Manufacturing was once slow and manual, costing time and money. Then came the idea of using numbers to control machines. This changed everything.

The first CNC machine came from the push to automate machining after World War II, with the earliest work starting in the 1940s and a prototype complete by 1952.

Today’s CNC machines are everywhere, but the journey began decades ago. Let’s look closer at how it started and how it grew into modern manufacturing.

Who invented the first CNC machine?

The metal industry struggled with precision before CNC. Manual work meant slow progress and more mistakes. That sparked the search for automation.

John T. Parsons is credited as the key figure behind the first numerical control systems that led to CNC machines, with early work beginning in 1949.

In 1949, John T. Parsons began working with the U.S. Air Force to solve a challenge—making helicopter blades. He partnered with IBM and used a computer to calculate complex curves. These numbers were converted into punch cards. Those cards guided motors to move a milling machine in very precise ways.

Parsons’ concept was not yet CNC as we know it, but it introduced the idea of using code to control tools. A few years later, Richard Kegg teamed up with MIT to create the first actual CNC milling machine in 1952. It used punched tape and servomechanisms to control tool movements.

Early Innovators of CNC

| Name | Contribution | Timeline |

|---|---|---|

| John T. Parsons | Invented numerical control concept | 1949 |

| IBM | Supplied calculator for coordinate data | 1949 |

| Richard Kegg & MIT | Built first functional CNC milling machine | 1952 |

This collaboration laid the groundwork for modern CNC machines. Parsons’ vision and Kegg’s engineering brought digital thinking into physical machining.

How did the development of CNC machines begin?

Before CNC, operators used hands to guide cutting tools. That meant every part could be slightly different. It was slow, tiring, and inconsistent.

The development of CNC machines began as an evolution of numerical control, using punch cards and motors to improve consistency and reduce human error.

World War II pushed manufacturing to its limits. Airplanes needed high-precision parts, and there weren’t enough skilled workers. That made automation essential. Engineers began exploring ways to turn math into motion.

The earliest machines used punch tape, motors, and servomechanisms. These parts turned coded numbers into tool paths. Early NC (Numerical Control) machines could follow curves and shapes that human hands could not match.

The Shift from NC to CNC

- 1949: Numerical control begins with coordinate punch cards.

- 1952: First NC milling machine is completed at MIT.

- 1960s: Servo systems improve speed and accuracy.

- 1970s: Computers replace punch tape—true CNC arrives.

As electronics improved, punched cards gave way to magnetic tape and later floppy disks. By the 1970s, microprocessors allowed machines to store and edit programs internally. That turned NC into CNC.

Programming also changed. G-code became the standard language. Operators could type in instructions instead of physically changing tapes. CNC machines became faster, smarter, and easier to use.

What were the initial uses of CNC machines?

The first CNC machines didn’t go to car factories or furniture shops. They were used in critical industries where precision meant safety and performance.

The initial uses of CNC machines were in aerospace and defense, where complex parts with tight tolerances were needed.

