Looking for a CNC machine, but worried about the price? You’re not alone. Many small businesses and hobbyists are searching for budget-friendly options.

The cheapest CNC machines are small, entry-level models designed for light-duty tasks. They are usually desktop-sized, use simple components, and start under $500.

But cheap doesn’t always mean bad. Some low-cost machines offer excellent value if matched with the right expectations.

What factors affect the cost of a CNC machine?

It’s easy to assume price is only about size or brand. But cost involves more than that.

The cost of a CNC machine depends on factors like size, build materials, type of cutting technology, axis count, software compatibility, and included features.

Let’s break it down further:

Main Factors That Influence CNC Machine Price:

| Factor | Impact on Cost |

|---|---|

| Size & Build Area | Larger machines cost more |

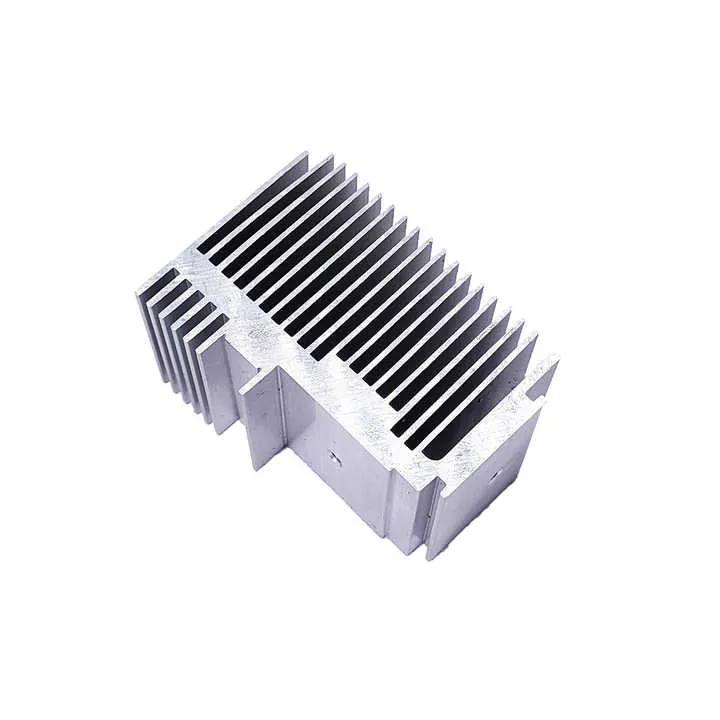

| Material Quality | Steel frames cost more than aluminum or plastic |

| Spindle Power | Higher wattage adds to the price |

| Axes Count | 5-axis machines are more expensive than 3-axis |

| Control System | Advanced controllers increase costs |

| Precision & Repeatability | Tighter tolerances require better components |

| Software Compatibility | Some include paid CAD/CAM software licenses |

| Brand & Support | Trusted brands charge more for warranty, service |

A small CNC router for hobby use might use a basic stepper motor system, while an industrial-grade model uses high-torque servo motors. That alone creates a large price difference.

The material of the machine frame is another cost driver. Plastic frames flex under pressure, while cast iron or steel adds strength—and cost.

Features like auto tool changers, dust collection ports, and touch screen interfaces all affect the final price. It’s not just the machine—it’s the package.

Why do some CNC machines cost less than others?

It’s not always about quality. Sometimes, lower cost reflects smart design or fewer features.

Some CNC machines cost less because they are built for lighter tasks, use simpler components, or are produced in bulk without brand markups.

There are several reasons why prices vary, even for machines that look similar.

Key Reasons for Price Differences:

- Usage Level: Hobbyist machines use low-power motors and lightweight frames.

- Production Volume: Mass-produced machines from China cost less due to economies of scale.

- Features Removed: Entry-level machines skip features like enclosures, sensors, or tool changers.

- Support & Warranty: Budget machines often lack after-sales support.

- Branding: Lesser-known brands charge less, while well-known brands include markup for reputation.

A real-world example: a hobby CNC machine for wood engraving might use a 300W spindle, cost under $400, and work for basic tasks. An industrial version might have a 3kW spindle, full enclosure, and cost $10,000 or more.

Also, budget CNCs often require DIY assembly. That saves manufacturing cost, but requires buyer skill. The machine may also lack certifications or durability expected in commercial environments.

Some cheap machines may not include software, while higher-end ones come with full CAD/CAM systems. That’s another hidden cost.

Cheap CNC machines fill an important gap—for learners, DIYers, and small shops that don’t need industrial-grade specs.

Which CNC machines are generally the most affordable?

Not all CNCs are priced the same. Some types are naturally cheaper due to their design and use case.

The most affordable CNC machines are usually desktop CNC routers, hobby laser engravers, and small CNC mills made for beginners.

These machines are designed with budget in mind. They cut soft materials like wood, plastic, foam, and thin aluminum sheets. They’re perfect for schools, makerspaces, and entry-level users.

Affordable CNC Machine Types and Their Features:

| CNC Type | Price Range | Ideal Use |

|---|---|---|

| Desktop CNC Router | $200–$1,500 | Wood signs, small parts, engraving |

| Mini CNC Mill | $300–$2,500 | Aluminum, PCB milling |

| Laser Engraver | $100–$1,200 | Wood, acrylic, leather |

| CNC Plasma Cutter | $500–$3,000 | Metal sheet cutting (basic models) |

| 3D Printer with CNC Add-on | $200–$600 | Multi-use, not industrial grade |

Examples include:

- 3018 Pro CNC – Very popular budget machine for engraving.

- Genmitsu 4030 – Larger build volume, still affordable.

- NEJE Laser Cutter – A beginner-friendly laser machine.

Most of these models come in kits. Users assemble them, load free software like GRBL, and start cutting. Advanced users can upgrade the spindle, frame, or add features later.

They work best on projects like PCB drilling, jewelry, woodcraft, or plastic enclosures. However, they’re not meant for large-scale or heavy-duty machining.

Where can you find the cheapest CNC machines?

Finding low-cost CNC machines isn't hard—but finding reliable ones takes more care.

You can find the cheapest CNC machines on online platforms like Amazon, AliExpress, Banggood, and specialized CNC kit websites.

While traditional suppliers sell machines at higher prices due to added services, online marketplaces connect you directly to manufacturers.

Trusted Sources for Budget CNC Machines:

| Platform | Features |

|---|---|

| Amazon | Fast shipping, easy returns, customer reviews |

| AliExpress | Direct-from-China pricing, wide selection |

| Banggood | Focus on electronics and hobbyist tools |

| Sainsmart | Known for affordable kits and routers |

| eBay | New or used machines at variable pricing |

Before purchasing, it’s important to:

- Read verified user reviews

- Compare machine specs with your project needs

- Check if software is included

- Confirm power supply matches your country

- Review seller support options

For those outside the U.S., many Chinese manufacturers offer direct export with better pricing. But warranty, import tax, and shipping times must be considered.

Also, some machines require technical knowledge for setup and use. Always check if assembly instructions, forums, or videos are available. Some buyers prefer brands with active user communities for better troubleshooting.

Buying a cheap CNC machine is possible without regret—if expectations and applications are aligned.

Conclusion

The cheapest CNC machines aren’t built for factories, but they open doors for learners, hobbyists, and small shops. With smart shopping and realistic expectations, even a few hundred dollars can unlock the power of computer-controlled cutting.