High‑end CNC machines can cost more than a small house. Many people wonder if the high price really matches the value.

The cost reflects top precision, speed, and advanced control systems that few machines can match.

That idea leads to many deeper questions. What makes a CNC machine extremely expensive? Why do some industries pay for them without hesitation? We explore these points below.

How do top-tier CNC machines justify their cost?

Top-tier CNC machines deliver dramatic gains in quality, speed, and reliability. They save time, reduce waste, and pay for themselves in tough projects.

Most expensive CNC machines deliver ultra‑tight tolerances under extreme conditions. They hold micron‑level accuracy with heavy loads or at high speed.

These machines often integrate advanced controls, coolant systems, vibration dampening, and high‑end spindles. Because of that capability, they cut exotic metals cleanly and repeatably without breakdowns.

That justification sounds technical. It also matters on the shop floor. When a machine costs, say, over half a million dollars, the buyer expects it to handle the hardest jobs every single day. With cheaper machines, one may run into quality issues or frequent maintenance. With top-tier machines, such issues drop significantly. For some buyers, the lowered risk of scrap or rework alone can earn back the cost quickly.

Strong precision and waste reduction

Top-tier CNC machines keep tolerances within microns across many parts. That means each part comes out almost identical. When working with expensive materials like titanium, aluminum alloys, or hardened steel, material cost is high. If parts fail quality checks, the waste becomes very costly. In that case, a machine that reduces scrap by 5‑10% can save more money than its higher price difference.

High uptime and reliability

Expensive machines use high‑quality components: spindles, bearings, coolant systems, and electronics. They often come from respected manufacturers with tight quality control. They also have better diagnostics and maintenance alerts. That means they break down less often. Less downtime means production stays steady. Steady production means predictable supply and delivery. That reliability often justifies the premium cost.

Lower labor cost per part over time

With high precision and reliability, operators spend less time inspecting parts or reworking rejects. Also, high‑end machines can often run unattended overnight or for long shifts. That reduces labor costs per part. Over time, the cost per piece drops significantly compared with lower‑end machines.

Why do aerospace firms invest in ultra-premium CNC systems?

Aerospace firms demand extraordinary quality. Even small mistakes can cause major failures in aircraft or spacecraft. For that, they often pick only the best CNC machines.

Aerospace makers use ultra-premium CNC machines to avoid critical failures, reduce scrap, and meet certification standards for complex, high-value parts.

These firms machine components from expensive alloys like titanium or high‑strength aluminum. They shape critical parts: turbine blades, structural brackets, engine components, and other parts that face extreme stress. A tiny flaw might cause failure at high speed or under load.

Safety and certification demands

Aerospace parts often must follow strict certification requirements. Parts must meet tight tolerances, and sometimes undergo fatigue testing, stress testing, or ultrasonic inspection. If the part fails, the batch is rejected. For a firm, that is a big financial loss.

Ultra‑premium CNC machines reduce risk. They can hit the required tolerance every time. They maintain tight surface finish and structural accuracy. That helps parts pass tests reliably.

Working with costly materials

Materials used by aerospace makers are pricey. Titanium, Inconel, high‑strength aluminum alloys may cost hundreds of dollars per kilo. If a part fails due to poor machining, material is wasted. That becomes a big loss. Spending on top CNC machines reduces that risk.

Complex geometries and precision machining

Modern aerospace parts have complex shapes. They often involve 5‑axis or multi‑axis machining, curved surfaces, and tight internal cavities. Ultra‑premium CNC machines handle these geometries smoothly. They keep consistent tool paths, avoid chatter, and ensure symmetrical quality.

They also offer advanced coolant and chip evacuation systems. When cutting tough metals, heat and chips can distort parts. High‑end machines avoid that. The result is parts that meet the design exactly.

Long-term cost savings in critical production

A single defective part in flight components can cause huge costs or catastrophes. For that reason, firms accept high initial cost. They value long-term reliability, material savings, and predictable performance.

Which features drive CNC machine prices upward?

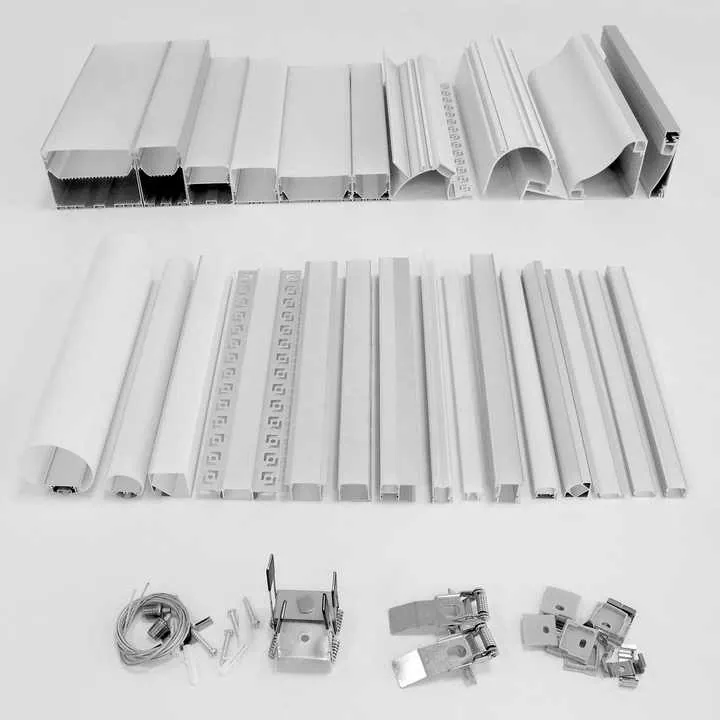

High price often means many advanced features. These features improve precision, speed, reliability. They demand better design, higher quality components, and more complex manufacturing.

