Small CNC machines feel like magic tools for makers. They bring real precision in small packages.

Many compact CNC tools offer great cutting, carving, and shaping power in small spaces. They often give enough quality for hobby, small business, or prototype work.

If you are curious about small CNC, you will want to learn how they differ, why they matter, who should pick them, and where to buy. This guide helps you find the best match.

How do small CNC models differ?

Small CNC models can vary more than you expect. Some are tiny desktop units for hobby projects. Others are more powerful but still compact.

Differences come from size, power, speed, and work area.

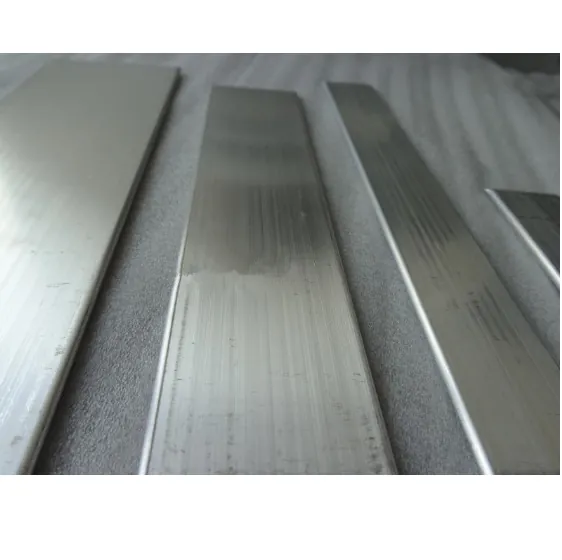

When I look at small CNC machines, I see big variation. Some use simple tools and small motors. Others use stronger motors and metal parts. The work area may be small — maybe 150 × 150 mm — or larger — maybe 400 × 300 mm. Some machines are built for wood or plastic. Others can cut soft metals like aluminum.

Key factors that differ

| Feature | What it means | Impact on use |

|---|---|---|

| Work area size | Physical space that the tool can reach (e.g. 150×150 mm vs 400×300 mm) | Limits how big a piece you can cut or carve |

| Spindle power / motor strength | How strong cutting or milling force is | Stronger motors cut harder materials; weak motors suit soft wood/plastic |

| Build quality / rigidity | Frame materials, motor mount quality, stability | Better stability gives more accurate cuts; weak frame may wobble |

| Supported materials | Wood, plastic, PCB, soft metals, hard metals | Determines what projects you can do |

| Software / control system | How easy programming and control are | Easier software helps beginners; complex ones suit advanced users |

Because of these differences, two machines that look “small CNC” may work very differently. A hobby CNC may carve wood or plastic for art. A stronger compact CNC may cut aluminum parts for a small mechanical project.

When you pick a small CNC, ask: What material do I plan to process? What size parts will I make? How precise do I need to be? What workspace do I have? These questions help you avoid disappointment.

Also watch spindle speed and torque. For plastics or wood, high speed and low torque might work. For metals, you want lower speed but high torque. Some small CNC models let you change these settings. Others don’t.

Another difference lies in the software and control. Some come with beginner‑friendly, graphical control panels. Some require G‑code knowledge. For beginners or small shops, easier software reduces learning time. For experienced users, flexible software supports complex jobs.

Finally, build quality matters. A desktop CNC made mostly from plastic or thin metal may vibrate or lose precision over time. A sturdier frame — steel or heavy alloy — improves accuracy and durability.

In short: “small CNC” is not one uniform class. It spans a range from hobby engravers to semi-professional fabrication machines. The differences in work area, power, build, software, and supported materials determine what each machine is good for.

Why choose compact CNC machines?

Compact CNC machines save space. They cost less. They allow work in small workshops.

Small CNC brings good value for light work, prototypes, and small‑batch projects.

Compact CNC machines work well when you do small projects. They need less room. They cost less money than full-size machines. They still give enough precision and flexibility.

Advantages of compact CNC machines

- Space saving — You can put many small CNC on a desk. They fit in small shops or home garages.

- Lower cost — Compared to large CNC mills, compact ones are cheaper. This helps businesses or hobbyists with small budgets.

- Suitable for prototypes — When you need one-off parts or small production, a compact CNC works well.

- Lower maintenance — Fewer parts, simpler mechanics, easier to keep in shape.

- Faster setup — Smaller size means less clutter, easier to mount materials, less cleanup.

- Flexibility — One machine can do wood carvings, plastic, maybe light metal machining if built properly.

