In the mid-20th century, manufacturers faced rising labor costs and demand for higher precision. Manual machines couldn't keep up. Something had to change. CNC was the answer.

The first CNC machine was developed in the late 1940s by John T. Parsons and Frank Stulen, funded by the U.S. Air Force. It marked the beginning of automated precision manufacturing.

It started with punched tape and evolved into today’s high-speed, high-precision digital machining. This article explores the origins, innovations, and impacts of CNC.

How did early CNC machines function?

Manual machine tools required constant operator control. They were slow, limited, and prone to error. CNC offered something new: automation through coded instructions.

Early CNC machines used punched paper tape to guide machine movements based on X, Y, and Z axis coordinates. These instructions were mechanical and later digitized.

The Mechanism Behind Early CNC

The first CNC machine was a modified milling machine. It used punched tape, like the kind used in player pianos, to control movement. Each hole on the tape represented a command: move right, up, down, or cut. These commands translated to movement along three axes.

The earliest systems were called NC, short for Numerical Control. Computers were not yet part of the system. Instead, motors and servomechanisms followed mechanical signals to drive the tool.

Key Features of Early CNC Machines

| Feature | Description |

|---|---|

| Control Medium | Punched paper tape |

| Axes Controlled | Usually X, Y, Z (3 axes) |

| Input Type | Numeric code |

| Feedback Mechanism | Servos and motors |

| Machine Type | Primarily milling machines |

These machines still needed human input. An engineer had to write the program by hand. Mistakes in the code meant errors in production.

Transition from NC to CNC

By the 1960s, digital computers were introduced. These systems allowed more complex operations. Engineers could store programs digitally and reuse them. Accuracy improved. So did efficiency.

This shift also paved the way for CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). These tools turned digital blueprints into automated cutting paths.

Why was CNC technology revolutionary?

Manufacturers were desperate for a better way to produce consistent parts. Manual machining had limits. CNC changed everything.

CNC technology revolutionized manufacturing by increasing precision, reducing human error, and allowing mass production of complex parts with consistency.

Why CNC Changed the Game

Before CNC, skilled machinists controlled every cut. If one operator was better than another, part quality varied. With CNC, machines followed exact instructions every time. That meant every product came out the same.

CNC also made it possible to cut materials like titanium or hardened steel more effectively. It enabled complex 3D shapes impossible with hand tools. A task that once took hours could now take minutes.

Benefits of CNC Over Manual Machining

| Advantage | Manual Machining | CNC Machining |

|---|---|---|

| Precision | Varies by operator | Consistently high |

| Reproducibility | Difficult | Easy and exact |

| Speed | Slower | Much faster |

| Complexity | Limited by skill | Supports intricate parts |

| Labor Cost | High | Lower over time |

Impact on Global Manufacturing

With CNC, companies didn't need a large staff of skilled machinists. Instead, one operator could manage multiple machines. This reduced costs and made it easier for small manufacturers to compete globally.

Industries like aerospace, automotive, and electronics accelerated production without sacrificing quality. They could prototype faster, respond to market changes quicker, and scale up effortlessly.

Which industries adopted CNC first?

Some industries need tighter tolerances than others. For them, small errors mean big consequences. They were the first to embrace CNC.

Aerospace and defense industries were the earliest adopters of CNC due to their need for high precision and repeatability in complex metal parts.

CNC in Aerospace and Defense

Aircraft components must fit perfectly and withstand extreme forces. Manual errors could mean failure in flight. CNC offered a new level of control. The U.S. Air Force helped fund the first CNC project, hoping to improve jet engine parts.

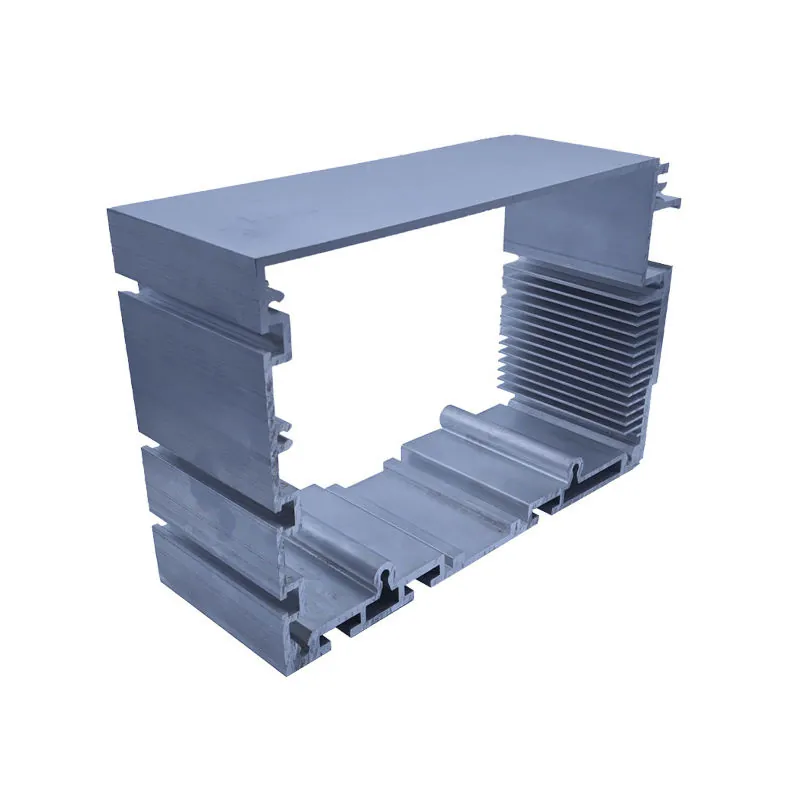

Complex airframe structures also required intricate geometry. CNC machines delivered that complexity without sacrificing strength.

