I often ask: can 3D printing really take over CNC machining in factories?

The thought feels exciting and scary at the same time.

3D printing brings new freedom and speed.

CNC keeps being reliable and precise.

Both shine in different ways.

In many cases they may work side by side.

How do 3D printing and CNC differ?

The change of tools can cause hope and worry.

I know many people see 3D printing as a magic wand.

That view can make some neglect real differences fast.

3D printing and CNC are very different in how they make parts.

3D printing builds layer by layer using additive process. CNC cuts away material from a block using subtractive process. They use different machines, different workflows, and different skills.

When we look deeper, the differences are clear.

What is additive vs subtractive?

- Additive (3D printing): Printer uses plastic, resin or metal powders. It adds material layer by layer. The part gradually appears.

- Subtractive (CNC machining): Machine starts with a solid block. It cuts, mills, drills and shapes. It removes material until final part appears.

This difference changes cost, time, waste, and final quality.

Compare side by side

| Feature | 3D printing (additive) | CNC machining (subtractive) |

|---|---|---|

| Material use | Uses only needed material. Low waste. | Starts with block. Much waste from cutting. |

| Shape freedom | Can make complex, organic shapes easily. | Best for straight shapes, plain curves, simple geometry. |

| Surface finish | Rougher surface, needs post‑processing often. | Usually smooth and accurate surface. |

| Speed for small runs | Fast once setup done. Good for prototypes or small batches. | Setup and programming take time. Slower for small runs. |

| Material strength (some types) | Can be lower for some materials (depends on printing method). | Strong and consistent, good for functional parts. |

These facts show big differences.

Why they feel so different in practice

3D printing can take hours or days depending on part size. Each layer adds slowly. Sometimes part shrinks or warps. Printer needs calibration. Materials can be limited.

CNC machines run fast once they are set up. The block stays firm. Cuts are precise. But setup is complex. Mistakes can waste expensive material.

In real work, additive and subtractive often serve very different needs.

I see 3D printing shine when creative shape, small quantity, low waste matter. I see CNC thrive when part needs strength, precision, and smooth finish.

That simple difference often decides which method fits a job best.

Why CNC remains indispensable?

People often rush to adopt new tools. I also like new stuff. But CNC stays crucial.

Many jobs still need a level of strength and accuracy that 3D printing cannot give.

CNC machining remains vital because it delivers strength, precision, and reliable surface finish that 3D printing often cannot match.

Many industries require tight tolerances, stable materials, and high repeatability. CNC does that day after day.

I look at factories and shops around the world. CNC machines are still everywhere. They shape metal, plastic, wood. They run large jobs or many identical parts.

