Looking for a CNC plasma cutter that really works? Many machines look good on paper — but often fall short when cutting real metal.

The best CNC plasma cutter depends on your use: one that matches your materials, budget, and precision needs tends to perform best.

If you keep reading, I will walk you through how to choose the right one, what to watch out for, and which machines stand out now.

How do you choose the best CNC plasma cutter?

Want a cutter that truly fits your shop? First you must match the machine to your needs — size, material, power, and purpose all matter.

You pick the best CNC plasma cutter by matching its specs (cutting area, power, control, durability) with the types of jobs you will do.

CNC plasma cutters vary a lot. Some are for small jobs or home shops; others are for industrial or heavy-duty use.

When choosing, consider:

- Table size / working area — Make sure the cutter bed is large enough for your metal sheets or parts. Small tables suit small parts; large tables handle big sheets.

- Power and cutting capacity — The machine must have enough amperage and torch power to cut the thickness and type of metal you plan to work with.

- CNC and automation features — A good CNC controller, torch height control (THC), software compatibility, and automation help ensure precision and efficiency.

- Durability and build quality — A solid frame, quality motion control system, reliable torch, and robust components reduce downtime and increase lifespan.

- Intended use (hobby vs. industrial) — For occasional light work, compact or entry-level machines are enough. For production or frequent heavy cuts, you need industrial-grade machines.

If you match your needs carefully, you avoid spending too much on overkill equipment or getting stuck with a weak machine.

What features should you look for in a CNC plasma cutter?

Choosing a CNC plasma cutter means looking beyond marketing — some technical features make a big difference in cut quality, safety, and long-term reliability.

Critical features include automatic torch height control, CNC controller + software compatibility, power/ amperage to match material thickness, and a sturdy working bed.

Here are key attributes in more detail:

🔧 Essential Features to Evaluate

| Feature | Why It Matters |

|---|---|

| Torch Height Control (THC) | Keeps the torch at correct distance from metal. This ensures clean cuts and protects nozzle from crashing. |

| CNC Controller and Software Compatibility | Lets you run accurate, repeatable cuts from CAD designs. The software must support your design format (e.g. DXF) and control the motion precisely. |

| Cutting Capacity (Power, Amperage, Material Thickness) | The amperage and torch strength determine how thick a metal sheet you can cut reliably. Machine’s spec must match or exceed your typical material needs. |

| Work Area / Table Size | Larger sheets or bigger parts need a larger bed. Too small a table limits what you can cut. |

| Frame and Build Quality | Heavy-duty frame, accurate motion system (rails, stepper/servo motors), stable base — these affect precision, repeatability, and durability under long-term use. |

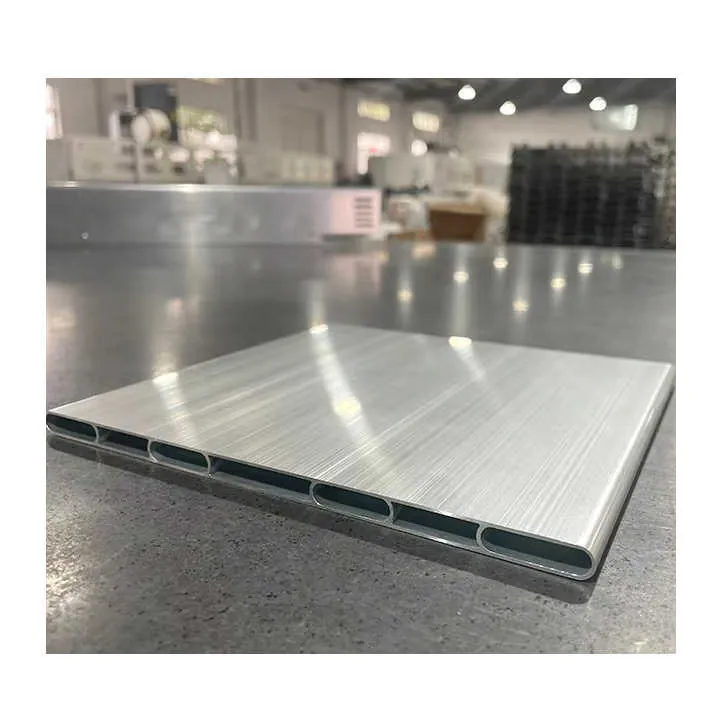

| Versatility (Material Types, Plate Sizes, Add‑ons such as Bevel, Drill, etc.) | A versatile cutter allows different metals (steel, aluminum, alloys), different thicknesses, and additional operations (beveling, drilling) if needed. |