By the 1960s, defense contractors and airplane manufacturers were using CNC widely. It became the standard for producing reliable components at scale.

Early Industrial Applications

Other sectors quickly followed:

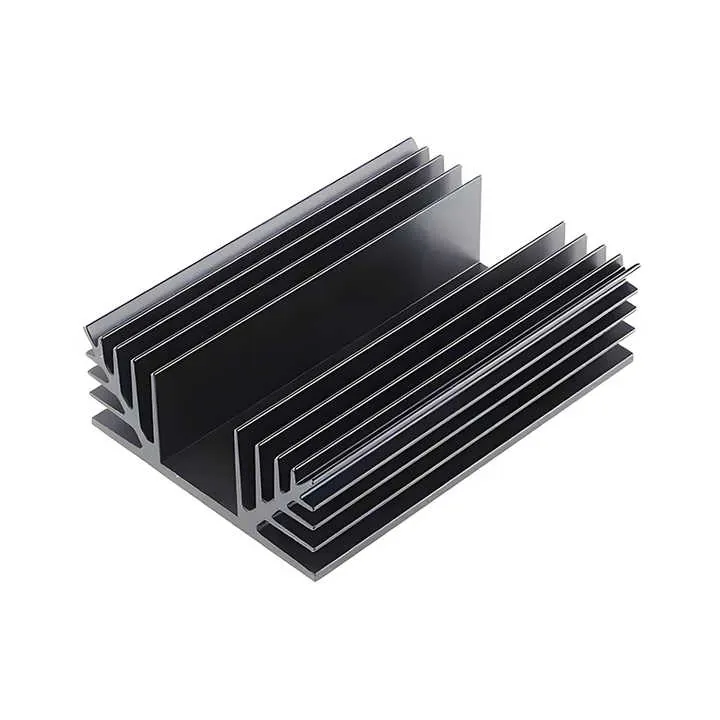

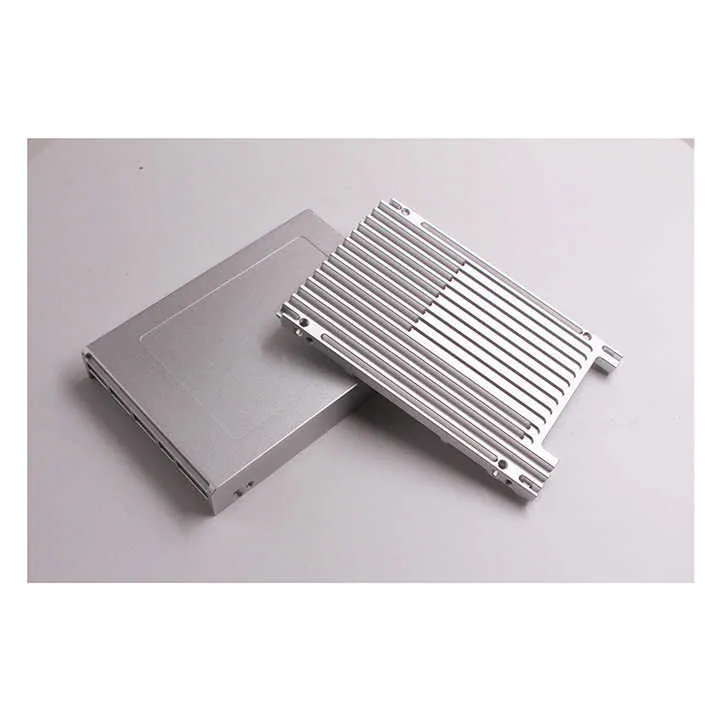

- Automotive: Used CNC for engine blocks, gear systems, and later, custom parts.

- Medical: Required precision for implants, surgical tools, and diagnostics.

- Electronics: Needed CNC for tiny, consistent enclosures and circuit components.

Common Early CNC Products

| Industry | CNC Applications |

|---|---|

| Aerospace | Turbine blades, wing parts, engine mounts |

| Automotive | Cylinder heads, transmission gears |

| Medical | Bone screws, joint replacements, scalpels |

| Electronics | Housings, connectors, PCBs |

These industries needed not just speed but exactness. CNC gave both.

Where was the first CNC machine used?

CNC didn’t emerge from a factory. It was born in a lab, developed with military funding, and aimed at solving a very specific challenge.

The first CNC machine was used at MIT's Servomechanisms Laboratory, funded by the U.S. Air Force to improve aircraft part production.

Origins at MIT

In 1949, John T. Parsons was working on helicopter blades. He needed a better way to cut complex curves. Along with Frank Stulen, he partnered with MIT to develop a machine that could follow coordinates automatically.

The result was the first NC milling machine. It used punched tape to feed position data into motors. This system was installed at the MIT Servomechanisms Lab and used to build aircraft parts.

This machine didn’t enter a factory right away. It was experimental. But the Air Force saw its potential and pushed for broader adoption.

CNC Spreads Beyond the Lab

Once the idea proved successful, manufacturers began adapting it. General Electric, Boeing, and other major companies adopted CNC quickly. Machine tool builders started designing new models around CNC principles.

By the 1970s, CNC was no longer niche. It was a necessity for staying competitive. The innovation that started at MIT soon became global.

Conclusion

CNC began as a military experiment and grew into the backbone of modern manufacturing. From punched tape to powerful software, its evolution shows what happens when innovation meets precision. CNC machines changed how we build things—and where we build them.