Understanding the differences between sinker EDM and wire EDM is crucial when choosing the right process for your manufacturing needs. Both are precision machining techniques, but they operate in different ways to achieve similar goals.

Sinker EDM and wire EDM are two types of electrical discharge machining (EDM) processes. Sinker EDM uses an electrode to create a cavity, while wire EDM uses a wire to cut through the material, making each suited for different types of parts and applications.

These two processes offer unique advantages and challenges. Let’s dive deeper into the characteristics of each and explore how to decide which one to use for specific tasks.

Why Compare Sinker and Wire EDM Processes?

Why is it important to compare sinker EDM and wire EDM? Understanding their differences helps in selecting the right process for achieving precision in complex part production.

Sinker EDM and wire EDM are both based on the principle of electrical discharge but are suited for different types of jobs. Comparing them helps in making an informed decision based on part geometry, material, and desired results.

Comparing sinker and wire EDM processes is crucial because both offer unique advantages depending on the type of machining required. Sinker EDM is often used when a cavity or a complex 3D shape is needed, while wire EDM is perfect for cutting thin sections and intricate details with straight edges. By understanding the key differences, manufacturers can optimize their process choices for efficiency, cost, and precision.

-

Process Difference:

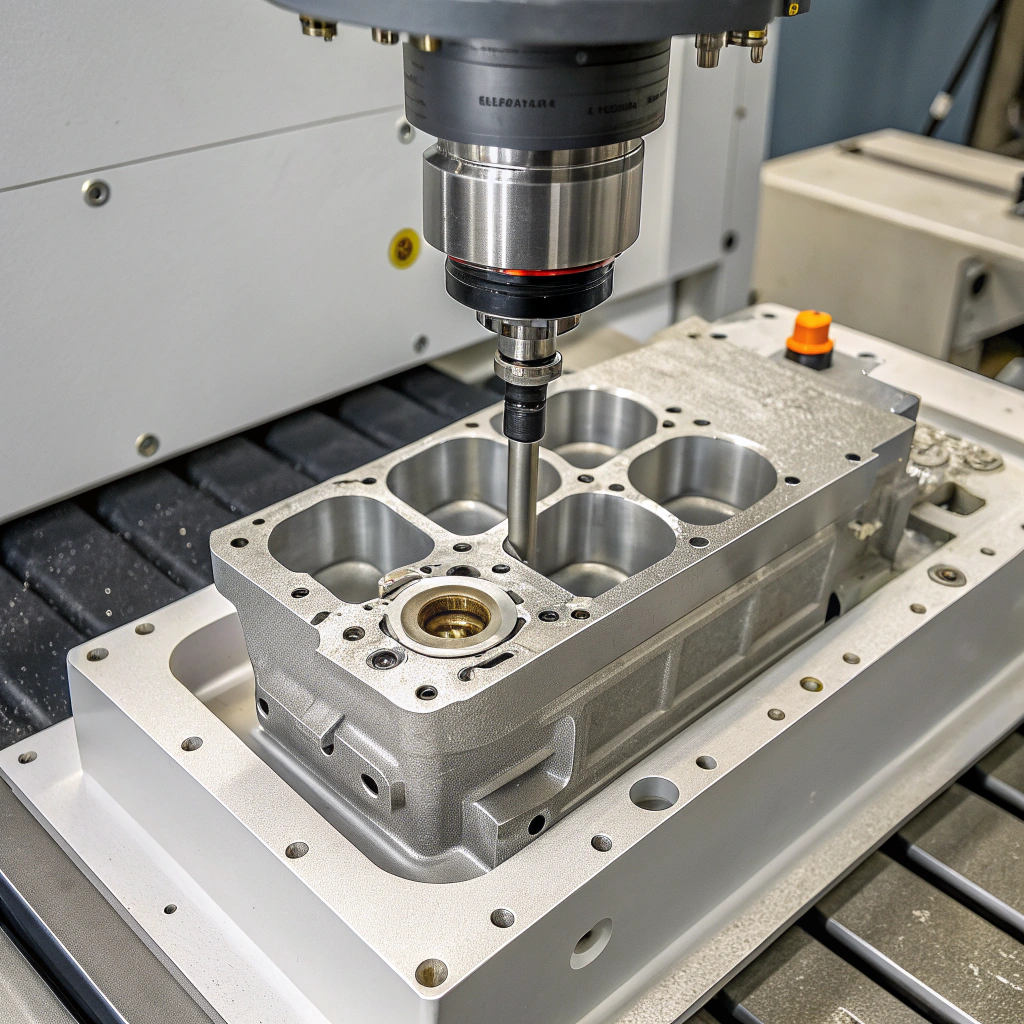

- Sinker EDM: Uses a shaped electrode to create the desired cavity or shape. The electrode is submerged into the workpiece, creating the shape by slowly eroding the material with controlled electrical discharges. Sinker EDM is ideal for deep cavities or parts with intricate 3D geometry.

- Wire EDM: Uses a continuously fed, electrically charged wire that cuts through the workpiece like a saw. Wire EDM is perfect for creating complex, highly accurate profiles, thin sections, and straight-line cuts, especially for parts that are difficult to machine with traditional methods.

