When you need to cut narrow, straight paths into metal, plastic, or other solid materials, slot milling is the go-to process. But what makes it essential in precision manufacturing?

Slot milling is a machining technique used to cut narrow, straight grooves or slots into solid materials using a rotating cutting tool. It is widely used in manufacturing for parts that require tight tolerances and specific shapes.

Whether you're working in aerospace, automotive, or general fabrication, knowing how slot milling works—and how to do it right—can save you time, money, and rework.

What is slot milling?

Slot milling is used to create straight, narrow grooves in a material surface. Why is this needed so often? Because these grooves serve as key features in mechanical assemblies, helping parts align, fit, or slide precisely.

Slot milling is a process where a milling cutter removes material from a solid workpiece to create a slot, usually with defined width and depth. This slot can be open-ended or closed.

The main tool used is called a slot mill or slot cutter. It rotates at high speed and moves along the surface of the workpiece. This action removes material and forms the desired groove or channel.

Types of slot milling:

| Type | Description |

|---|---|

| Full Slot Milling | The cutter removes material equal to its full diameter. |

| Partial Slot Milling | The cutter removes part of its diameter, often used in step operations. |

| Open Slot Milling | Slots that go all the way through the workpiece ends. |

| Closed Slot Milling | Slots that stop before the end of the material. |

Materials used:

Slot milling can be applied to:

- Aluminum (such as 6063 or 6061 alloys)

- Steel

- Titanium

- Plastics

- Composites

Tools involved:

- End mills (2-flute, 3-flute, or 4-flute depending on the material)

- Carbide slot cutters

- High-speed steel (HSS) tools

Slot milling may look simple, but doing it with accuracy takes planning and the right setup.

What are the advantages of slot milling?

Many industries rely on slot milling every day. But why choose it over other cutting methods?

Slot milling provides accurate, repeatable cuts with smooth finishes. It supports complex geometries and high-volume production, while reducing material waste and tool wear.

Slot milling is more than just a groove-making process. It provides many benefits in both small-batch and mass production.

Benefits of slot milling:

1. Precision

Slot milling allows for very precise width and depth control. This makes it ideal for parts where tight tolerances matter. The toolpath can be adjusted to hundredths of a millimeter.

2. Flexibility

It works with many materials and tool shapes. This means you can create a wide variety of slots for different mechanical functions.

3. Surface finish

Slot milling produces a smoother surface than sawing or laser cutting. This reduces the need for secondary finishing processes.

4. Cost-efficiency

It removes only the material needed, minimizing waste. Carbide tools also last longer, reducing tooling costs.

5. Automation-friendly

Slot milling operations can be programmed into CNC machines. This ensures consistency and efficiency in large runs.

6. Structural performance

Slots often increase the strength-to-weight ratio in components. In industries like aerospace, this is a big win.

Here’s a quick comparison:

| Feature | Slot Milling | Laser Cutting | Sawing |

|---|---|---|---|

| Precision | High | Moderate | Low |

| Surface Finish | Smooth | Varies | Rough |

| Material Flexibility | High | Medium | Low |

| Cost (per part) | Medium | High | Low |

| Tool Life | Long | No tool | Medium |

How to perform slot milling operations?

Cutting a perfect slot involves more than picking a cutter and turning on the machine. It starts with planning, setup, and step-by-step execution.

To perform slot milling, you must choose the right cutter, set proper speeds and feeds, align your workpiece, and use step-over passes to avoid tool deflection or breakage.

Let me walk you through the main steps in detail.

Step 1: Choose the right tool

You need to match the slot size and material to the tool. For example, if I’m cutting aluminum, I’ll often use a 2-flute carbide end mill. If the slot is deep, I’ll pick a long-reach cutter.