Strength and material quality

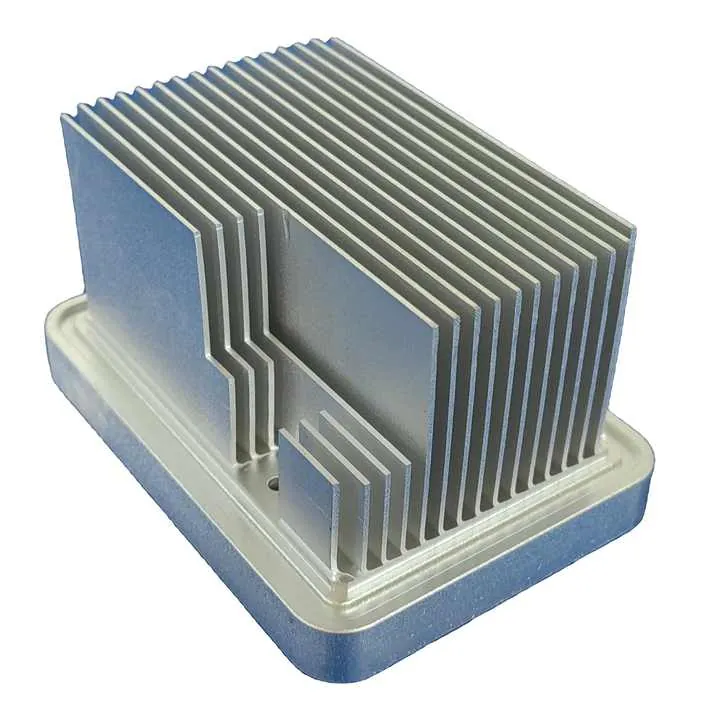

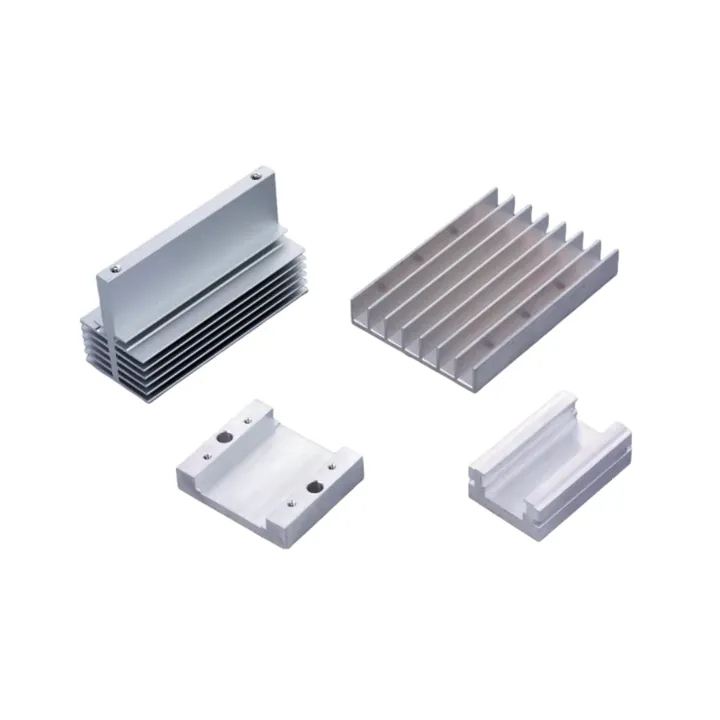

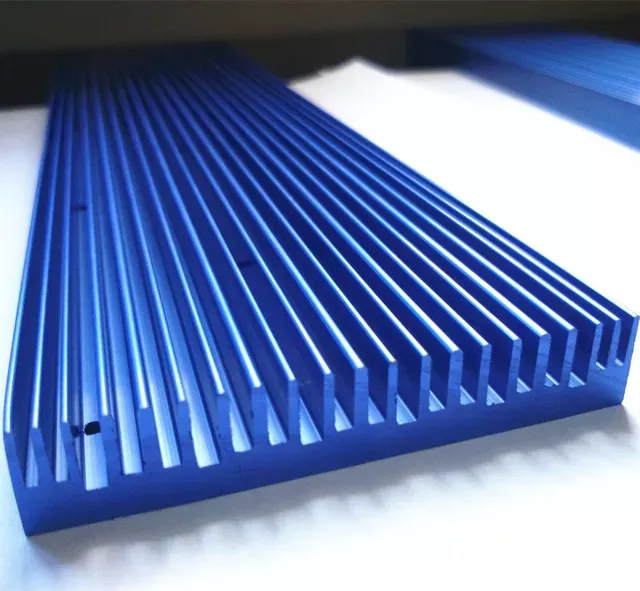

CNC machining works with solid blocks of material. For metals like aluminium, steel, brass, the final part retains full strength of the material.

3D printing metal or strong plastic is possible. But printed parts often have tiny voids, layer bonding issues or uneven density. That can make parts weaker or unpredictable for heavy loads.

When part is a structural element, CNC is often safer.

Precision and surface finish

CNC tools use sharp cutters and rigid setups. They clamp the workpiece firmly. The cut path is controlled with fine resolution. Final parts often meet tight tolerances: often within fractions of a millimeter. Surfaces are smooth or can be polished.

3D printing often leaves visible layers. Printed surface may need sanding, coating, or machining again for smoothness. This adds extra time and cost.

Reliability and repeatability

Once CNC program is set, the machine can make dozens or hundreds of identical parts consistently. Each part comes nearly the same as last. This repeatability matters for mass production or parts that must match precisely.

3D printing may have variation. Material quality, printer calibration, environmental conditions can affect results. For critical parts, this variation is risky.

Cost and waste for large runs

For a large batch of parts, starting with a block may mean waste. But cost per part falls because machine time and labor are steady. Materials like aluminium are cheap per kg compared with plastic powders or special metal powders used for printing.

3D printing may start cheap for one part. But if you print many, cost adds up. Material cost, printer wear, print failures make it less efficient.

Regulatory and industrial standards

Many industries—automotive, aerospace, heavy machinery—need parts certified to standards for strength, traceability, and material origin. CNC machining meets those standards more often.