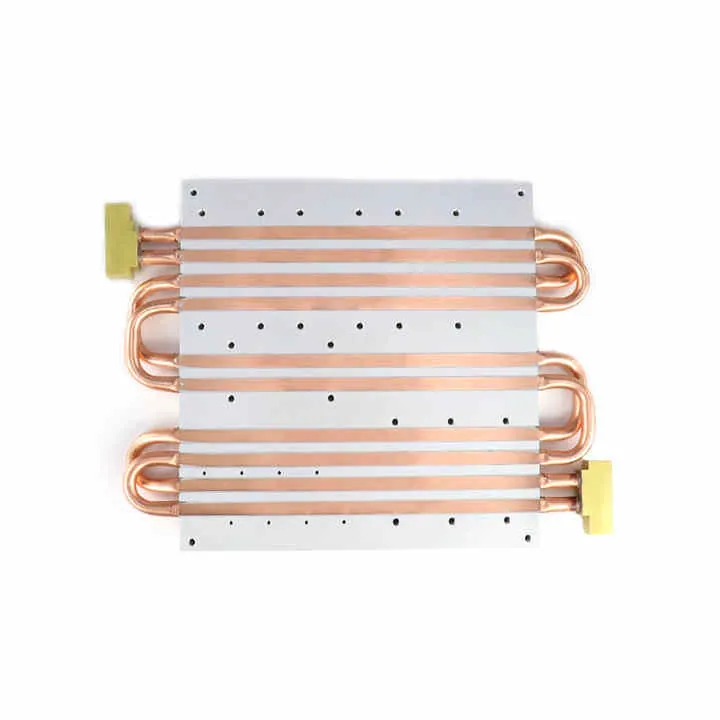

Helicopter blades, missile parts, and aircraft panels were too complex to make by hand. CNC made it possible to machine those parts with precision that was impossible before. Machines could follow exact paths repeatedly.

As CNC proved its value, it spread to other industries.

Industries That First Used CNC

| Industry | Application |

|---|---|

| Aerospace | Machining of turbine blades and fuselage frames |

| Defense | Components for guided weapons and radar systems |

| Automotive | Cylinder heads, gearboxes, and engine blocks |

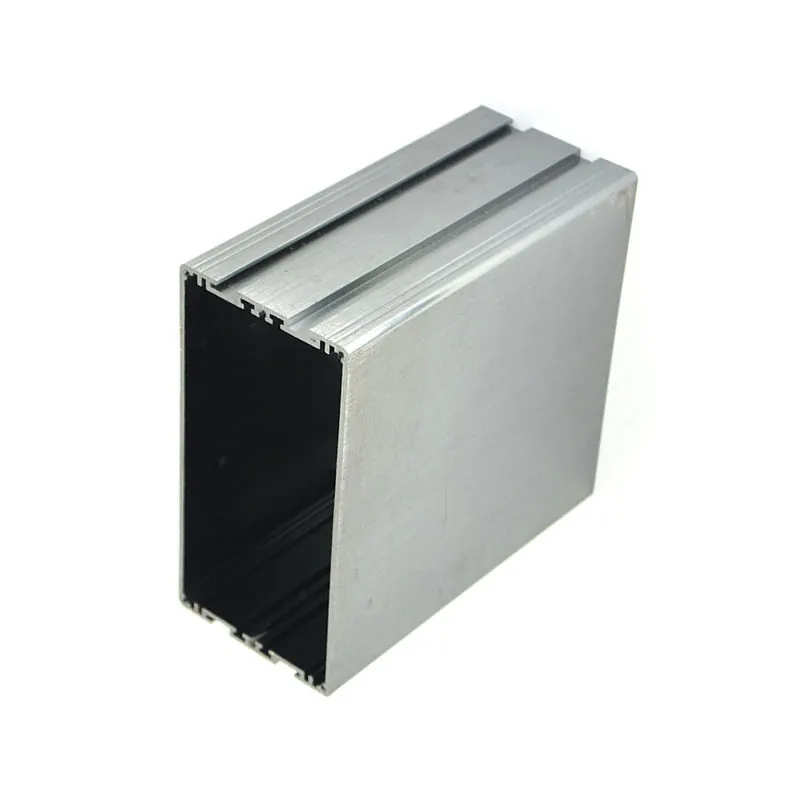

By the 1970s, the auto industry saw its value. CNC allowed car makers to build engines faster and with fewer defects. The electronics industry also started using CNC for making connectors, housings, and PCB frames.

These early uses showed how CNC could reduce labor, improve quality, and boost speed. Once businesses saw those benefits, CNC adoption grew rapidly.

How has CNC technology evolved since its creation?

The first CNC machine filled a room and took hours to program. Today, CNC machines fit on a table and can change tools in seconds.