For small manufacturers, compact CNC can be a cost‑efficient choice. For designers, they allow quick turning of ideas into real parts. For craftspeople, they offer a mix of precision and convenience.

I once saw a small workshop that built custom aluminum cases. They used a compact CNC to cut parts. The small machine did the job in hours instead of days. The full‑size factory machines would be overkill. The compact CNC gave just the right fit.

Compact CNC also helps when you want trial runs. Before ordering many large parts from a big factory, you can test on a small machine. This reduces waste and lowers cost. The small CNC helps catch design flaws early.

One more advantage is learning curve. For beginners in CNC machining, small machines are friendlier. They require less power, simpler mounting, and easier cleanup. Users can experiment without big risk. They learn how to plan, mill, and finish parts safely.

Compact CNC machines also use less electricity and consume fewer resources. For small businesses or shops in areas with limited power, this is helpful. It reduces cost and environmental impact.

Because of all these benefits, many users pick compact CNC when they need flexibility, low cost, small footprint, and fast setup.

Which users need desktop CNC?

Desktop CNC suits many kinds of users. Hobbyists, small shops, designers, DIY‑builders.

If work is small scale, custom, or one‑off, desktop CNC often is the best fit.

People who build prototypes, small parts, art, models, or custom items often choose desktop CNC. They do not need a full factory CNC. They want lower cost and smaller size.

Who benefits from desktop CNC

Hobbyists and artists

They make wood carvings, engraving, plastic models, art pieces, jewelry molds. They need precision but not heavy metal cutting. Desktop CNC offers enough power. It fits in a home workshop and costs less. They can test designs fast.

Small makers and custom‑part producers

Small businesses that build custom enclosures, fixtures, or metal parts with small volume. They do not need big production. A desktop CNC gives flexibility. They can adjust design quickly. They save cost by avoiding big factory setups.

Engineers and designers doing prototypes

When new designs launch, they need physical prototypes. Desktop CNC helps make sample parts fast. It allows testing shape, fit, and function before ordering mass production. This reduces mistakes and saves cost.

Educational workshops and students

Schools or training centers teaching machining need safe, small, easy‑to‑control machines. Desktop CNC offers hands‑on learning at lower risk and cost. Students can learn basics without dealing with heavy machines.

DIY and home‑improvement hobbyists

People building small furniture, custom parts, decorations at home. They need tools to cut wood, plastic, or light metal. Desktop CNC gives them a tool that they can keep at home.

When desktop CNC is not enough

If user needs to cut large metal parts, or needs high volume production, desktop CNC may fail. It may lack power, work area, or durability. In such cases, a larger CNC machine is needed.

Desktop CNC works best when projects are small, precise, or custom. It suits anyone who values flexibility, low cost, and small workspace.

Where to buy small CNC units?

Many online stores, specialized machine sellers, and industrial suppliers offer small CNC machines.

Buy from trusted sellers with clear specs and good support.

Many sellers on the web or local distributors sell small CNC units. Choose ones with clear information on work area, motor power, materials, and support.

What to check before buying

| Check | Why it matters |

|---|---|

| Work area size | Ensures the machine fits your intended parts |

| Spindle/motor power and RPM | Determines materials you can process |

| Frame quality and build material | Affects precision and durability |

| Software included and support | Easy programming reduces learning pain |

| Spare parts availability | Helps maintenance and repairs |

| Seller reputation and reviews | Avoid scams or poor quality machines |

I recommend starting with widely known platforms and sellers who offer support. Buying locally sometimes helps, but online shops with spare‑part stock and good reviews may give better deals.

I once ordered a small CNC from an overseas seller. The specs looked good. After arrival I found that spare parts were hard to get. That slowed down my work. I now prioritize sellers who offer spare parts and support.

Some sellers also offer customization — different spindle types, work tables, or extra tooling. If you plan to process metal or different materials, ask about such options.

Prices vary a lot. Some desktop CNC start at a few hundred dollars. More capable small CNC with stronger motors and larger work areas cost more. For business use, it is often worth paying more for better build and power. For hobby or learning, entry‑level models may suffice.

If you plan to order in bulk or import for a workshop, check shipping, customs, and support policies. Large or heavy machines may add shipping cost. Make sure seller offers clear instructions and user manuals.

Conclusion

Small CNC machines offer flexible, low‑cost, space‑saving machining for hobbyists, small shops, and makers needing small or custom parts. The best machine depends on your material, part size, workspace, and budget. Choose with care.