| Maintenance and Consumables Availability | Easy-to-get nozzles, torches, consumables; stable maintenance schedule; reliable parts supply — critical for long-term use. |

If a CNC plasma cutter has these features — strong power, good THC, precise controller, big enough table, and solid build — it will likely serve you well, whether for occasional use or heavy-duty projects.

Which brands are known for producing high-quality CNC plasma cutters?

Some brands and machines have built reputations over time for reliability, precision, and good support. Choosing a known brand can save headaches with part replacement and support.

Brands and models often praised include Langmuir Systems, StyleCNC, Eastwood, and heavier industrial tables from specialists — these combine decent build quality with good value.

Here are several well‑regarded options:

👇 Recommended CNC plasma cutters

| Brand & Model | Price | Size | Ideal For |

|---|---|---|---|

| Langmuir CrossFire | $1,495 | Compact | Entry-level hobby |

| Langmuir CrossFire XR | $6,495 | 4x8 | Mid-range shops |

| StyleCNC 4x8 Table | $4,680 | 4x8 | Budget full sheets |

| Eastwood Versa-Cut 4x4 | $4,499 | 4x4 | Mid-range 4x4 |

| STV CNC Sparx 4800 | $6,799 | 4x8 | Industrial cutting |

| Everlast 62i CNC Kit | $1,400 | Kit | Budget CNC starter |

| STV CNC Sparx Pro 5x10 | $10,999 | 5x10 | Heavy production |

| Eastwood Elite 4x4 | $7,999 | 4x4 | Pro workshop |

These machines vary in price and use-case. Hobbyists might go for Langmuir CrossFire. For heavier work, STV’s 5x10 table or Eastwood’s Elite line are better choices.

What industries rely on the best CNC plasma cutters?

CNC plasma cutters are not niche tools. Many industries depend on them — especially those working with metal parts, large structures, or repeated cutting jobs.

Industries such as manufacturing, metal fabrication, construction, automotive repair and customization, and industrial parts production rely heavily on high‑quality CNC plasma cutters.

🏭 Manufacturing & Metal Fabrication

Manufacturers that produce metal parts — frames, brackets, machine parts, panels — often use CNC plasma cutters. The CNC control ensures repeatability and precision for every part. Plasma cutting is faster than manual cutting and reduces waste.

🏗️ Construction & Structural Steel Work

Construction firms working with steel beams, plates, and metal components use CNC plasma cutters to cut parts for structural frames, beams, and metal panels. Precision cutting helps ensure accurate fit and welding.

🚗 Automotive & Custom Metal Parts

Automotive repair or custom fabrication shops use CNC plasma cutters for cutting chassis parts, exhaust parts, custom brackets, metal art, and body panels. The versatility covers small parts to large plate sections.

🛠️ Small Metal Workshops / Prototyping Shops

Small workshops and prototyping shops benefit from CNC plasma cutters for custom jobs, custom parts, prototypes, one‑off pieces. Machines like desktop or 4×4 tables suit this well.

🏭 Industrial Production for Heavy Equipment

For heavy equipment — machinery, large metal frames, structural components — industrial‑grade CNC plasma tables handle thick metal sheets and large parts. These machines bring power, precision and endurance for long production runs.

Because of their versatility and speed, CNC plasma cutters serve both custom small‑batch jobs and large‑scale industrial production.

Conclusion

The “best” CNC plasma cutter is not universal — it depends on what you need. A good machine matches your material types, thickness, work size, precision needs, and budget.

When you choose a cutter that fits your tasks — from small metal pieces to large structural sheets — you get reliable, efficient, high-quality cuts with less waste and fewer problems.