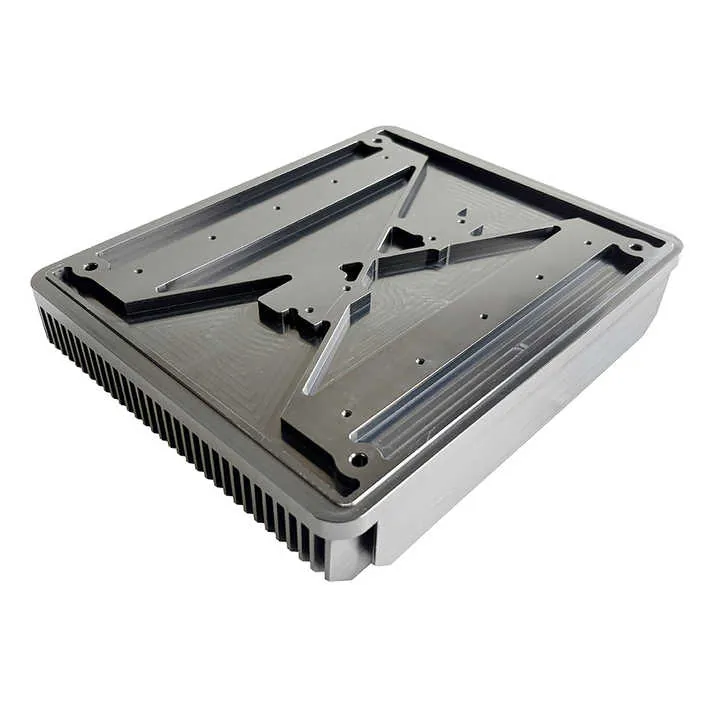

Since its creation, CNC technology has evolved into a digital, multi-axis system capable of complex machining with high automation and real-time monitoring.

Modern CNC machines are faster, smarter, and more flexible. They can read 3D CAD files directly, choose the right tools, and even correct small mistakes on the fly. They are linked to networks, so managers can monitor machines from anywhere.

Key Evolutions in CNC

1. Software

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) allow engineers to design parts and generate toolpaths without manual coding. Modern software can simulate machining before cutting begins.

2. Hardware

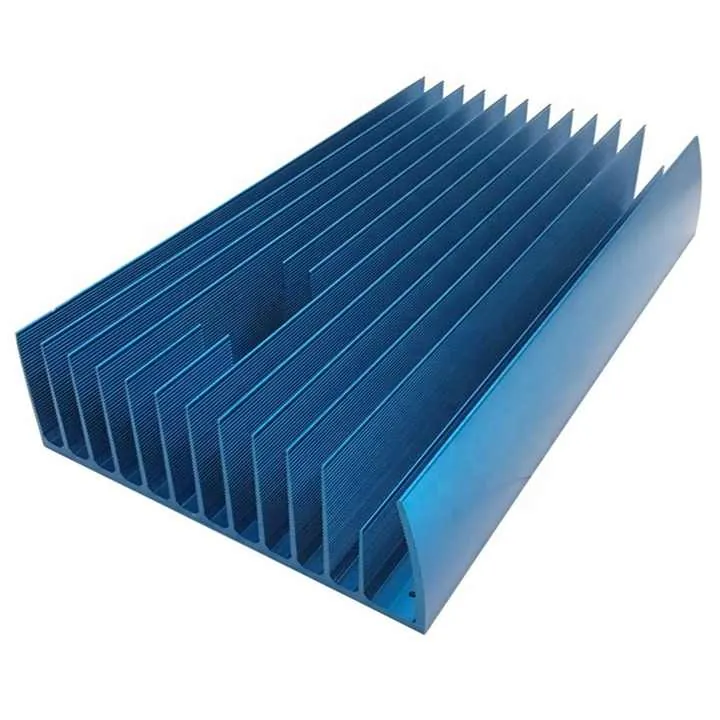

Today’s CNC machines include:

- Touchscreens

- Tool changers

- 5-axis or 7-axis movement

- Robotic part loaders

These features allow the machine to operate with little human help.

3. Connectivity

Factories now use smart systems that link machines with sensors, maintenance alerts, and cloud data. This trend is called Industry 4.0.

| Evolution Area | 1950s | Today |

|---|---|---|

| Control | Punch card | Digital computer |

| Motion | 2–3 axis | 5+ axis |

| Programming | Manual tape | CAD/CAM software |

| Feedback | None | Live monitoring, sensors |

CNC machines now make everything from airplane engines to dental implants. Their accuracy, speed, and automation have made them essential for modern manufacturing.

Conclusion

The first CNC machine started as a wartime solution and became a global manufacturing standard. From punched cards to digital systems, CNC has transformed how we make parts—faster, better, and smarter.