A tolerance press fit refers to the intentional interference between two mating parts, typically a shaft and a hole, in which one part is slightly larger than the other. The interference causes the parts to fit tightly together when pressed, creating a strong, secure connection without the need for additional fasteners or welding.

Tolerance press fit is a type of mechanical fastening where the components are designed with specific tolerances to ensure that the interference fit provides a tight, secure bond without causing damage to the parts. This method is commonly used in applications where precision is critical, such as in automotive, aerospace, and industrial machinery.

Press fits are essential in ensuring that parts are aligned and hold securely under stress or pressure. The press fit is achieved by controlling the dimensions of the parts and the interference, ensuring the assembly process is smooth and that the final product is stable.

What Are the Benefits of a Tolerance Press Fit?

Tolerance press fits offer several advantages over other mechanical fastening methods, such as bolts, screws, or welding. These benefits make press fits an attractive option in applications where space constraints, reliability, and cost-effectiveness are important.

Tolerance press fits are beneficial because they provide a strong and durable connection without the need for additional components. They are often more reliable, cost-effective, and simpler to implement than other methods. Here’s why tolerance press fits are favored in various industries.

Reduced Assembly Complexity

One of the major benefits of a tolerance press fit is that it eliminates the need for extra fasteners or adhesives. This not only reduces the number of components needed for assembly but also simplifies the manufacturing process. A press fit only requires the correct tolerances for the parts, making it an efficient and straightforward method.

Improved Strength and Stability

The interference between the mating parts in a press fit creates a strong bond. This bond can withstand a significant amount of stress, vibration, and torque, making press fits ideal for applications requiring a high level of durability and reliability. This is particularly important in industries like aerospace, where the safety and reliability of connections are critical.

Cost-Effective

Since a press fit doesn’t require additional fasteners, welding, or adhesives, it reduces the overall cost of the assembly process. There’s also no need for complex machinery or time-consuming processes, as press fits can be achieved using simple tools like hydraulic presses. This makes it a cost-effective solution for large-scale production.

Space Efficiency

Press fits are compact and don’t require extra space for fasteners or welding. This makes them ideal for applications where space is at a premium. A press fit allows parts to fit securely without additional external components, making it particularly useful in industries such as automotive and electronics.

How to Achieve Proper Press Fit Tolerance?

Achieving the proper press fit tolerance is critical to ensuring that the interference between parts provides a secure connection without causing damage. The success of a press fit depends on selecting the right materials, controlling tolerances, and ensuring that the assembly process is conducted correctly.

To achieve a proper press fit tolerance, it’s necessary to carefully calculate and control the interference between the parts, select the right materials, and consider the assembly process. Here are the key steps in ensuring a successful press fit.

Step 1: Select the Correct Interference Fit

The interference fit is determined by the difference in size between the two mating parts—one part is slightly larger than the other. This interference creates the friction necessary for a tight fit. The amount of interference depends on the application and the materials being used, as too much interference can cause damage to the parts.

There are different types of fits based on the amount of interference:

| Fit Type | Interference | Application |

|---|---|---|

| Light Press Fit | Small interference | Bearings, small shafts, or housings |

| Medium Press Fit | Moderate interference | Parts subjected to moderate loads |

| Heavy Press Fit | Large interference | High-stress or high-torque applications |

Step 2: Control Tolerances

The tolerances of both the hole and the shaft are crucial in achieving the desired interference fit. A shaft should be slightly oversized, and the hole should be slightly undersized. The difference between these dimensions creates the interference that holds the parts together. Calculating these tolerances accurately is essential to prevent excessive force or inadequate fit.

For example, a typical tolerance for a press fit might be a shaft diameter of 50 mm with a hole of 50.05 mm. This difference of 0.05 mm creates the interference that allows the parts to fit securely.

