic adjustments to the cutting process. This leads to better efficiency and less downtime in production.

Hybrid Manufacturing

Hybrid manufacturing involves combining CNC machining with 3D printing. This hybrid method allows manufacturers to create complex parts more quickly. For example, the framework of a polycarbonate part could be 3D printed, while the detailed features are CNC machined.

Smart Machining Technologies

New advancements in IoT (Internet of Things) and AI (Artificial Intelligence) are making CNC machines smarter. These machines can now self-diagnose issues, predict tool wear, and adjust settings on the fly to optimize the machining process.

Robotics and Automation

Robotic systems are increasingly being used in the CNC machining process. Robots can handle tasks like loading and unloading parts, reducing human error, and increasing production rates. This is especially beneficial when machining polycarbonate parts, which require precise handling.

| Trend | Benefits |

|---|---|

| Hybrid Manufacturing | Faster prototyping, cost savings |

| Smart Machines | Increased efficiency, less downtime |

| Robotics in Machining | Improved accuracy, faster production |

Conclusion

Polycarbonate CNC machining is a valuable process in modern manufacturing, offering benefits like impact resistance, optical clarity, and strength. By staying up-to-date with the latest trends and applying best practices, manufacturers can effectively machine polycarbonate parts for a wide range of industries.