The most expensive CNC machines include features like multi-axis control, ultra-high precision, advanced cooling systems, and automation—all of which add to the cost.

| Feature category | What it adds to machine | How it raises cost |

|---|---|---|

| High-speed, high-power spindle | Allows cutting hard materials at fast feed rates | Needs stronger bearings, cooling, vibration control |

| Multi-axis control (4/5/6 axes) | Lets machine complex shapes in one setup | Requires complex control software and hardware |

| Rigid frame and high damping | Reduces vibration, increases accuracy | Uses heavy, expensive castings or composite structure |

| Advanced coolant / chip removal | Keeps material stable during cut | Adds pumps, nozzles, channels — engineering cost |

| Precision linear bearings / guides | Ensures micron-level positioning | Uses high-grade components, tight tolerances in build |

| Automated tool changers and pallet systems | Speeds up batch production | Adds mechanical complexity and cost |

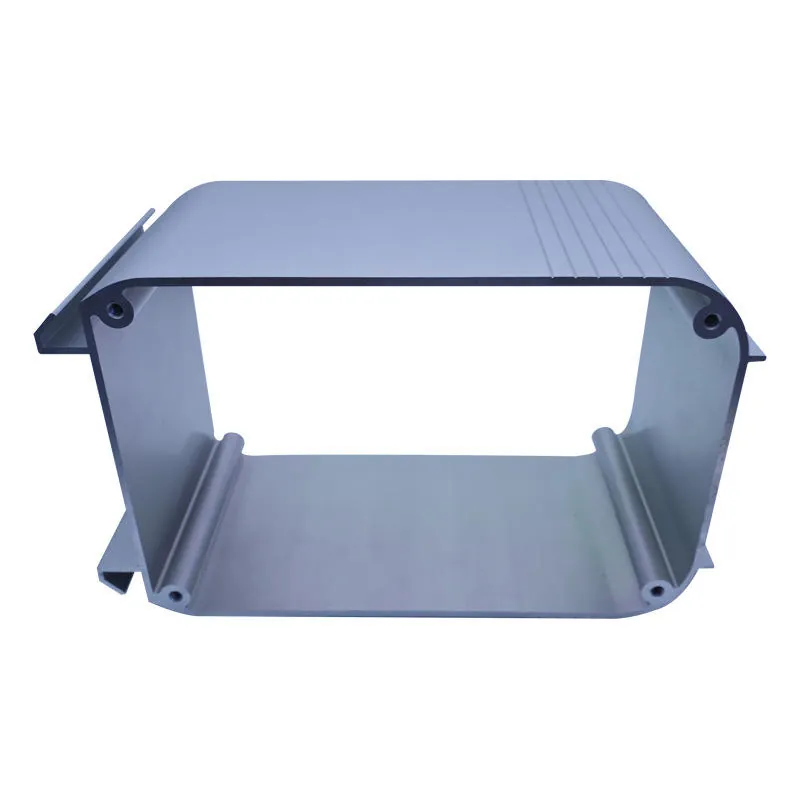

| Enclosures and safety systems | Protects operators and environment | Adds sheet metal work, sensors, safety design |

| Integrated software & control systems | Allows complex CNC code, automation, monitoring | Requires software development, testing, licensing |

Another factor is build quality and long-term durability. High‑end machines are built to run for years without replacement. That means better parts, thicker frames, higher quality welds or castings.

Also, manufacturer support adds value. Many premium machines come with extended warranties, on‑site installation, setup, calibration, and training. That support adds cost but gives buyer confidence.

Where are high-end CNC systems typically used?

High-end CNC systems find homes in industries that demand precision, repeatability, and reliability. They appear where defects are unacceptable or materials are expensive.

They are commonly used in aerospace, medical device, motorsport, tooling, and energy industries—where quality cannot be compromised.

| Industry / Use Case | What they do with CNC machines | Why they need high‑end systems |

|---|---|---|

| Aerospace parts | Turbine blades, structural brackets, engine housings | Tight tolerances, expensive alloys, safety standards |

| Medical devices | Surgical instruments, implants, prosthetics | Biocompatibility, cleanliness, precision shapes |

| Automotive high performance & motorsport | Engine components, chassis parts, custom brackets | Strength, weight-saving, tight tolerances |

| Energy (oil & gas, wind turbines) | Turbine housings, drill heads, custom parts | Harsh environments, heavy materials, precision fits |

| Tool & die making | Molds, dies for plastics or metal forging | High precision, long tool life, wear resistance |

| Prototyping & R&D | Experimental parts, small batch, complex geometry | Flexibility, precision, quick turnover |

Also, many of these parts are not just functional. Surface finish, internal geometry, strength, and weight all matter. That pushes need for advanced CNC features: multi‑axis machining, complex contours, precise tool paths, accurate coolant and chip handling. Cheap machines simply cannot do such jobs reliably.

Conclusion

Expensive CNC machines command high prices because they offer unmatched precision, reliability, and power. For industries where quality and consistency matter, they are not optional — they are essential. High cost reflects real value.