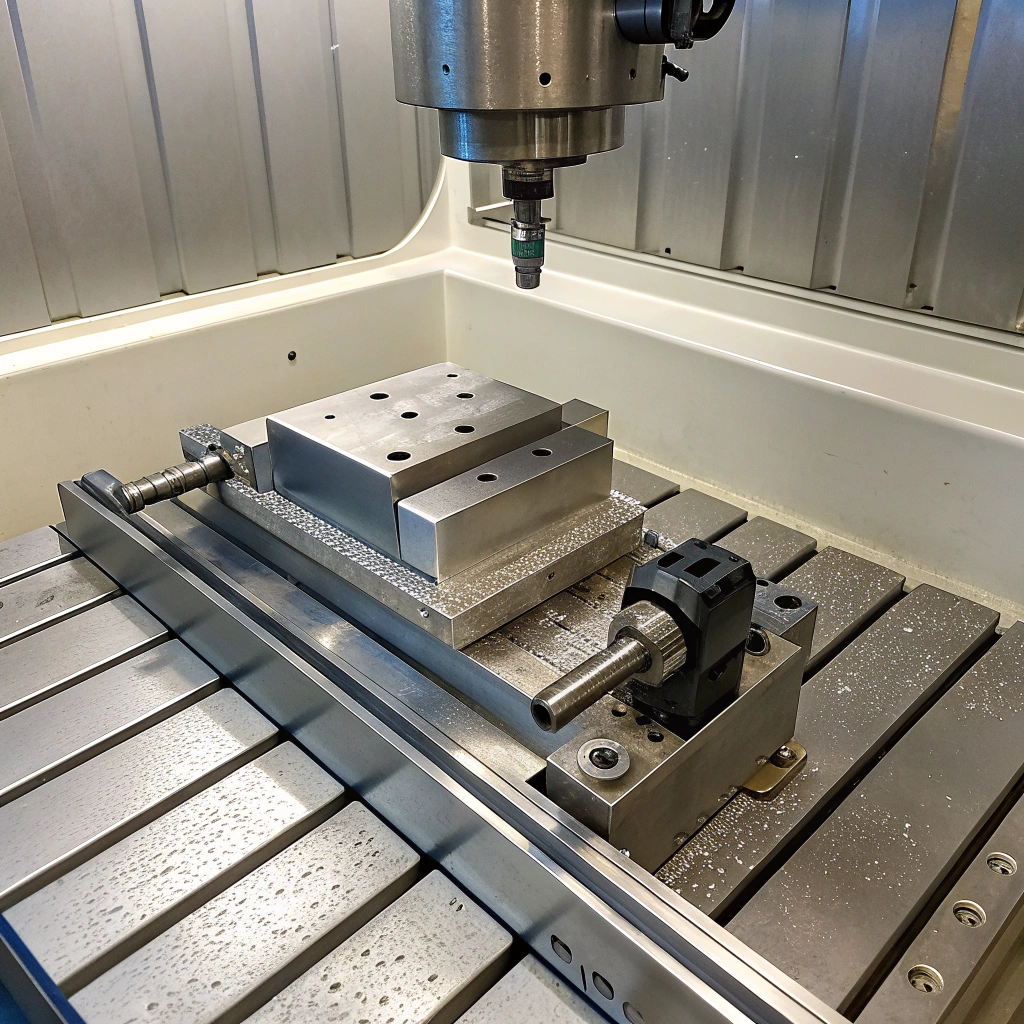

Step 2: Fix the workpiece

Clamping is crucial. Loose setups cause chatter and inaccuracy. Use a vise or fixture to secure the part on the machine bed.

Step 3: Set machine parameters

Set your RPM and feed rate based on:

- Material type

- Tool diameter

- Depth of cut

For example:

| Material | RPM | Feed Rate (mm/min) |

|---|---|---|

| Aluminum 6061 | 12,000 | 1200 |

| Mild Steel | 8000 | 900 |

| Plastic (ABS) | 6000 | 1500 |

Step 4: Use step passes

Instead of cutting the full depth in one pass, I take it in layers. This reduces heat, tool wear, and breakage.

Step 5: Clean and inspect

After milling, remove chips and inspect the slot with a caliper or profile gauge.

Pro Tips:

- Use coolant for metals to avoid overheating.

- Watch for tool wear signs like vibration or poor finish.

- Avoid over-engagement. If the slot is wide, make two passes with step-over.

With experience, slot milling becomes a fast and reliable operation in any shop.

What are the innovations in slot milling tools?

Toolmakers are always improving what slot cutters can do. New tech brings faster speeds, longer tool life, and better finishes.

Innovations in slot milling include multi-flute carbide tools, internal coolant channels, AI-based tool pathing, and advanced coatings like TiAlN for extreme durability.

Let’s look at the latest developments that have changed how I and many others approach slot milling:

1. Advanced tool coatings

New coatings like Titanium Aluminum Nitride (TiAlN) help tools resist heat and wear. This allows deeper cuts at higher speeds. Tools last longer and need fewer replacements.

2. Multi-flute designs

Modern end mills now come with 5 or more flutes. These increase the material removal rate while keeping the finish smooth. Especially useful in hardened steels and composites.

3. Coolant-through tools

Some cutters now allow coolant to flow through their center. This cools the cutting edge directly and flushes away chips. Great for deep slots and hard metals.

4. Vibration-reduction geometries

New fluting patterns are designed to reduce chatter. These allow higher speeds without sacrificing quality.

5. AI-powered CNC strategies

Some modern CAM (computer-aided manufacturing) software includes AI-driven toolpath optimization. These systems adjust paths in real-time based on material load, reducing cycle time and tool wear.

6. Modular tooling

Toolmakers offer modular heads for different slot widths. You can swap out the cutting section without changing the whole tool body. Saves cost and speeds up setup.

Why this matters:

With these improvements, I’ve seen up to 40% faster cycle times and 2–3x longer tool life. That’s not small. It means less downtime, more output, and happier clients.

If you’re running a machine shop, upgrading your slot milling tools is a smart investment. The gains go straight to your bottom line.

Conclusion

Slot milling is one of the most useful and precise methods for shaping grooves in solid materials. With the right tools, setup, and strategy, it can boost quality and efficiency across many industries.