In these fields, regulatory pressure keeps CNC in place.

Because of all these, CNC remains indispensable even when 3D printing grows.

Which jobs fit 3D printing?

People often think 3D printing can do any job. That is not true.

But 3D printing suits certain jobs very well.

Jobs that need complex shapes, quick prototypes, custom fits or low-volume parts often fit 3D printing best.

When waste must be low, speed is key, or customization matters, 3D printing wins.

I have seen many successful uses of 3D printing. In small-batch manufacturing. In prototype work. In custom parts for machinery.

Prototypes and fast design cycles

When a design team tests new ideas, they need to see real parts fast. 3D printing shines here.

Designers can change a model in software, press print, and get a physical part in hours or a day. They can test fit, shape, ergonomics. They can iterate quickly. This speed accelerates design cycles.

For prototypes, shape matters more than strength or finish. So printed parts often suffice.

Custom parts and low-volume production

When a part is unique or only needed in small numbers, 3D printing saves cost and time. CNC would need expensive tooling and many CNC hours. Instead, 3D printing makes one or a handful directly.

Examples: custom brackets, fixtures, jigs, housing prototypes, spare parts for old machines, one-off parts for special machines. These benefit from customization and quick turn around.

Complex geometry and lightweight parts

If a part has complex internal channels, organic shapes, hollow structures, or lightweight needs, 3D printing can do what CNC cannot.

For example:

- Internal cooling channels in metal parts.

- Hollow housings that are light but strong enough for non-critical use.

- Complex curved housings for electronics or drones.

These shapes would be hard or impossible to machine. Or would waste a lot of material.

Low waste and eco‑friendly small runs

3D printing uses only needed material for the part. There is minimal waste compared with cutting away a block. For plastic parts or light use metal parts, this can reduce cost and environmental impact.

Rapid repair and spare parts supply

Sometimes a part breaks in remote location. 3D printing allows you to produce spare quickly if you have a CAD file and a printer. No need to wait for raw material blocks or special tooling. This rapid response helps maintenance teams.

Because of these strengths, 3D printing fits jobs where speed, shape, customization matter more than high strength or surface finish.

Where do both methods coexist?

It is tempting to think we must choose one method. I believe that both will continue to work side by side.

In many real world projects, 3D printing and CNC machining complement each other.

In many workflows, 3D printing and CNC work together: printing for shape and prototype, CNC for strength and final finish.

They form a hybrid path to get the best of both worlds.

I have seen shops that use both technologies. Designers print a test part. Then cnc‑machine the final part. Others 3D print plastic prototypes and then use CNC for final metal parts.

Typical hybrid workflow

- Designer draws part in CAD.

- 3D print a prototype with plastic or low‑cost material.

- Test the prototype: fit, function, ergonomics.

- Adjust design if needed.

- Finalize material (metal or high‑grade plastic).

- Use CNC machining to make final parts with full strength and finish.

This hybrid flow saves time and reduces waste. It also reduces risk of tooling mistakes before final production.

Mixed batch production

In some orders you may need both custom pieces and many identical parts. You can 3D print the custom ones. Then CNC machine the rest in batch. This mix keeps cost down and ensures quality where needed.

Complex parts with external and internal features

If a part has complex internal geometry plus areas needing strength or tight tolerance, you might split the job. Use 3D printing for the internal complex part. Use CNC for external surfaces that need precision and strength.

Cost and turnaround optimization

If you need one part now and maybe more later, you can 3D print first. Send it to test. If all is good and demand rises, switch to CNC for mass production. This approach offers flexibility and cost control.

Industry examples

| Industry / Use Case | Why hybrid method works |

|---|---|

| Automotive prototyping + low volume parts | Print prototype for shape test, CNC metal for strong parts |

| Machinery maintenance & spare parts | Print custom spare fast, then CNC for durable spare if repeated demand |

| Consumer electronics housing + metal frame | 3D print plastic housing prototypes for design, CNC metal shell for final product |

| Custom tooling and jigs | 3D print jig for trial, CNC machine final jig when design is fixed |

These examples show that coexistence is common.

I believe that future manufacturing will often mix both methods.

Conclusion

3D printing will not fully replace CNC machining.

Each method serves different needs.

In many cases they work together.

The future lies not in replacing but in combining them smartly.

Best manufacturing picks the right tool for each job.