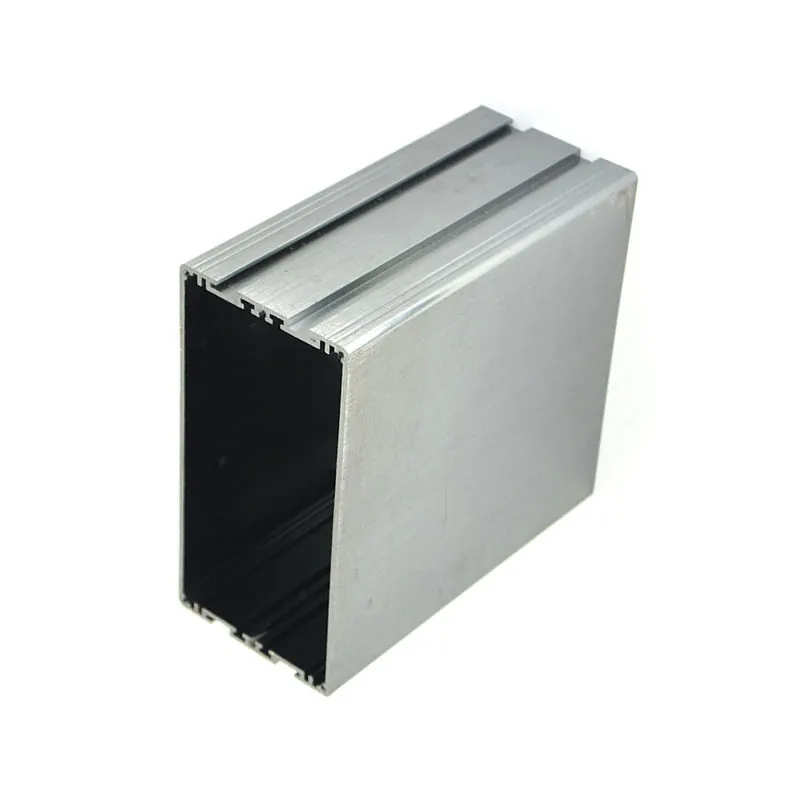

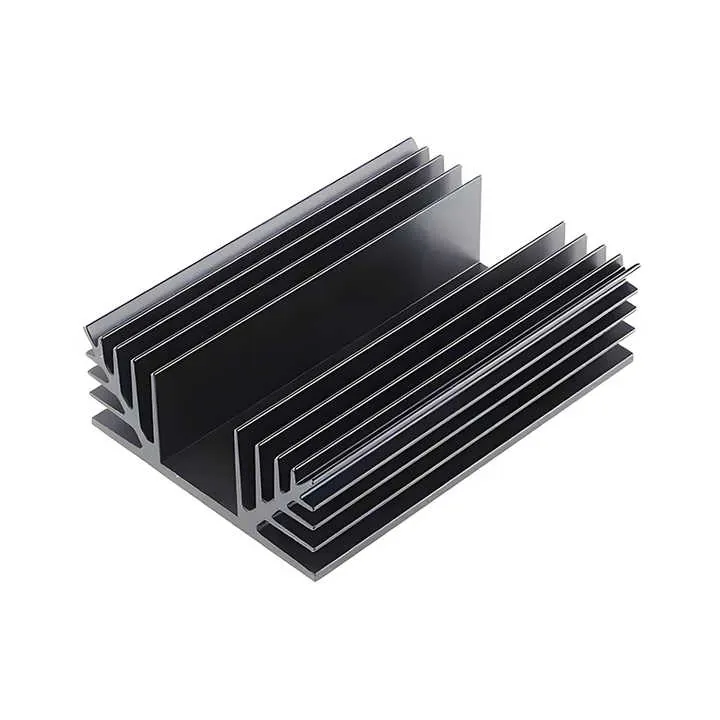

Step 3: Choose Appropriate Materials

Material properties play an essential role in the press fit process. For instance, materials with higher elasticity, such as aluminum or steel, are more suitable for press fits because they can tolerate the interference without cracking or deforming. The combination of materials will affect the amount of interference required, so careful selection is important.

Step 4: Use the Correct Pressing Force

The amount of force applied during the press fitting process should be controlled to ensure that the parts are inserted with the correct amount of interference without causing damage. The force should be sufficient to ensure a tight fit but not excessive to the point where the parts are distorted or damaged. Hydraulic presses are often used to apply controlled force.

What Are the New Trends in Press Fit Engineering?

As manufacturing processes evolve, so does the technology behind press fits. New trends in press fit engineering focus on improving precision, automation, and material science to create more efficient, reliable, and cost-effective connections.

New trends in press fit engineering are driven by advancements in automation, materials, and simulation technologies. These innovations aim to improve the accuracy, speed, and efficiency of the press fit process while reducing costs and improving the overall quality of the assembly.

Automation and Robotic Pressing

Automation is one of the most significant trends in press fit engineering. Robotic systems and automated presses are increasingly used to improve the speed and accuracy of the press fit process. These automated systems can apply the correct amount of force, handle higher volumes of parts, and ensure consistency in the press fit process. This reduces human error and increases the overall efficiency of manufacturing.

Advanced Simulation Software

Advanced simulation software is being used to predict the behavior of press fits before they are physically created. These tools allow engineers to simulate the press fitting process and make adjustments to the tolerances and materials to ensure a successful fit. By using simulation, manufacturers can avoid costly mistakes and optimize the press fit process for maximum efficiency.

New Materials and Coatings

The development of new materials and coatings is improving the performance and durability of press fit connections. For example, advanced coatings are being used to reduce friction during the press fitting process, making it easier to achieve a tight fit without damaging the parts. New materials with better thermal properties and elasticity are also making it easier to design parts that can withstand higher loads and stresses.

Sustainable Manufacturing Practices

As sustainability becomes a priority in manufacturing, engineers are increasingly looking for ways to reduce waste and energy consumption in the press fit process. By optimizing press fit tolerances and using automated systems, manufacturers can reduce scrap and improve the overall sustainability of the process. Additionally, the use of recyclable materials and energy-efficient presses is gaining traction in press fit engineering.

Conclusion

In conclusion, tolerance press fit is a highly effective method for creating strong, reliable connections between parts without the need for additional fasteners or welding. By understanding how to achieve proper press fit tolerances, manufacturers can optimize their processes to ensure secure, durable connections. With the ongoing trends in automation, simulation, and material advancements, press fit engineering is becoming more efficient, precise, and sustainable.