Many manufacturers struggle with inconsistent part quality and missed tolerances. Precision CNC machining solves this by delivering exact specifications for demanding industries.

Precision CNC machining is a high-accuracy manufacturing process that uses computer-controlled tools to produce components with tight tolerances, typically within ±0.005 mm.

Modern production demands more than just speed and efficiency. Precision machining is about achieving the highest level of accuracy while maintaining consistency across thousands of parts.

What defines precision CNC machining?

Manufacturers often face costly rework due to minor inaccuracies. That’s where precision CNC machining becomes essential—it eliminates errors before they happen.

Precision CNC machining is defined by its ability to produce parts that meet exact dimensional and geometric requirements, often within microns.

To understand what defines precision CNC machining, we must look at several key features:

Tolerances

Tolerances are the allowable deviation in a dimension. In precision CNC machining, tolerances usually fall within:

| Tolerance Type | Typical Range |

|---|---|

| Standard CNC Tolerances | ±0.1 mm |

| Precision Tolerances | ±0.01 mm to ±0.005 mm |

| Ultra-Precision | < ±0.002 mm |

Tighter tolerances require more stable machines, sharper tools, and better calibration.

Surface Finish

Surface finish also plays a role. Precision parts often require finishes below Ra 0.8 μm to reduce friction or meet aesthetic requirements.

Toolpath Control

CNC systems use G-code to control the machine’s movements. The more refined the toolpath, the better the result. Precision machining minimizes vibrations, tool deflection, and backlash.

Machine Calibration

Proper calibration ensures the spindle and axes move exactly as programmed. Even a minor misalignment can throw off precision by microns.

Precision CNC machining is not a general-purpose process. It involves choosing the right material, tooling, feeds and speeds, and software—all aligned for one goal: accuracy.

Why is precision important in CNC machining?

Low-precision parts may pass initial inspection but fail in real-world applications. When parts don’t fit or wear out early, the cost multiplies fast.

Precision in CNC machining ensures parts function correctly, fit seamlessly, and last longer, especially in applications where safety and reliability are critical.

When you’re making thousands of the same part, consistency matters. A small dimensional error on one part becomes a big problem when scaled. Here’s why precision is not just beneficial, but necessary:

Assembly Fit

Parts must fit with each other. Misalignment by even 0.1 mm can lead to:

- Poor sealing

- Assembly issues

- Vibration and noise

- Increased wear

Product Performance

Precision affects how a part behaves under stress, pressure, or motion. For example, in aerospace, a poorly machined turbine blade could cause vibration, reduced thrust, or engine failure.

Cost of Errors

The cost of a defective part goes beyond materials:

- Labor to fix or replace

- Delays in production

- Customer dissatisfaction

- Damaged reputation

Safety Concerns

In industries like medical and automotive, a slight error can cause accidents. That’s why standards are strict, and why precision CNC machining is essential.

Accuracy also supports automation. When each part is made to spec, downstream robots and systems can work without adjustment.

Which industries require precision CNC machining?

Some sectors simply can't afford guesswork. They rely on absolute precision to keep people safe and operations running smoothly.

Precision CNC machining is essential in industries such as aerospace, medical devices, automotive, electronics, defense, and high-end consumer products.

Each of these industries has its own tolerance expectations, material needs, and certification standards. Let’s look at the specifics.

Aerospace

Parts in aircraft must endure extreme heat, pressure, and stress. Common aerospace components include:

- Turbine blades

- Structural brackets

- Landing gear parts

- Engine housings

Each component must be light but strong, often made from titanium or aluminum alloys. Even a 0.01 mm error can compromise airworthiness.

Medical

In this field, biocompatibility and precision go hand in hand. Examples include:

- Orthopedic implants

- Surgical tools

- Dental components

- Diagnostic devices

Medical parts often require materials like stainless steel, titanium, and PEEK, all machined to tight tolerances and ultra-smooth finishes.

Automotive

Modern vehicles are more electronic and sensor-dependent. CNC precision affects:

- Engine blocks

- Transmission gears

- Brake system components

- EV battery housings

Improperly machined parts can cause noise, fuel inefficiency, or system failure.