-

Material Removal:

- Sinker EDM: Typically used for removing material in more defined areas, especially when the desired shape is 3D and requires a specific contour.

- Wire EDM: Primarily used for precise cutting of thin, flat parts and thin-walled sections, with minimal material loss.

-

Precision: Both processes are capable of high precision, but wire EDM typically offers more fine details for cutting thin shapes or parts with intricate patterns.

-

Speed: Wire EDM tends to be faster than sinker EDM, especially when cutting thin materials or parts with relatively simple geometries. Sinker EDM is often slower due to its deep cavity and more complex erosion process.

How to Select Between Sinker EDM and Wire EDM?

Deciding between sinker EDM and wire EDM depends on the nature of the part you are producing. What factors should you consider when making this decision?

Choosing between sinker and wire EDM depends on the part geometry, material, required precision, and production time. Each process offers benefits for different applications.

The selection of sinker or wire EDM depends largely on the part’s design, complexity, and material properties. Here’s how to approach the decision:

-

Geometry of the Part:

- If the part requires deep cavities, complex 3D shapes, or internal features, sinker EDM is the better choice. It allows for intricate shaping, such as creating molds, dies, or detailed cutouts.

- For parts that require cutting thin walls, profiles, or slots, wire EDM is ideal. It excels in making precise cuts along flat surfaces or intricate contours, especially in thin and hard materials.

-

Material Thickness:

- Wire EDM is often preferred for cutting thin sheets or sections of material, especially in materials like titanium, stainless steel, and hardened tool steels. Its ability to cut through thinner workpieces with minimal distortion is a key advantage.

- Sinker EDM can be used for thicker workpieces, where more material removal is necessary. The process is better suited for applications where deep or 3D cavities are required.

-

Precision:

- Both processes can achieve high precision, but wire EDM typically offers finer cutting capabilities with a tighter tolerance, making it perfect for creating fine details and delicate parts.

- Sinker EDM, on the other hand, is excellent for achieving high precision in creating larger, more complex shapes, especially where detailed internal features are necessary.

-

Production Volume:

- Wire EDM is faster for repetitive cuts or producing high quantities of similar parts, making it more cost-effective in large-volume production.

- Sinker EDM is generally better suited for smaller production runs or one-off parts that require highly specific shapes, as the process can take more time.

-

Cost and Time:

- Wire EDM tends to be more cost-effective for cutting flat shapes and intricate details, as it operates faster and requires fewer electrode replacements. It’s also easier to program and set up.

- Sinker EDM can be more expensive due to the slower process and the cost of specialized electrodes. However, it’s still the go-to method for parts with highly complex features that cannot be achieved with other machining methods.

What Are the Advancements in EDM Machining?

EDM technology is constantly evolving. What are the latest advancements that are improving sinker and wire EDM capabilities?

Recent advancements in EDM machining have led to faster processing times, greater precision, and more advanced materials. The future of EDM machining looks promising with improved automation, advanced software, and more sustainable practices.

Advancements in EDM technology are revolutionizing the way manufacturers approach precision machining. Here are some of the key developments:

-

Faster Processing Times:

Modern EDM machines have significantly reduced machining times, thanks to advancements in machine controls, faster electrode movements, and improved power supply systems. These improvements have increased overall efficiency and reduced lead times for parts production. -

Improved Precision and Surface Finish:

Newer EDM machines are capable of achieving even finer precision and better surface finishes. This has been made possible by the development of advanced power supply technology and more sophisticated control systems that offer more stable and consistent discharge cycles. The result is a smoother surface finish and greater detail in the final part. -

Automation and AI Integration:

Automation is playing a major role in improving EDM machining processes. Automated wire feeding systems, advanced electrode management, and AI-based predictive maintenance have made the processes more reliable and efficient. AI and machine learning algorithms are also helping to optimize machining parameters in real-time, allowing for higher-quality results and faster production times. -

Hybrid Technologies:

Hybrid machining technologies, such as combining EDM with additive manufacturing (3D printing), are gaining traction. This allows for the rapid creation of complex geometries and fine features, which are then fine-tuned with EDM processes. This combination reduces overall processing times and material waste. -

Sustainability:

As the manufacturing industry places more emphasis on sustainability, EDM machines are evolving to use less energy and generate less waste. The development of eco-friendly dielectric fluids, improved cooling systems, and energy-efficient machines are helping make EDM processes more environmentally friendly. -

Enhanced Material Capabilities:

Recent developments have expanded the range of materials that can be effectively machined with EDM. The increased precision and capability to handle difficult-to-machine materials like high-strength alloys, superalloys, and carbide materials mean that EDM can be used in even more demanding applications, such as aerospace and medical devices.

Conclusion

In conclusion, sinker EDM and wire EDM serve distinct purposes, each excelling in specific applications. Sinker EDM is ideal for creating deep, complex shapes and cavities, while wire EDM is better suited for cutting intricate profiles in thin materials. As technology advances, both processes are becoming faster, more precise, and more adaptable to modern manufacturing needs.