Electronics

In phones, laptops, and circuit boards, precision is key. CNC machining helps create:

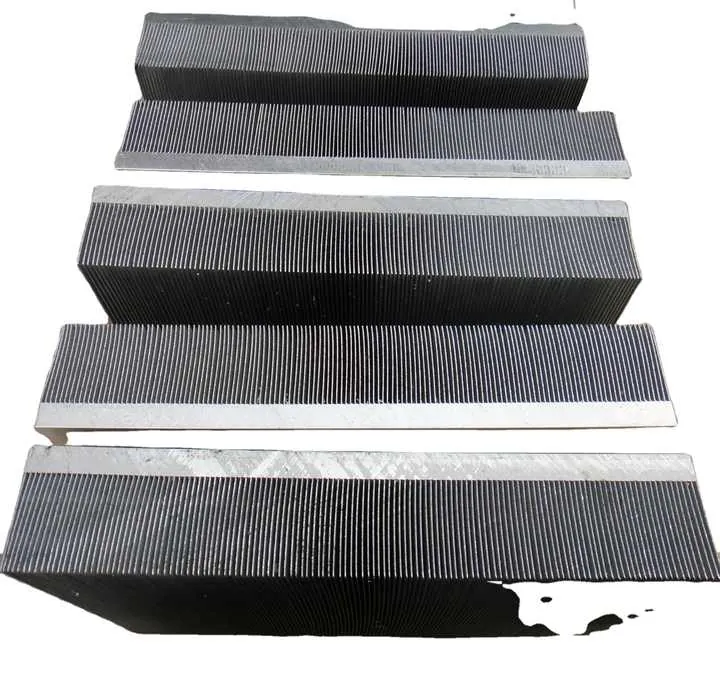

- Heat sinks

- Casings

- Connector components

- Precision frames

These parts must be dimensionally accurate and visually perfect, often made from aluminum or magnesium.

Defense and Security

Weapons systems, radar components, and communication systems depend on parts that must perform flawlessly, no matter the environment.

Here’s a summary of some precision-critical industries:

| Industry | Common CNC Parts | Tolerance Requirements |

|---|---|---|

| Aerospace | Turbine blades, brackets | ±0.005 mm or tighter |

| Medical | Implants, tools, housings | ±0.01 mm |

| Automotive | Gears, brake parts, housings | ±0.02 mm |

| Electronics | Frames, heat sinks, connectors | ±0.01 mm |

| Defense | Mounts, receivers, enclosures | ±0.005 mm |

Precision is not a luxury in these fields—it’s the standard.

What factors influence the precision of CNC machines?

Precision doesn’t happen by accident. It’s the result of careful planning, right machines, and controlled environments.

The main factors affecting CNC machine precision include machine rigidity, thermal stability, tool condition, material properties, and operator skill.

Let’s break down the key elements that impact CNC precision:

1. Machine Rigidity

A CNC machine must be rigid to resist cutting forces. If the machine flexes during operation, even slightly, it introduces errors.

- Heavier machines are more stable.

- Cast iron bases absorb vibration better.

- High-end CNCs have reinforced frames.

2. Thermal Expansion

Metal expands with heat. This affects both the part and the machine itself.

- Spindle temperature can change tool length.

- Cutting heat can distort the workpiece.

- Shops must monitor ambient temperature and allow warm-up time.

3. Tool Wear

As cutting tools wear out, they lose sharpness. This changes cutting pressure, increases heat, and reduces accuracy.

- Regular tool inspection is crucial.

- High-speed steel wears faster than carbide or ceramic tools.

4. Material Characteristics

Some materials are easier to machine precisely than others. For example:

| Material | Machinability | Common Use |

|---|---|---|

| Aluminum 6061 | Excellent | General components |

| Stainless Steel 304 | Moderate | Medical and food industry |

| Titanium | Difficult | Aerospace and medical |

| Brass | Good | Electronics and fittings |

Different materials also react differently to heat, force, and vibration.

5. Software and Programming

CNC programs must be optimized for:

- Toolpath efficiency

- Entry and exit strategies

- Chip evacuation

- Minimal tool engagement

Advanced software like CAM tools helps simulate and detect potential accuracy issues before production.

6. Operator Expertise

Even with automation, human skill matters:

- Proper setup ensures parts are clamped and aligned.

- Regular calibration maintains accuracy.

- Visual inspection catches issues machines might miss.

Precision machining is a combination of good machines, trained operators, and careful process control.

Conclusion

Precision CNC machining is more than a buzzword—it's a foundation for quality manufacturing across critical industries. It ensures parts are accurate, reliable, and safe to use. When tolerances matter, precision isn’t optional—it’s the standard.